Drastic improvements with BL Touch disabled

-

Guys, I am punch drunk with this. I've been at this all day. Loosened, cleaned everything. Measured everything. Changed out the BL Touch. Replaced the Pom nut on the z axis. Reviewed the Z axis flexible couple, nothing wrong with it. Tightened it up. Used my digital calipers to measured off the x axis 2020 ext to the bed. Flat.

My latest go had me going back and forth between Corner 1- Corner 3 and Corner 2 - Corner 4. To all my measuring they are spot on.

I then just went up and down 5 times on each corner to make sure the grip on the paper didn't change. It didn't. I probed the center of the bed 10 times, certainly well within tolerance.

Leave it as all four corners are repeatable and snug the nozzle well.

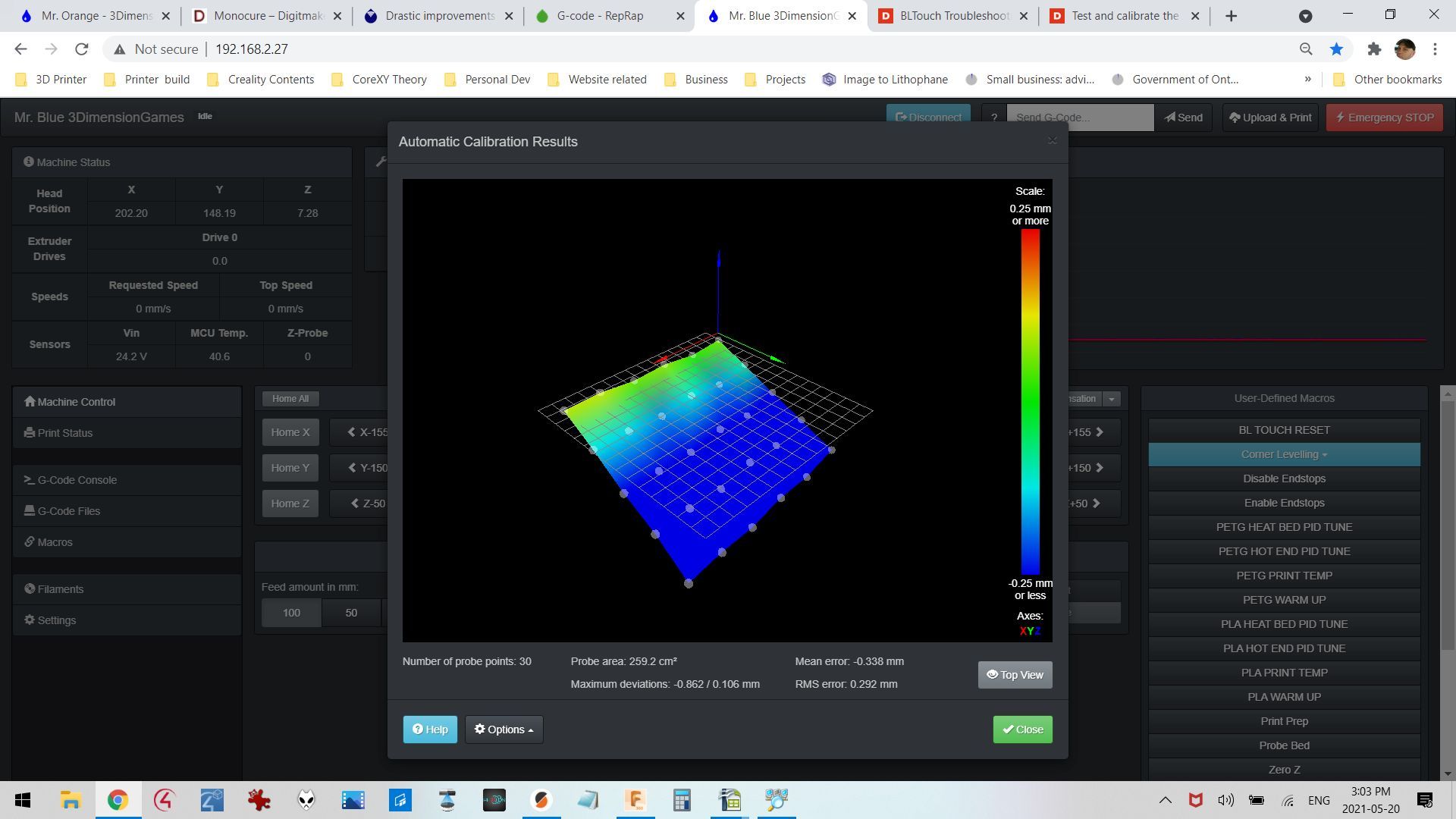

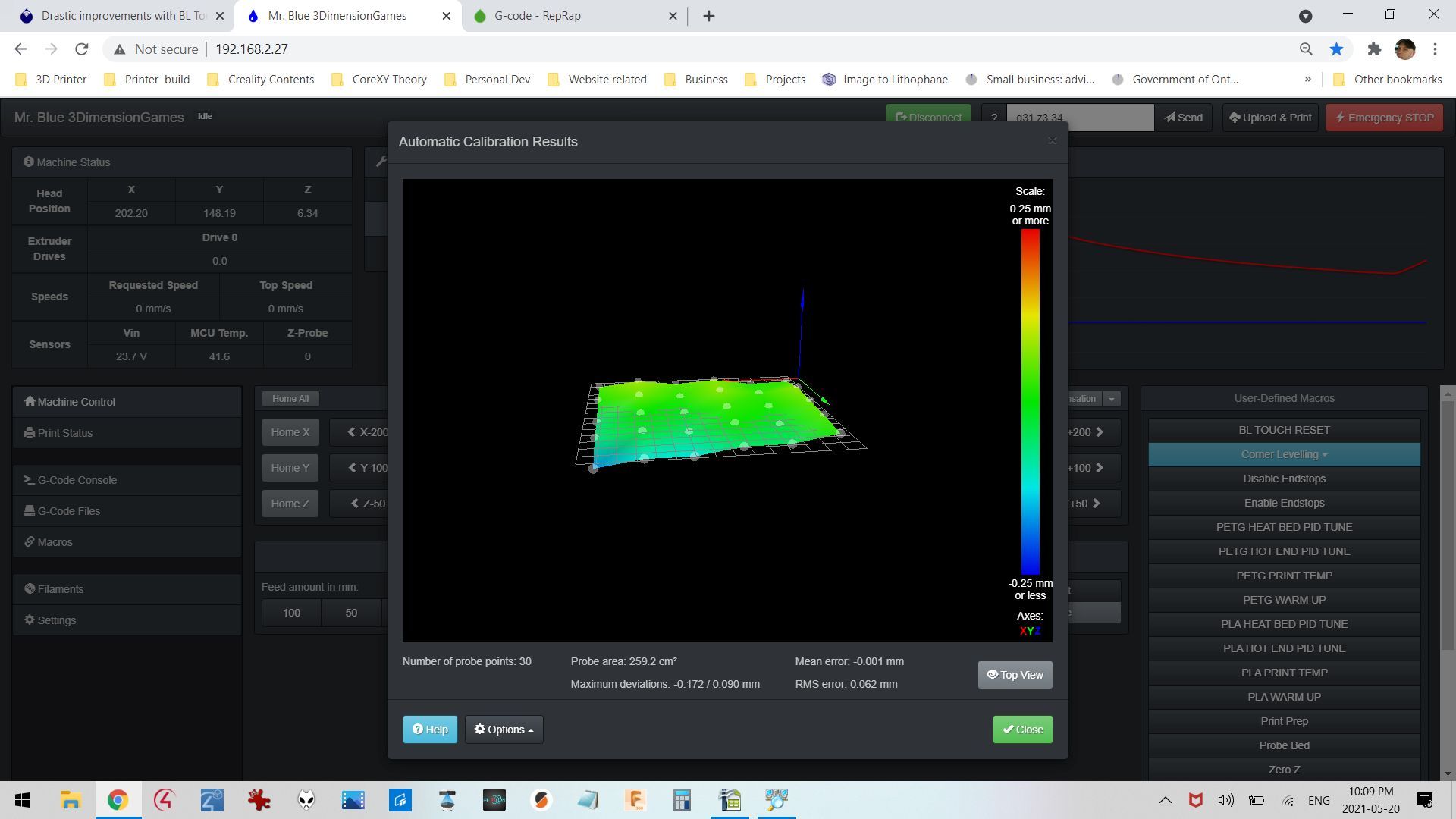

But as soon as I do a mesh level:

Bewilderment is the only work I can describe it.

