@CaLviNx seriously stop commenting. I do beta testing and bug fixing for a living. I took the steps I did for a reason. Everyone else has been trying to help while all you've been doing is throwing jabs in and out of this thread. I don't need you to tell me what the "smart approach" is because "the whole point of the exercise" is to figure out what happened and to see if I could fix it, not applying a band-aid.

Best posts made by dhusolo

-

RE: Duet 3 SBC DCS has stoppedposted in Beta Firmware

-

RE: LIS3DH accelerometer to duet 3 mini 5+ wifiposted in Duet Hardware and wiring

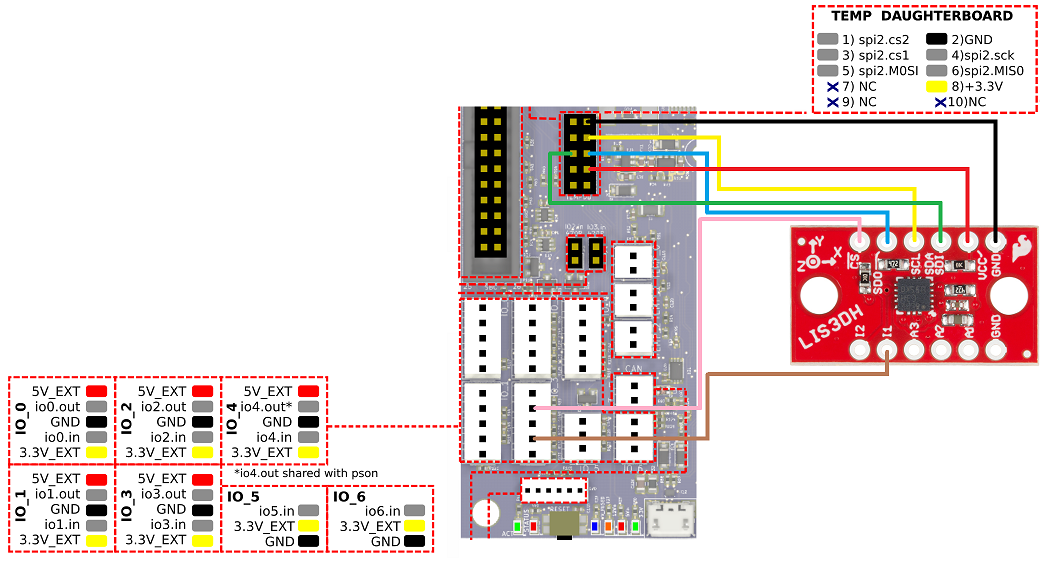

@ratrig0331 It tells you what pin on the accelerometer plugs into what pin on the Duet 3 Mini.

-

RE: Upgrade gone badposted in Firmware installation

@oliof in the end it was solved by reflashing the firmware with bossa. He was using a 10 foot cable. Told him to use a shorter USB cable and it worked.

-

RE: Duet 3 RRF 3.1.1 SBC USB webcamposted in Duet Web Control

@Phaedrux Actually I just tried it out and it worked without a hitch. Took probably 5 minutes

-

RE: Duet 3 SBC DCS has stoppedposted in Beta Firmware

So it happened again. I swapped to a Raspberry Pi 4 with new firmware.

