Heater "pumping" when in standby

-

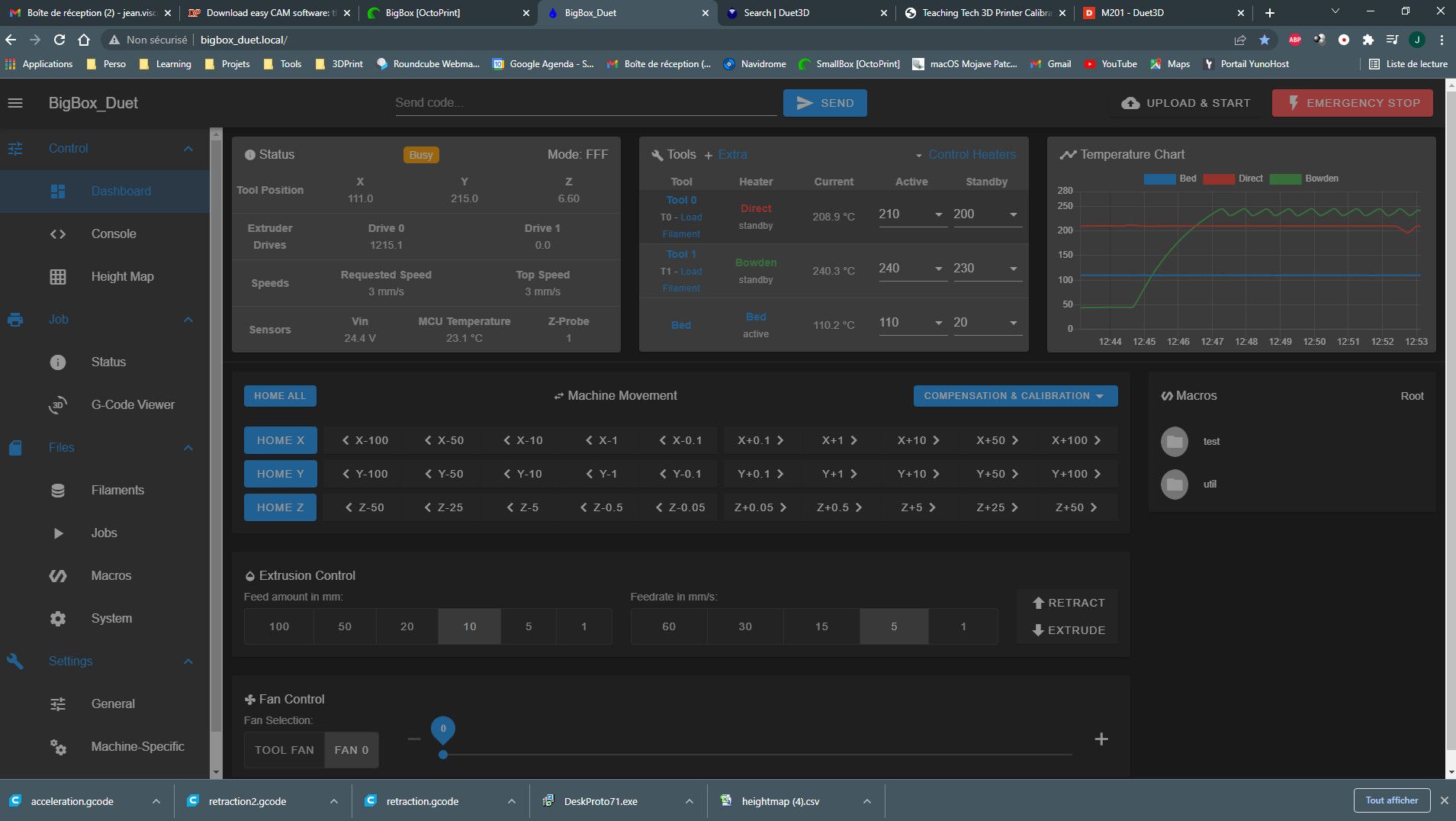

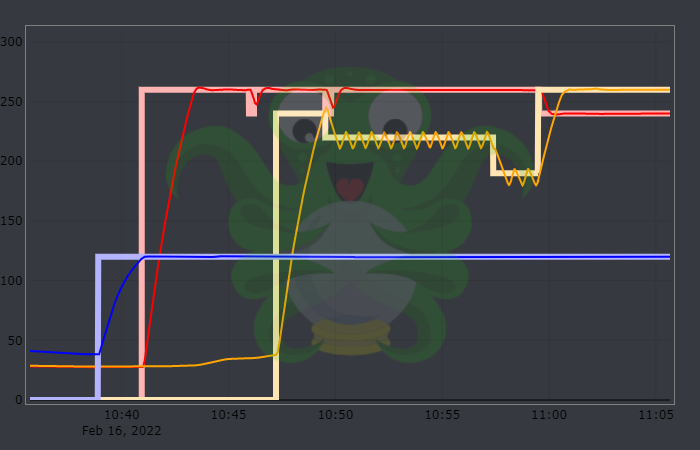

As shown in the picture, the yellow heater "pumps" when in standby, then goes back to normal as it activated again. No problem so far since I never saw an active heater pumping.

