Prusa new kitchen sink XL printer

-

Not duet related though I am sure a duet would fit.

Prusa are teasing with their upcoming new printer. It seems to include any conceivable feature. Any thoughts?

https://www.youtube.com/watch?v=9peACH52KTo

More info here https://www.prusa3d.com/product/original-prusa-xl-6/

-

@zapta That looks awesome!

-

@th0mpy said in Prusa new kitchen sink XL printer:

@zapta That looks awesome!

It's also a lot of money lol like 3K plus for a fully loaded one

-

I'm really interested in how they are handling the segmented bed, I think that could be a really great option going forward, depending what size of 'tiles' are available, why waste power heating sections of the bed you aren't printing on?

-

@mikebridge said in Prusa new kitchen sink XL printer:

I'm really interested in how they are handling the segmented bed, I think that could be a really great option going forward, depending what size of 'tiles' are available, why waste power heating sections of the bed you aren't printing on?

I agree. I just wonder how well it works in principle when you place a decent conductive material on top which then takes that heat away. Are we likely to see the central bed parts failing before the outer ones. I do like the innovation in this printer.

-

@zapta

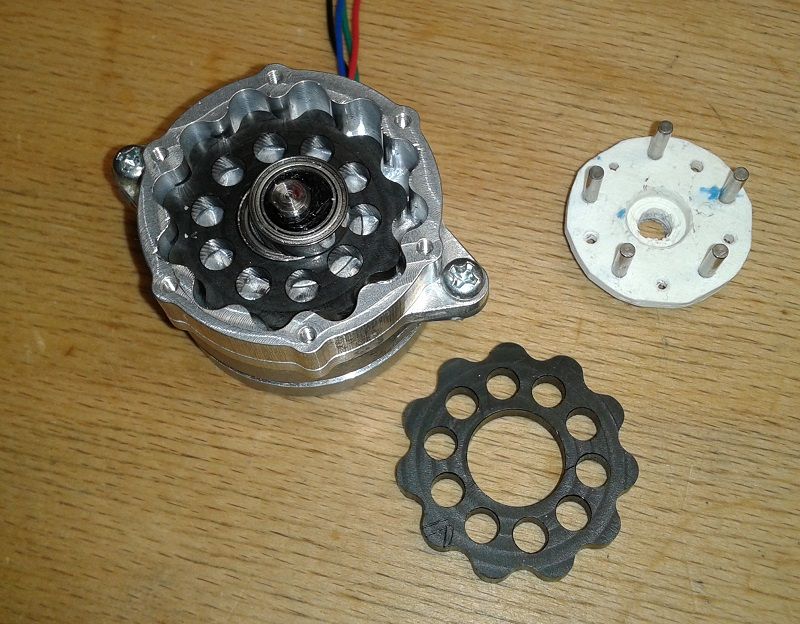

I'm proud to hear their Nextruder uses a Cycloidal drive gear. We've played with it in 2016 already:

Just wondering, what the non-slip drive gear looks like?

-

@o_lampe said in Prusa new kitchen sink XL printer:

@zapta

> I'm proud to hear their Nextruder uses a Cycloidal drive gear. We've played with it in 2016 already:

Just wondering, what the non-slip drive gear looks like?The no-slip gear is just one relatively large driven toothed gear pushing up against two bearings as far as i understood:

-

@exerqtor

That's clever! They seem to have integrated the cycloidal drive into the drive gear. At least the dowel pins it seems... -

Besides the cycloidal geard extruder, the filament path looks like pain in the arse to fiddle the filament in

.

.

An as an mechanical engineer i am not a huge fan of unsupported beams of aluminum hanging in mid air trying to hold up the linear rails and hole printheadassebly.

But ohterwise i am curios to see what else prusa will bring to the table with this printer. Looks like an interesting design of the docking for the tools. -

Well the "beams" are supported more or less up until halfway out, and were not talking any significant load anyways. After all it's just a little 3D printer not a gantry crane

-

@exerqtor I'm wondering how well that filament path is going to handle flexible filaments. I can see getting a wad stuck between the 2 bearings opposing the toothed gear.

-

@mikebridge I agree, I would have thought a Bondtech (or Hemera) style dual drive arrangement would have better grip on a wide range of filaments.

-

@dc42

Prusa couldn't invent a dual drive extruder, since it's already there. They had to do something different -

This printer reminds me of concept cars. More a demonstration of ideas and capabilities rather than a solid and practical design for mass production. Will see next year how it will end up.

-

@o_lampe said in Prusa new kitchen sink XL printer:

They had to do something different

@zapta said in Prusa new kitchen sink XL printer:

This printer reminds me of concept cars.

The heatsink with inbuild load cell falls in the same category. Strain gauge and Piezo sensors were already there, something different had to be made...

-

I don't get the multi zone heated bed. I suppose having smaller "pads" with expansion joints in between would prevent warping due to thermal expansion, but using a kinematic mount is a lot simpler. Then how are the individual pads heated? Presumably each one has its own heater and so each one would need its own temperature sensor. That's a lot of sensors, MOSFETS, and wiring. The build surface would need to be thermally conductive which means that heat will conduct up into the build surface where there are heaters, but equally, heat will conduct down from the build surface where there are no heaters. It seems like a lot of complexity for very little gain.

And if you going to charge circa 3k for a machine, why not build the thing properly instead of using firmware to calibrate out all the build and design flaws?

-

@deckingman said in Prusa new kitchen sink XL printer:

I don't get the multi zone heated bed

Green washing?

Hobbyists, printing tug boats, spiral vases, x-mas ornaments or other useless stuff might feel better with a printer using less energy.

(I count myself in. The only useful? stuff I print are parts for new printers)//edit Sorry, I'm in foul mood lately...Winter is coming

-

i guess prusa learned from their mistake with the dual drive gear . Its causing more issues then its supposed to solve .

I agree that 2 idler wheels will probably cause issues with flexible filaments , maybe there is something i don't see , don't know . -

The multi zone heater system with expansion joints is a big question mark for me as well. I don't quite get the expansion joint theory .... isn't the bed a single piece? How does the expansion joint on the heater help to get a stable bed? Seems to me you would still need a kinematic mount for the bed or else live with the results of expansion of the build surface.

How do individual heaters help if the bed is a big heat conductor unless it is fairly thin?

I can understand multiple heaters on a giant build surface but we are not talking 'giant' here.

Many questions ... -

@jens55 Methinks it's just a marketing ploy. It'll likely be trumpeted as an innovation but that doesn't mean it's of any use. Just like sensor less homing. The real reason for that is to save Prusa the cost of a switch and an bit of wire on all their machines. The fact that it will never be as reliable or repeatable as a simple switch is irrelevant. To many people, the very fact that Prusa uses it must mean it's the dog's danglies.