11/6/2020, 12:04:08 AM Cancelled printing file 0:/gcodes/a1.gcode, print time was 0h 20m 11/6/2020, 12:04:08 AM Warning: Controller has been reset 11/5/2020, 11:48:41 PM Height map saved to file heightmap.csv 11/5/2020, 11:48:41 PM 16 points probed, min error -0.018, max error 0.070, mean 0.034, deviation 0.027 11/5/2020, 11:48:41 PM Leadscrew adjustments made: -0.027 -0.025 -0.033, points used 3, (mean, deviation) before (-0.028, 0.003) after (-0.000, 0.000) 11/5/2020, 11:48:41 PM Leadscrew adjustments made: -0.059 -0.023 -0.016, points used 3, (mean, deviation) before (-0.031, 0.014) after (0.000, 0.000) 11/5/2020, 11:48:41 PM Leadscrew adjustments made: -0.022 -0.039 -0.054, points used 3, (mean, deviation) before (-0.039, 0.010) after (0.000, 0.000) 11/5/2020, 11:46:07 PM Height map loaded from file heightmap.csv 11/5/2020, 11:44:01 PM M32 "0:/gcodes/a1.gcode" File 0:/gcodes/a1.gcode selected for printing11/6/2020, 12:12:01 AM M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.1.1 running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-956L2-G43S8-6J9D0-3S46T-9U2LF Used output buffers: 1 of 40 (13 max) === RTOS === Static ram: 154604 Dynamic ram: 163392 of which 64 recycled Exception stack ram used: 544 Never used ram: 74612 Tasks: ETHERNET(blocked,824) NETWORK(ready,1960) HEAT(blocked,1188) CanReceiv(suspended,3820) CanSender(suspended,1420) CanClock(blocked,1436) TMC(blocked,60) MAIN(running,2672) IDLE(ready,76) Owned mutexes: === Platform === Last reset 03:23:27 ago, cause: power up Last software reset at 2020-11-05 20:48, reason: User, spinning module LinuxInterface, available RAM 74612 bytes (slot 3) Software reset code 0x0010 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0444a000 BFAR 0x00000000 SP 0xffffffff Task MAIN Error status: 0 MCU temperature: min 39.7, current 39.9, max 41.4 Supply voltage: min 24.3, current 24.6, max 24.7, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.1, max 12.2, under voltage events: 0 Driver 0: standstill, reads 17162, writes 4 timeouts 0, SG min/max 0/160 Driver 1: standstill, reads 17162, writes 4 timeouts 0, SG min/max 0/400 Driver 2: standstill, reads 17162, writes 4 timeouts 0, SG min/max 0/384 Driver 3: standstill, reads 17162, writes 4 timeouts 0, SG min/max 0/1023 Driver 4: standstill, reads 17162, writes 4 timeouts 0, SG min/max 0/1023 Driver 5: standstill, reads 17162, writes 4 timeouts 0, SG min/max 0/1019 Date/time: 2020-11-06 00:12:00 Slowest loop: 9.38ms; fastest: 0.21ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === Hiccups: 0(0), FreeDm: 375, MinFreeDm: 322, MaxWait: 302820ms Bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves: 3599, completed moves: 3599, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP* is ready with "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon* is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 0.77ms; fastest: 0.03ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions HTTP sessions: 0 of 8 - Ethernet - State: establishingLink Error counts: 0 0 0 0 0 Socket states: 0 0 0 0 0 0 0 0 === Filament sensors === Extruder 0 sensor: ok === CAN === Messages sent 7459, longest wait 0ms for type 0 === Linux interface === State: 0, failed transfers: 8 Last transfer: 19ms ago RX/TX seq numbers: 2795/56430 SPI underruns 13, overruns 11 Number of disconnects: 3 Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.1.1 Code buffer space: 4096 Configured SPI speed: 8000000 Hz Full transfers per second: 32.12 -

RE: BLV MGN Cube Neopixel Questionposted in Duet Hardware and wiring

You should post this on the Facebook page as their's more users familiar with the BLV Cube and the creator of the sketch is on there as well.

-

RE: Duet 3 RRF 3.1.1 SBC USB webcamposted in Duet Web Control

@Phaedrux Thanks!

Do you know if this instructable would work?