-

@ryanp said in Drastic improvements with BL Touch disabled:

M350 X16 Y16 Z256 E16 I1 ; configure microstepping with interpolation

Are you really using x256 microstepping on Z?

That's a lot of steps per mm. Can you try switching back to x16 and retesting? Maybe it's a case of missing steps? /shrug? -

@ryanp In your OP on 13th May, you started off by saying (quote)

"So I simply disabled all mesh bed compensation. Just home the hot end, level the corners, and print.

And now I have ridiculously smooth first layers, with no movement in the z axis.

"At that time I said why not leave it at that? Why use mesh compensation if you don't need it?

You had a perfectly good printer producing (quote) "ridiculously smooth first layers" but you've spent a week beating yourself up, stripping everything down, measuring everything, replacing parts, etc etc . Clearly something is amiss with mesh compensation but why spend all that time and effort to fix it when you don't need to use it?

-

@deckingman said in Drastic improvements with BL Touch disabled:

Clearly something is amiss with mesh compensation but why spend all that time and effort to fix it when you don't need to use it?

I dunno about @RyanP but if it were me I wouldn't be able to sleep at night until i figured out why it's not doing what it's supposed to regardless if I "needed" it.

-

@phaedrux said in Drastic improvements with BL Touch disabled:

@deckingman said in Drastic improvements with BL Touch disabled:

Clearly something is amiss with mesh compensation but why spend all that time and effort to fix it when you don't need to use it?

I dunno about @RyanP but if it were me I wouldn't be able to sleep at night until i figured out why it's not doing what it's supposed to regardless if I "needed" it.

On the other hand "if it ain't broke, don't fix it" is an adage that come to mind...............

-

@deckingman @Phaedrux its a bit of both.

Something happened in the last 6 days that caused those perfectly smooth layers to be way out of whack.

I was pleasantly not using mesh leveling. Just homing and leveling my corners. Then boom, all of a sudden that didnt work any longer.

So I have been trying to get it back ever since.

Level the corners....doesn't work.

Ask for a mesh....way out of whach.

I can fake it by using the mesh to make the adjustments to get a flat mesh....but is that a good way to do things? Probably not.

-

@deckingman said in Drastic improvements with BL Touch disabled:

On the other hand "if it ain't broke, don't fix it" is an adage that come to mind...............

but it is broke!

@deckingman said in Drastic improvements with BL Touch disabled:

Clearly something is amiss with mesh compensation

I don't think the issue is necessarily with mesh compensation itself but more likely something with the probe or printer geometry. The tilt is pretty consistent, so I think the probe is accurately showing what it's measuring, but rather than being a problem with the bed it could be the probe mounting or frame being skewed and the trigger height is varying with XY position. Either way, ignoring the problem isn't the same as no problem.

-

The weird part is, nothing has changed on my printer in the last year really. It was printing fine earlier this week.

I will agree that I am not the type of person that lets problems persist. I like to know the why of things.

So here is how things played out on this machine:

Was printing last week as normal with a mesh. Not perfect, but was printing. But had higher first layer failure rates than I was willing to tolerate.

So I disabled the mesh and when with manual leveling. It worked decently. In the mean time I was reviewing things about the BL Touch and mesh leveling to make sure I hadn't overlooked anything in the past. A refresher.

During the time my printer was constantly going. Not failures, great prints.

Then all of a sudden I was having first layer issues. So I decided to go Mesh again, and "crack the code".

Well, I haven't cracked the code yet.

I just ran G32 three times in a row, adjusting the bed after each. I'll post a picture of a print that I ran for the first 2 layers. Clearly their is something wrong.

-

Can you do the G92 Z0 / G30 S-1 trigger height measurement test at different locations on the bed to see if the trigger height is varying with XY position?

-

@ryanp To be clear, are you now saying something contrary to your first post which was (quote again)

"So I simply disabled all mesh bed compensation. Just home the hot end, level the corners, and print.

