Toolboard Heater Fault

-

@dhusolo said in Toolboard Heater Fault:

M307 H1 R2.330 C273.8:126.9 D12.41 S1.00 V25.7 ; Set PID for Hotend .4Bmm nozzle POST RRF 3.2.3

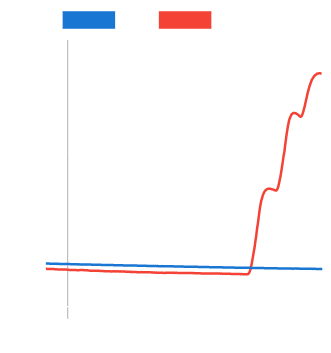

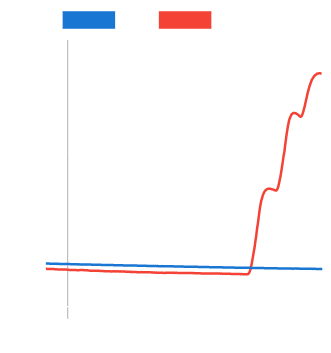

I'm surprised the tuning thinks your hotend has 12 seconds of dead time, yet the graph shows it hitting 90c quite quickly.

Have you tried PID tuning on 3.3 RC3 yet? Might be worth deleting your M307 line and re-tuning.

What kind of thermistor do you have?

If you send M98 P"config.g" do you get any errors back?

-

@phaedrux Yes I noticed it heating up quite quickly however that might be due to the fact that it's a liquid cooled setup.

I haven't deleted the M307 line and re-tuning but I have tried PID tuning a few times with the existing M307.

These are the thermistors I'm using. I noticed these are 3950 where I had 4725 in my M308 config however I've been using the same thermistor with the same B value for a few months. link

When I do M98 P"config.g" I do not get any errors

-

Let us know how a fresh PID tuning works out with the corrected B value. It will likely give you a slightly more accurate temp reading. So if you're used to printing at a certain temp now that might change slightly.

-

@phaedrux I just ran it again after clearing

M307.M303 T0 F0.9 S215

These are the results

M307 H1 B0 R2.824 C282.4:110.0 D9.82 S1.00 V25.7 -

@dhusolo Why F0.9?

Fnn (RRF 3.3beta3 and later) Fan PWM to use when the print cooling fan is turned on (ignored if the T parameter is not present), default 1.0. Use a lower value if youpr printer uses a powerful print cooling fan that you do not normally run at full PWM.

-

@phaedrux tunes with Fan on at 90%

-

M307 H1 B0 R2.824 C282.4:110.0 D9.82 S1.00 V25.7Vs

M307 H1 R2.330 C273.8:126.9 D12.41 S1.00 V25.7Now the quetion is, how does it perform?

-

@phaedrux No change. Started heating to 220C from 30C. It faults once it gets to about 90c. Reset fault and continue heating right away. This time it gets to 180c and faults. Reset again and it'll heat the rest of the way.