How-to-Make-Raspberry-Pi-Webcam-Server-and-Stream -

RE: Duet 3 SBC DCS has stoppedposted in Beta Firmware

Disconnected panel due

11/6/2020, 5:23:22 PM Connection established 11/6/2020, 5:21:46 PM Connection interrupted, attempting to reconnect... DCS has been stopped 11/6/2020, 5:21:16 PM Cancelled printing file 0:/gcodes/a1.gcode, print time was 0h 19m 11/6/2020, 5:21:15 PM Warning: Controller has been reset 11/6/2020, 5:06:52 PM Height map saved to file heightmap.csv11/6/2020, 5:23:59 PM M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.1.1 running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-956L2-G43S8-6J9D0-3S46T-9U2LF Used output buffers: 1 of 40 (13 max) === RTOS === Static ram: 154604 Dynamic ram: 163392 of which 140 recycled Exception stack ram used: 544 Never used ram: 74536 Tasks: ETHERNET(blocked,832) NETWORK(ready,1968) HEAT(blocked,1188) CanReceiv(suspended,3820) CanSender(suspended,1384) CanClock(blocked,1436) TMC(blocked,68) MAIN(running,2672) IDLE(ready,76) Owned mutexes: === Platform === Last reset 03:50:47 ago, cause: power up Last software reset at 2020-11-05 20:48, reason: User, spinning module LinuxInterface, available RAM 74612 bytes (slot 3) Software reset code 0x0010 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0444a000 BFAR 0x00000000 SP 0xffffffff Task MAIN Error status: 0 MCU temperature: min 39.5, current 39.8, max 40.3 Supply voltage: min 24.3, current 24.6, max 24.8, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.0, current 12.1, max 12.1, under voltage events: 0 Driver 0: standstill, reads 32788, writes 7 timeouts 0, SG min/max 0/1023 Driver 1: standstill, reads 32787, writes 8 timeouts 0, SG min/max 0/226 Driver 2: standstill, reads 32788, writes 7 timeouts 0, SG min/max 0/1023 Driver 3: standstill, reads 32788, writes 7 timeouts 0, SG min/max 0/179 Driver 4: standstill, reads 32788, writes 7 timeouts 0, SG min/max 0/175 Driver 5: standstill, reads 32788, writes 7 timeouts 0, SG min/max 0/127 Date/time: 2020-11-06 17:23:58 Slowest loop: 9.29ms; fastest: 0.21ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === Hiccups: 0(0), FreeDm: 375, MinFreeDm: 323, MaxWait: 541330ms Bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves: 3364, completed moves: 3364, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP* is ready with "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon* is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 0.76ms; fastest: 0.03ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions HTTP sessions: 0 of 8 - Ethernet - State: establishingLink Error counts: 0 0 0 0 0 Socket states: 0 0 0 0 0 0 0 0 === Filament sensors === Extruder 0 sensor: ok === CAN === Messages sent 5531, longest wait 0ms for type 0 === Linux interface === State: 0, failed transfers: 22 Last transfer: 20ms ago RX/TX seq numbers: 1766/48405 SPI underruns 38, overruns 14 Number of disconnects: 2 Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.1.1 Code buffer space: 4096 Configured SPI speed: 8000000 Hz Full transfers per second: 32.0311/6/2020, 5:24:21 PM M98 P"config.g" HTTP is enabled on port 80 FTP is disabled TELNET is disabled Warning: M307: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 351C -

RE: 4 Wires BLTouch Connectionposted in Duet Hardware and wiring

I connected the 2 ground wires together and it's been fine

-

RE: Duet 3 SBC DCS has stoppedposted in Beta Firmware

I haven't loaded my config file but I flashed Duet3Firmware_MB6HC.bin through Bossa. It looks like it's communicating with the RPI again.

M122

m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.1.1 running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-956L2-G43S8-6J9D0-3S46T-9U2LF Used output buffers: 1 of 40 (10 max) === RTOS === Static ram: 154604 Dynamic ram: 161360 of which 20 recycled Exception stack ram used: 236 Never used ram: 76996 Tasks: NETWORK(ready,1980) HEAT(blocked,1452) CanReceiv(suspended,3820) CanSender(suspended,1488) CanClock(blocked,1436) TMC(suspended,252) MAIN(running,5184) IDLE(ready,76) Owned mutexes: === Platform === Last reset 00:09:59 ago, cause: power up Last software reset at 2020-11-05 20:48, reason: User, spinning module LinuxInterface, available RAM 74612 bytes (slot 3) Software reset code 0x0010 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0444a000 BFAR 0x00000000 SP 0xffffffff Task MAIN Error status: 0 MCU temperature: min 15.0, current 25.8, max 25.9 Supply voltage: min 0.2, current 0.3, max 0.3, under voltage events: 0, over voltage events: 0, power good: no 12V rail voltage: min 0.1, current 0.1, max 0.2, under voltage events: 0 Driver 0: ok, reads 0, writes 0 timeouts 0, SG min/max 0/0 Driver 1: ok, reads 0, writes 0 timeouts 0, SG min/max 0/0 Driver 2: ok, reads 0, writes 0 timeouts 0, SG min/max 0/0 Driver 3: ok, reads 0, writes 0 timeouts 0, SG min/max 0/0 Driver 4: ok, reads 0, writes 0 timeouts 0, SG min/max 0/0 Driver 5: ok, reads 0, writes 0 timeouts 0, SG min/max 0/0 Date/time: 2020-11-08 14:26:06 Slowest loop: 2.36ms; fastest: 0.13ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === Hiccups: 0(0), FreeDm: 375, MinFreeDm: 375, MaxWait: 0ms Bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === Heat === Bed heaters = -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP* is ready with "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon* is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 1.03ms; fastest: 0.01ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions HTTP sessions: 0 of 8 - Ethernet - State: disabled Error counts: 0 0 0 0 0 Socket states: 0 0 0 0 0 0 0 0 === CAN === Messages sent 0, longest wait 0ms for type 0 === Linux interface === State: 0, failed transfers: 0 Last transfer: 12ms ago RX/TX seq numbers: 19460/19461 SPI underruns 0, overruns 0 Number of disconnects: 0 Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.1.1 Code buffer space: 4096 Configured SPI speed: 8000000 Hz Full transfers per second: 5.64M122 DSF

