Connecting and reading a pulse generating encoder

-

@pfn yeah that is indeed for the new CF 1.1 which uses a pulse counter on the unit. In clipper they dev a piton module so macros are gone and the porting to RRF is no more an option

I like your idea. And yeah i'm in on the global variables (that was my target too) but i miss the way to count the pulses event (at that speed too)

Could you please elaborate more on the wiring and how would you read (or detect the trigger in that logic) the pulse.

On the printhead (extruder) there is a (hall sensor) filament sensor which detects the filament reached past the gears but that is something manageable which (i thinnk) is doable

thanks(p.s. Mini 5+ it is in my case)

-

@oc_geek how is it interfaced? What protocol?

-

@oc_geek the output signal pin from the TCRT5000 would go into any of the ioN.in pins

Configure the pin as appropriate with

M950 J0 C"ioN.in"

M581 P0 T0 ...Create /sys/trigger0.g and add code in there to do whatever is needed.

I haven't tried putting together an ercf yet, but it's on my list of things to investigate.

-

@t3p3tony Hi Tony, thanks for coming by

I have to confess i'm totally ignorant. I'm just trying to figure out if there is a way for RRF to use the Enraged Rabbit MMU 1.1 (Voron)

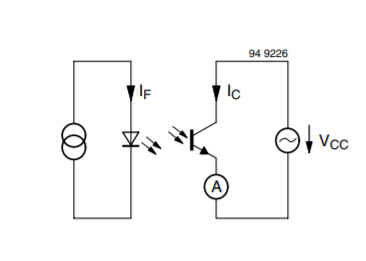

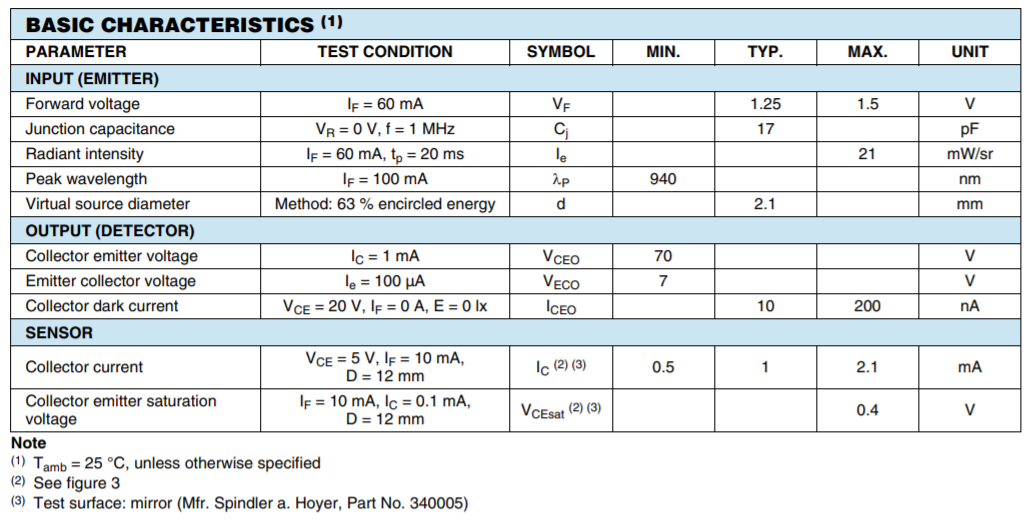

The pulse sensor is a TCRT5000 (IR Infrared)

TCRT5000 infrared reflective sensor

Detects the reflected distance: 1mm ~ 25mm Applicable

The working voltage: 5V

The output format: digital signal (0 and 1)I suppose it just sends digital 0 or 1 (without a specific protocol)

Any advice help is very much appreciated in advance

-

@pfn

Thanks for the explanation.I realize just now that this is the same "trick" i use for the filament sensor which is on my Mini5+ while i use the 1LC as tool board. Makes sence

That way you basically invoke the trigger and add 1 to the counter. Good idea. I hope it can stand the 500 Hz rate though... @T3P3Tony (do you know ?)

So couple of macros (count and reset) and we shall be in the game

I'm at the same stage of yours atm.

I have bought some of the key parts but have not yet printed it.