-

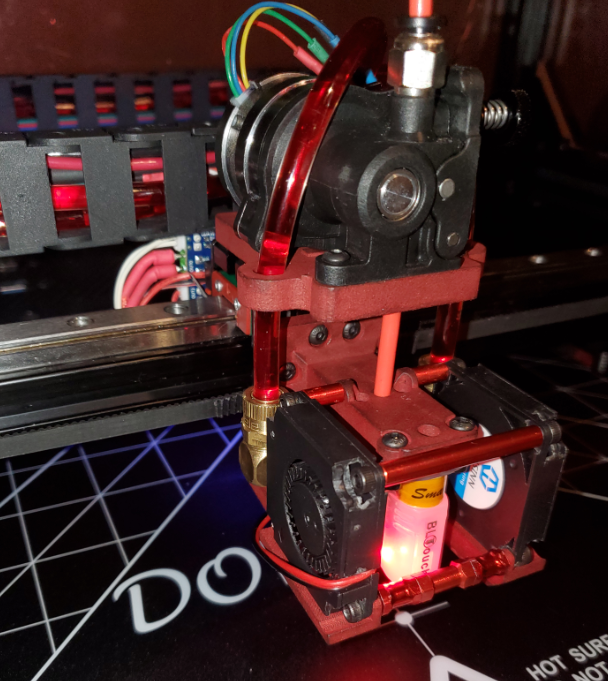

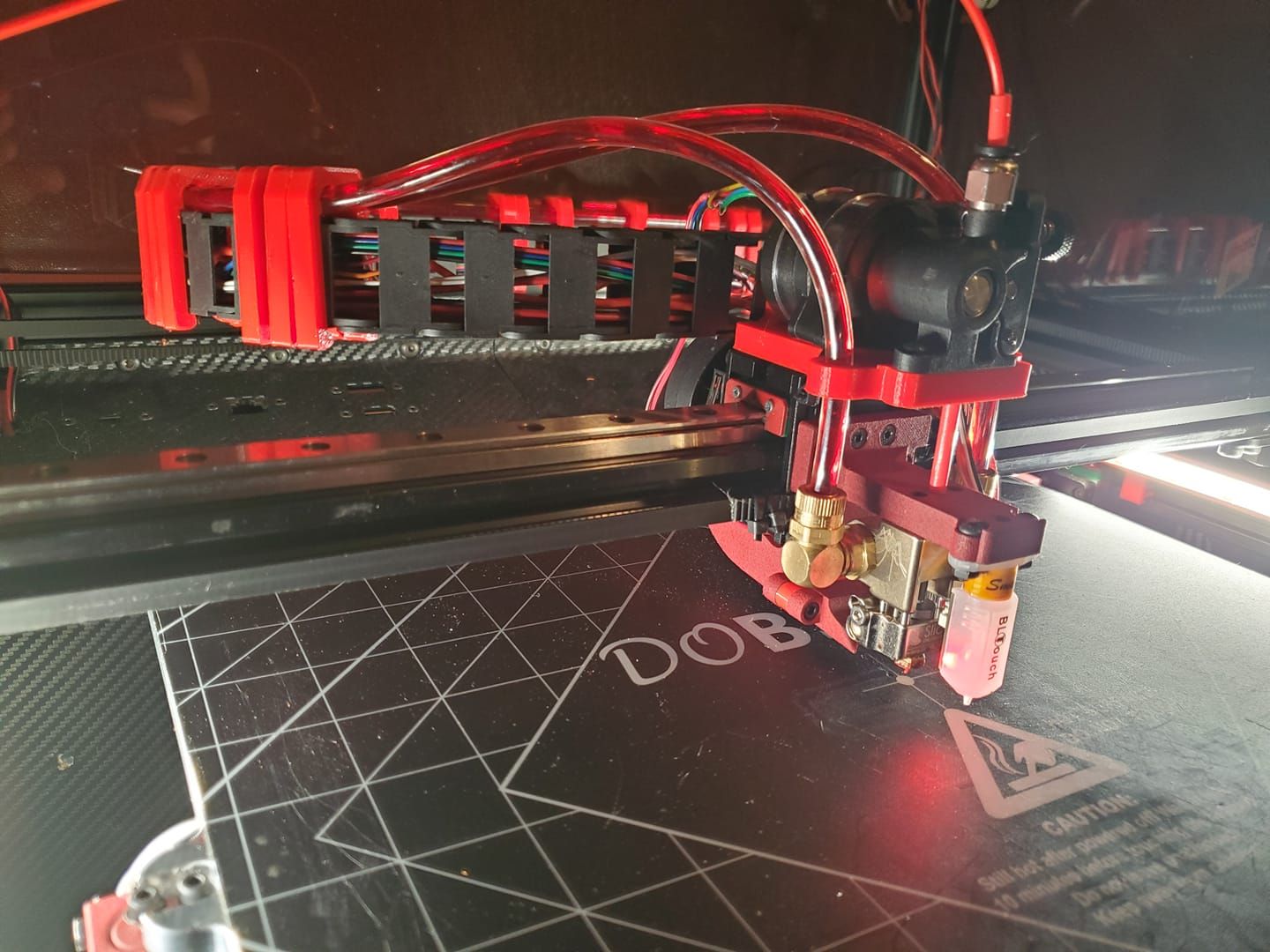

Can you post a photo of the hotend itself?

Is the fan on when heating? Have you tried tuning the heater without the fan? -

@phaedrux I ran PID tuning again without the "F" parameter and I got

M307 H1 B0 R2.837 C252.0:103.7 D9.60 S1.00 V25.7

previously with the layer fan on it was

M307 H1 B0 R2.824 C282.4:110.0 D9.82 S1.00 V25.7

-

What does the hot block look like?

Did tuning without the F param help at all?

-

@dhusolo said in Toolboard Heater Fault:

@phaedrux No change. Started heating to 220C from 30C. It faults once it gets to about 90c. Reset fault and continue heating right away. This time it gets to 180c and faults. Reset again and it'll heat the rest of the way.

I'm not sure if it helps, but I recently had such a heating curve with the same error. The solution was a loose Crimp on the Duet Board, so I would say double-check the thermistor wiring with the crimps.

-

@siam Thanks for the suggestion. I suspected bad crimps so I re-did them just to make sure they had a good connection. The curve is due to the hotend going to a fault state and stops heating. I clear the fault and start heating again

-

@phaedrux It's an older design but for the most part the only thing changed between this and my current setup is now I'm using twin blower fans instead of 1

-

I've found out that if I heat in increments it doesn't fault. If I go directly to 210 it'll fault. It didn't fault if I set it to 80c, wait for it to heat up, set it to 160c, wait to heat up, than set to 210.

-

@dhusolo said in Toolboard Heater Fault:

M307 H1 B0 R2.824 C282.4:110.0 D9.82 S1.00 V25.7

-

From those parameters, I think your hot end must have a high thermal mass, a high powered heater, and good insulation. However, turning on the print cooling fan cools the heater a lot. Does that sound right?

-

Please run M307 H1 and check that it reports that those are the parameters.

-

I suggest you try reducing the R parameter. Too high and it will fault while heating up; too low and the temperature will overshoot. Try R2.0.

-

-

@dc42 It's a mosquito liquid hotend from Slice Engineering. Yesterday I received a new thermistor and heater cartridge from them for that block. I double checked the crimps on the thermistor JST connectors and the wire ferrules on the heater cartridge are good. I don't think it's the cooling fan though. I re-ran PID tuning without the fan and this is the result.

M307 H1 B0 R3.722 C283.2:94.4 D8.95 S1.00 V25.7

This is my sensor settings

M308 S1 P"20.temp0" Y"thermistor" A"Hotend" T100000 B3950 C7.06e-8M307 H1

Heater 1 model: heating rate 3.722, cooling time constant 283.2/94.4, dead time 8.95, max PWM 1.00, calibration voltage 25.7, mode PID Computed PID parameters: setpoint change: P5.4, I0.106, D33.6, load change: P5.4, I0.263, D33.6mosquito liquid

50w heater cartridge

thermistor high temperature -

@dhusolo I have the same problem with dyze extruder, something new about your PID tuning ?

-

@tom33 Nothing new that I can know of. I've been dong the same method for 2 years now

-

@dhusolo you and I have pretty much the same hardware; I don’t see any of that behavior. I’m perplexed.