m122 DSF === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.1.1 running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-956L2-G43S8-6J9D0-3S46T-9U2LF Used output buffers: 1 of 40 (12 max) === RTOS === Static ram: 154604 Dynamic ram: 161360 of which 20 recycled Exception stack ram used: 236 Never used ram: 76996 Tasks: NETWORK(ready,1980) HEAT(blocked,1452) CanReceiv(suspended,3820) CanSender(suspended,1488) CanClock(blocked,1436) TMC(suspended,252) MAIN(running,4512) IDLE(ready,76) Owned mutexes: === Platform === Last reset 00:12:41 ago, cause: power up Last software reset at 2020-11-05 20:48, reason: User, spinning module LinuxInterface, available RAM 74612 bytes (slot 3) Software reset code 0x0010 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0444a000 BFAR 0x00000000 SP 0xffffffff Task MAIN Error status: 0 MCU temperature: min 25.6, current 25.8, max 26.0 Supply voltage: min 0.3, current 0.3, max 0.3, under voltage events: 0, over voltage events: 0, power good: no 12V rail voltage: min 0.1, current 0.2, max 0.2, under voltage events: 0 Driver 0: ok, reads 0, writes 0 timeouts 0, SG min/max not available Driver 1: ok, reads 0, writes 0 timeouts 0, SG min/max not available Driver 2: ok, reads 0, writes 0 timeouts 0, SG min/max not available Driver 3: ok, reads 0, writes 0 timeouts 0, SG min/max not available Driver 4: ok, reads 0, writes 0 timeouts 0, SG min/max not available Driver 5: ok, reads 0, writes 0 timeouts 0, SG min/max not available Date/time: 2020-11-08 14:28:49 Slowest loop: 1.97ms; fastest: 0.13ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === Hiccups: 0(0), FreeDm: 375, MinFreeDm: 375, MaxWait: 0ms Bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === Heat === Bed heaters = -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP* is ready with "M122 D0 S0 F0" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon* is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 1.03ms; fastest: 0.01ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions HTTP sessions: 0 of 8 - Ethernet - State: disabled Error counts: 0 0 0 0 0 Socket states: 0 0 0 0 0 0 0 0 === CAN === Messages sent 0, longest wait 0ms for type 0 === Linux interface === State: 0, failed transfers: 0 Last transfer: 12ms ago RX/TX seq numbers: 24793/24794 SPI underruns 0, overruns 0 Number of disconnects: 0 Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.1.1 Code buffer space: 4096 Configured SPI speed: 8000000 Hz Full transfers per second: 32.80