And now I have ridiculously smooth first layers, with no movement in the z axis."So are you now saying that with mesh compensation disabled, your first layers are no longer "ridiculously smooth"?

-

@ryanp said in Drastic improvements with BL Touch disabled:

Looking at this logically, and breaking things down a bit you said

..............................

So I disabled the mesh and when with manual leveling. It worked decently. In the mean time I was reviewing things about the BL Touch and mesh leveling to make sure I hadn't overlooked anything in the past. A refresher.During the time my printer was constantly going. Not failures, great prints.

Then all of a sudden I was having first layer issues. ...................

So in nutshell, without mesh compensation things were going well then suddenly you had first layer issues. Therefore, logic would dictate that there is some sort of mechanical issue or hot end problem or layer adhesion problem which is leading to inconsistency. Mesh compensation will only mirror this inconsistency - it won't fix it.

-

All of this I very much understood. This bed was never like this before this week. It is warpy, but not slanted. What I found at the beginning of the week was that the mesh seemed to over compensate for the warpiness lending to rough first layers.

Removing the mesh certainly helped at the beginning of the week. But something mechanical has obviously happened during the week to lend to this major slant problem.

What I can't wrap my head around is how the nozzle, which is a relatively fixed distance from the BL Touch pin, can be squared up and safely touching in each corner, and then the mesh turn out so slanted.

Sunken center, and warpy dips....fine. But the nozzle safely touches in all four corners and it is not represented as such in the mesh.

-

I have now disassembled the bed platform, turned it over, and re-secured it. removed and rotated the build plate, re-secured it.

Its amazing how much time you can lose on a mechanical issue.

@Phaedrux regarding the G92 Z0 / G30 S-1, I did this earlier today and started an excel spreadsheet to track the issues. I didn't finish it as it was immediately apparent that the bed was sloping downward at the front (Yaxis), just like the mesh shows. X Axis was relatively stable down to 0.015mm.

Still working on things.

-

Its a start.

-

"Drastic improvements with BL Touch disabled"

I should get one for my printer and disable it.

-

Thanks for your input.

-

@ryanp said in Drastic improvements with BL Touch disabled:

What I can't wrap my head around is how the nozzle, which is a relatively fixed distance from the BL Touch pin, can be squared up and safely touching in each corner, and then the mesh turn out so slanted.

The only difference I see is the Z-offset. You align the bed manually with the nozzle touching the bed, but the mesh routine stops around 2.6mm above the bed. You already replaced the Z-nuts, but something (had) happen during the last 2.6mm.

Maybe Z-acceleration is too high? The same value applies for deceleration. That would get worse when you use multiple small moves to lower the nozzle.Another thing I noticed is the 'bellows' like up and down along X-axis of your last heightmap. Why is every other probe point lower or higher?

-

@ryanp asking the silly questions, but was mesh compensation disabled when you did the nozzle height test? I ended going round and round in circles when I first started using auto bed levelling because I had mesh compensation enabled at the same time (so it was trying to level a compensated bed and the two things just fought each other).

-

Hi @RyanP

I have had similar issues with my printer concerning the bed leveling.

Have you tried to mechanically align all axis to the bed?What helped me was the following procedure:

- Check with a digital Bevel box if the frame of printer is leveled (x, Y and Z Frame)

-> If not, get it leveled - Check if the bed is leveled with digital Bevel Box

-> use X & Y Frame as reference (zero bevel box to that reference)

-> Level it out as good as possible - Check X and Y axis are leveled to the bed with a caliper and get this down to 0.1..0.2 mm

-> It might be that axis are out of level to the frame

Funny thing though, even after mechanically aligning my printer I had a weird effect on the height map.

My finding is, that if the height map shows a clear deviation to one side (mostly X-axis) then the mechanical alignment to the bed might be poor. - Check with a digital Bevel box if the frame of printer is leveled (x, Y and Z Frame)

-

Still Working on it

Corner One Probe

4.309 mm

4.307 mm

4.306 mmCorner 2 Probe

3.981 mm

3.983 mm

3.983 mmCorner 3 Probe

3.380 mm

3.388 mm

3.385 mmCorner 4 Probe

3.933 mm

3.929 mm

3.931 mm