I hope we RRF folks are in the game too

-

@oc_geek so this is generating pulses at 500hz? There must be more too it if there is a pulse counter on the unit itself.

-

@oc_geek 500Hz rate? why is it so high? It should only trigger once per unit distance (which shouldn't be much lower than about 1mm per pulse...)

-

@oc_geek yeah the TCRT5000 is a reflective optical switch or potentially a distance sensor depending on how it was used. is there a rotating element with slots in?

-

@oc_geek you could use a frequency divider to reduce pulse count/second . They will reduce by 2,4,8 a.s.f. depending on their setting.

A small ATtiny or PIC processor can do the trick, too.

Then, when Duet gets triggered , add 2,4,8 pulses to the equation instead of 1.In any case make sure, the pulse counting macro is as short as possible. Otherwise you might miss incoming pulses.

Write another macro to read the global pulsecounter and go on from there. -

@t3p3tony as far as i could see from the Discord ERCF 1.1 discussion it reads a Bondtech gear which rotates with filament

Filament running at 20 mm / sec so that's where the 200 - 500 Hz comes from (i'm just reporting what i was told) -

@oc_geek so whats the pulses/mm of this sensing arrangement. There is existing code for using a pulse based filament monitor

https://duet3d.dozuki.com/Wiki/M591#Section_M591_RepRapFirmware_Num_3Type 7

-

@oc_geek what's the purpose of measuring the counts? Is it to detect if the mechanism is jammed?

With a simple pulse generating encoder, you will not be able to determine in which direction the mechanism is moving. Might that be a problem?

-

@dc42 i understood they use it to determine the filament position (real travel distance) when loading a specific filament in the MMU down to the tool head

With the encoder they say it is possible to meisure with a precision of 1 mm

Direction is derived by other means and hold by other variablesAll that said would it be possible to use triggers to follow it up @ e.g. 250 Hz ?

-

@t3p3tony i saw that but it wont be possible to inquire the position nor to reset it (unless i'm reading it wrong)

-

The Klipper firmware seems to work fine with the ERCF, so perhaps will be valuable to check their code? It wIll gives more understanding towards what oc'geek and many others trying to get. (The voron - duet community is big )

That is the link to the PCB for ERCF:

https://github.com/Tircown/ERCF-easy-brd

Link to the project:

-

@dan1990 rightly said

in particular the part responsible for the Pulse Generating encoder is a Klipper module written in python

-

@oc_geek why would you need 250hz? 1 pulse per mm, feed rates are usually like 10mm/s at most... (browsing that code, it looks like it's set at 1.5mm/pulse and something like 100mm/s feed rate, it's probably reasonable enough?)

-

@pfn as i wrote this came from the Author of the unit itself... it's not that i need something..

The sensor is used ONLY when loading / unloading the chosen (between nine) filament to the tool to make sure it arrives where intended and does not jam the unit and so on...

I think they do that faster than a print feed rate to reduce the overall print time...(e.g. 1000 filament changes in a print would matter..)that said i did not got any data point from the Duet team on which rates (Hz) are reachable using a trigger... or any other offered solution...

-

@oc_geek it may be too fast to push 250 triggers a second (even though it should be brief). 250 triggers a second would be something like 375mm/s feed rate, is the ercf really capable of that? In any case, if RRF isn't capable of that speed of triggering, you can solve it with several means.

-

Decrease the pulse resolution, i.e. remix the encoder wheel so that pulses are every 3mm rather than 1.5, decrease resolution until it is manageable, if it is an issue.

-

Even easier is to simply lower the feed rate , 100mm/s is already really fast, adjust until pulse counts are manageable.

I'd prefer to do 1. Anyhow, if you already have a smart filament sensor handy, it wouldn't be very hard to test to see what kind of rate you can achieve, yank filament through and see how many triggers you can capture.

As for the duet team not giving a number, I'm not sure anyone even tests this scenario...

-

-

@pfn yeah will have to check as you say

Option 1 is not possible as the "encoder wheel" is actually a metal Bondtech gear (as i wrote before below)

Option 2 seems to be the only practical possibility

Also the challenge will be to port the Klipper python module into RRF Marcos...