Latest posts made by dhusolo

-

RE: HY VFD controlled by Duet 3 Miniposted in CNC

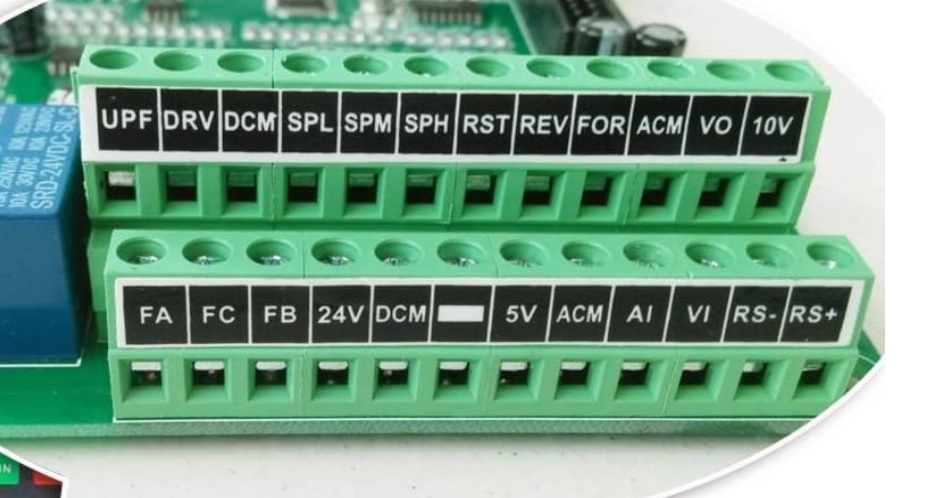

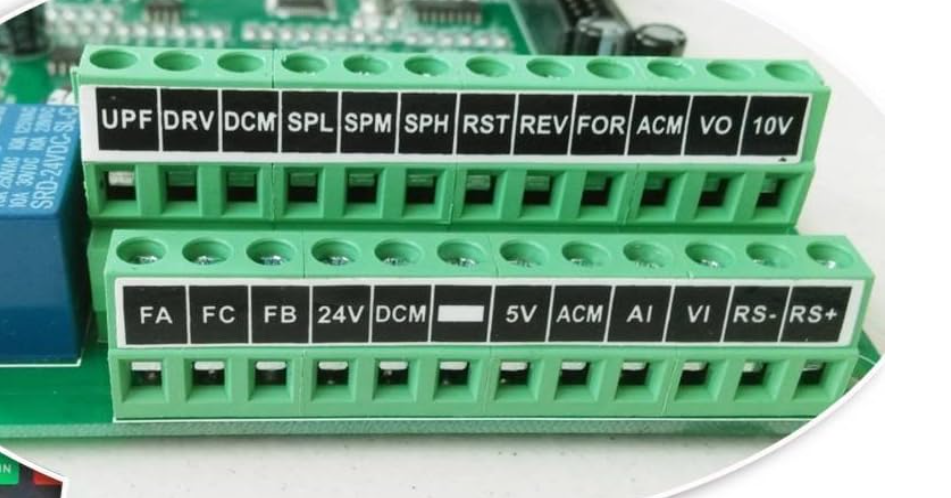

@dc42 Yes I have. The connections are

PWM Input - > VFD GND Pin

PWM Input + > VFD(out6_buff) pin

Power Supply + > 12v+ next to VFD pins

Power Supply - > 12v- next to VFD pins

Voltage output - (GND) goes to ACM

Voltage output + (AO) goes to VI(I've also tried AI)My config is

M950 R0 C"0.vfd+0.io4.out" Q3000 L24000 ; create spindle #0 connected to vfd pin and 24k rpm at full PWM M563 P1 S"Spindle" R0 ; create tool #1 with spindle 0 M453 ; set cnc mode M568 P1 F0 T1 M3 T1 S0 M5 -