Both heaters have been tuned with M303 then M500 stored parameters in config_override.g

-

Can you give some more details?

-

@phaedrux Here is the config.g & config_override.g

The heater that pumps is H2

config.g

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Fri Jan 07 2022 10:08:48 GMT+0100 (heure normale d’Europe centrale); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"BigBox_Duet" ; set printer name; Network

M552 S1 P"XXXXX" ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; disable FTP

M586 P2 S1 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes forwards

M569 P4 S0 ; physical drive 4 goes forwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X160.00 Y360.00 Z1600.00 E304.00:304.00 ; set steps per mm

M566 X600.00 Y600.00 Z30.00 E20.00:20.00 ; set maximum instantaneous speed changes (mm/min)

M203 X8000.00 Y6000.00 Z360.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X400 Y400 Z1200 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

;M208 X0 Y0 Z0 S1 ; set axis minima

M208 X0:330 Y0:240 Z0:300 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z1 S2; Z-Probe

;M558 P5 C"zprobe.in" H5 F120 I1 T6000 ; set Z probe type to unmodulated and the dive height + speeds

M558 P1 C"zprobe.in" I0 H5 R0.5 F340 T6000

;M558 P1 X0 Y0 Z1 H3 F200 T5000 ; Smart IR Z probe, used for homing Z axis, dive height 3mm, probe speed 200mm/min, travel speed 5000mm/min

G31 X-60.0 Y0 Z1.6 P510 ; Set the probe height and threshold (put your own values here)

M557 X10:275 Y5:195 S85 ; define mesh grid; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T50:60 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H2 T50:60 ; set fan 2 value. Thermostatic control is turned on; Heaters

M308 S0 P"bed_temp" Y"thermistor" T100000 B4725 C7.06e-8 A"Bed" ; configure sensor 0 as thermistor on pin bedtemp Semitec 104 GT2 for AC Bed

M950 H0 C"bedheat" T0 A"Bed" Q10 ; create bed heater output on bedheat and map it to sensor 0

M140 H0 ;S80 R60 ; map heated bed to heater 0 , active 80°C, stdby 60°C

M143 H0 S150 ; set temperature limit for heater 0 to 120C

M308 S1 P"spi.cs2" Y"rtd-max31865" A"Direct" ; configure sensor 1 as PT100 on pin spi.cs1

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M570 H1 P5 T20 ; set heater fault detection parameter

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M308 S2 P"spi.cs1" Y"rtd-max31865" A"Bowden" ; configure sensor 2 as PT100 on pin spi.cs2

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M570 H2 P5 T20 ; set heater fault detection parameter

M143 H2 S280 ; set temperature limit for heater 2 to 280C; Tools

;Tool0

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Tool1

M563 P1 D1 H2 F0 ; define tool 1

G10 P1 X-37.61 Y1.44 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; read stored PID parameters

M501config_ovverride.g

; config-override.g file generated in response to M500 at 2022-02-16 09:07

; This is a system-generated file - do not edit

; Heater model parameters

M307 H0 R0.935 K0.408:0.000 D2.93 E1.35 S1.00 B0

M307 H1 R1.942 K0.445:0.129 D5.33 E1.00 S1.00 B0 V24.4

M307 H2 R1.851 K0.261:0.199 D5.67 E1.35 S1.00 B0 V24.4 -

So when you say that it pumps, you're referring to the up and down saw tooth pattern displayed in the gragh?

What does the heater graph in DWC look like?

What does the actual displayed temperature in DWC look like?Is this perhaps an artifact of using octoprint for monitoring?

-

@phaedrux I did not record the graph on DWC since I mainly use Octoprint as a GUI.

I don't think it's an artefact from octoprint but I'll check next time it happens and let you know.

let's see -

-

Firmware version?

-

@audryhome if the temperature is oscillating, the usual fix is to increase the D parameter in the M307 command for the heater concerned. Try increasing it by 30%, and if that doesn't stop it, by 60%. You can send M307 with just the H and D parameters from the console while watching the temperature graph; then when you have established what value you need, edit the corresponding M307 command in config.g.