RE: HY VFD controlled by Duet 3 Miniposted in CNC

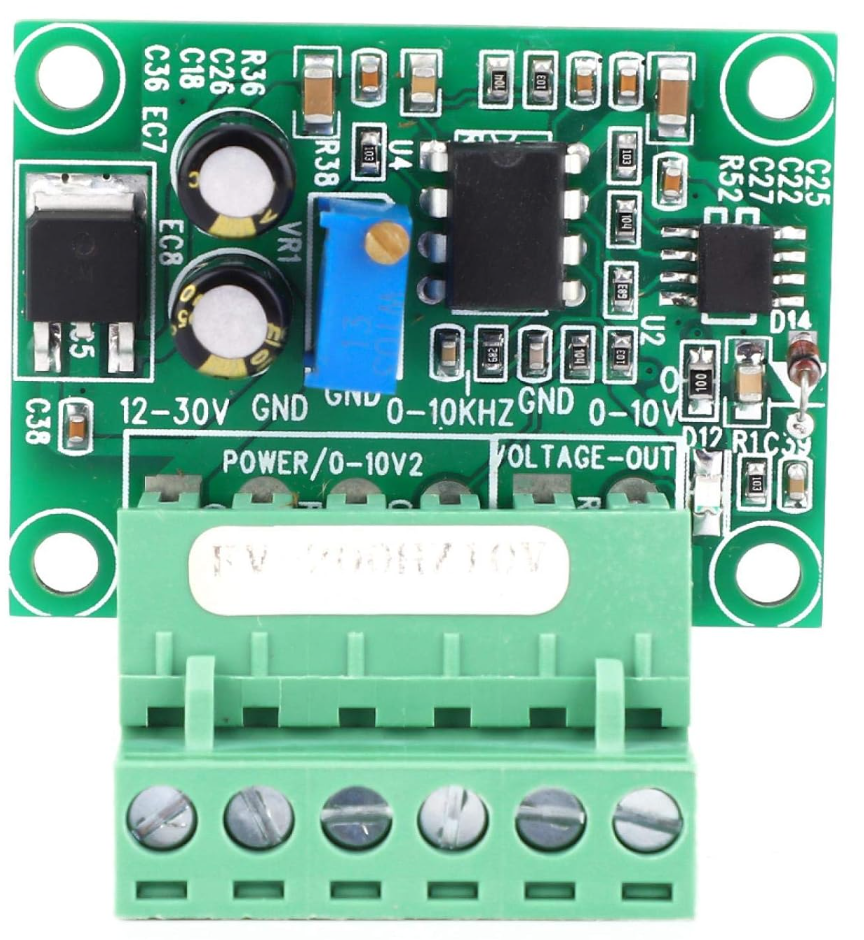

@dc42 You sir are correct. I did get the wrong board. I installed an actual PWM to Voltage converter and wired it up. This is the one I'm using now

Voltage output - (GND) goes to ACM

Voltage output + (AO) goes to VI(I've also tried AI)I have a relay connected

NO > DCM

COM > FOR

Right now I'm switching it with a macro but eventually I'll get it configured to automatically switch when the drive is working correctly. I know the relay is working because when I switch it on the FOR LED on the VFD goes to solid.

I set:

PD001 = 1

PD002 = 1

PD070 = 0

I've moved the jumper to J1 enabling external potentiometer. I've tested the AO and GND and I am getting about 4.8v at 12k RPMs. But the VFD isn't recognizing the signal from the PWM converter -

RE: HY VFD controlled by Duet 3 Miniposted in CNC

@dc42 From what I can see it's the HY02D211B VFD. I've got it kind of working. I can control the speed from S6000 to S7000 but it'll max out at 7000, even if I enter s24000.

RRF version 3.5.4

Wifi Server 2.2.0

DWC 3.5.4I've got a jumper wire in between DCM and FOR on the VFD

Out6_buff/VFD goes to pulse input +

and VFD GND goes to pulse input -

This is the one I'm using link text; Configuration file for Duet WiFi (firmware version 3.4.6) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.4.6 on Wed Oct 10 2023 (Central Standard Time) ; General preferences M552 S1 ; enable wifi G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"CNC" ; set printer name M453 ; configure CNC mode ; Kinematics M669 K0 ; configure Cartesian kinematics ; Drives M569 P0.0 S0 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M584 X0 Y1 Z2 ; set drive mapping M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M92 X800.00 Y800.00 Z400.00 ; set steps per mm M566 X500.00 Y500.00 Z200.00 ; set maximum instantaneous speed changes (mm/min) M203 X1500.00 Y1500.00 Z2000.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1500.00 ; set accelerations (mm/s^2) M906 X1800 Y1800 Z1700 I10 ; set motor currents (mA) and motor idle factor in per cent M84 S100 ; Set idle timeout M204 P1500 T3000 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X316 Y200 Z130 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!0.io3.in" ; configure active-high endstop for low end on X via pin M574 Y1 S1 P"0.io5.in" ; configure active-high endstop for low end on Y via pin M574 Z2 S1 P"!0.io6.in" ; configure active-high endstop for high end on Z via pin ; Fans M950 F0 C"0.out5" Q200 ; create fan 0 on pin out9 and set its frequency M106 P0 C"Board Fan1" ; set fan 0 value. Thermostatic control is turned off ; Spindle Control M950 R0 C"0.out6" Q70 L6000:24000 ; configure spindle #0 M950 P1 C"0.out3" Q500 M42 P1 S0 M950 P2 C"0.out4" Q500 M42 P2 S0 ; Tools M563 R0 P0 S"Spindle" ; create tool #0 M453 M568 P0 F0 ; set initial tool #0 active and standby temperatures to 0C G10 P0 X0 Y0 U0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Mist Control ;M950 F0 C"0.out6" Q20000 ; create fan 0 on pin out9 and set its frequency ;M106 P0 C"Mist Control" S0 L0.15 X0.85 H-1 ; set fan 0 value. Thermostatic control is turned off ; Miscellaneous M564 S0 H0 ;Allow movement without homing (without axis maxima) ;T0 ; select first tool M575 P1 S1 B57600 ; Custom settings are not defined -

RE: HY VFD controlled by Duet 3 Miniposted in CNC

@dc42

My VFD is the 110v 2.2kw 80mm spindle purchased from Amazon and is supposedly a clone of this one.Closest thing I could find from HY is this one

Otherwise the only thing I have from the seller is a paper manual.

-

HY VFD controlled by Duet 3 Miniposted in CNC

I have my 110v 2.2kw liquid cooled spindle working. I've got the pump wired to the VFD so when the spindle is running the pump is running. I've been searching the forums for a few days and I can't seem to find anything clear that I need to do for my setup.

I can control the RPM through the dial on the front of the VFD. However I'd like full control through DWC as in being able to use start, stop and change RPMs.

I've seen posts that say since I have a duet 3 mini, using the VFD pins all I have to do is connect:

DCM to GND to ground the VFD and the Duet 3 mini

FOR to out6 on the Duet 3 mini to control RPM

I also have a frequency to voltage converter like this one.

So my question is, what's the correct way to do this so I have full control over the spindle through DWC?

-

Switch to limit move incrementsposted in CNC

I have a duet 3 mini running my cnc controlling DWC with my tablet. I use a digital edge finder to find 0,0 of my workspace. Occasionally while dialing in 0,0 instead of hitting .05, .5 gets hit moving the axis too far.

I'm wondering if there's a way to use a toggle switch connected to one of the open input pins as a trigger that could override the axis movements to make sure it doesn't move over .05mm each time a move button is pressed.

-

Errors with new CNC setupposted in CNC

Setting up my Duet 3 Mini 5+ with RRF 3.5.4, DWC 3.5.4 and Wi-Fi server 2.2.0, no SBC. I'm sure something is wrong with the config but I'm not sure what.

I receive the following error:

M98 P"config.g" Error: exactly one of EFHJPSR must be given Error: unconfigured spindle Error: in file macro line 52: M568: Invalid tool numberI used the configurator to build the config file.

; Configuration file for Duet WiFi (firmware version 3.4.6) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.4.6 on Wed Oct 10 2023 (Central Standard Time) ; General preferences M552 S1 ; enable wifi G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"CNC" ; set printer name ; Kinematics M669 K0 ; configure Cartesian kinematics ; Drives M569 P0.0 S0 ; physical drive 0.0 goes forwards M569 P0.1 S0 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M584 X0 Y1 Z2 ; set drive mapping M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M92 X800.00 Y800.00 Z800.00 ; set steps per mm M566 X300.00 Y300.00 Z300.00 ; set maximum instantaneous speed changes (mm/min) M203 X3000.00 Y3000.00 Z3000.00 ; set maximum speeds (mm/min) M201 X150.00 Y150.00 Z150.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z1200 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X289 Y183 Z56 S0 ; set axis maxima ; Endstops M574 X2 S1 P"0.io5.in" ; configure active-high endstop for low end on X via pin M574 Y1 S1 P"0.io6.in" ; configure active-high endstop for low end on Y via pin M574 Z2 S1 P"!0.io4.in" ; configure active-high endstop for high end on Z via pin ; Heated beds M140 P0 H0 ; configure heated bed #0 ; Spindles M950 C"io1.out+io2.out" Q500 L60:12000 ; configure spindle #0 ; Tools M563 P0 H1 R0 ; create tool #0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C ; Miscellaneous M453 ; configure CNC mode T0 ; select first tool ; Custom settings are not defined