Z offset on Inductive sensors

-

@phaedrux Sure:

Config.g

; Configuration file for Duet 3 (firmware version 3) ORIGINAL

; executed by the firmware on start-up

;; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M669 K1 ; select CoreXY mode; Network

; M552 S0 ; disable network only betas; Drives

M569 P0.0 S0 D2 ; physical drive 0.0 goes forwards X

M569 P0.1 S1 D2 ; physical drive 0.1 goes forwards Y Ultimo cambio: de S0 a S1

M569 P0.2 S1 D2 ; physical drive 0.2 goes forwards

M569 P0.3 S1 D2 ; physical drive 0.3 goes reverse

M569 P0.4 S0 D2 ; physical drive 0.4 goes forwards

M569 P0.5 S1 D2 ; physical drive 0.5 goes backwardsM584 X0.0 Y0.1 Z0.2:0.3 E0.4:0.5 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ;configure microstepping with interpolation. Changed Z to 16 from 32M92 X80.16 Y80.16 Z1600 E428.25:428.25 ; set steps per mm changed Z from 3200 to 1600

M566 X1500.00 Y1500.00 Z300.00 E450:450 P0 ; set maximum instantaneous speed changes (mm/min) CAMBIO set policy to 1 instead of CERO CAMBIO jerk de 900 a 1200 para X e Y. Change policy 1 to policy 0

M203 X18000.00 Y18000.00 Z340.00 E2400.00 ; set maximum speeds (mm/min)

M201 X3000 Y3000.00 Z20 E1500.00 ; set accelerations (mm/s^2) CAMBIO < cambie de 1000 a 3000 a testear, extrusor cambio de 500 a 1500

M204 P2000 T3000

M906 X1500 Y1500 Z1200 E900:900 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S300 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X400 Y400 Z406 S0 ; set axis maxima; Endstops latest

M574 X1 S1 P"!io1.in" ; Endstop X Min

M574 Y1 S1 P"!io0.in" ; Endstop Y min

M574 Z2 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M558 P5 C"^!io3.in" H5 F120 T18000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X-7 Y-29 Z0.3 ; set Z probe trigger value offset and trigger height

; M557 X25:310 Y27:312 S57:57 define mesh grid for beta 3

M557 X33:320 Y10:335 S41:25 ; define mesh beta4; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the chamber heater and set PWM limit

M141 H0 ; map chamber to heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M308 S1 P"temp1" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M308 S2 P"temp2" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 2 as thermistor on pin temp2

M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Tools

M563 P0 D0 H1 ;define tool 0

G10 P0 X0 Y0 Z0 ;set tool 0 axis offsets

G10 P0 R0 S0 ;set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H2 ;define tool 1

G10 P1 X-61 Y0 Z-2.05 ;set tool 1 axis offsets

G10 P1 R0 S0 ;set initial tool 1 active and standby temperatures to 0C; Custom settings are not defined

; movments without homing

; M564 H0; Miscellaneous

M207 S6 R0.2 F1800 ;firmware retraction

M83 ; relative extrusion

M950 S0 C"0.out9" ; servo "0" in pin out9

M280 P0 S115 ; move servo for T1 up default position

; M376 H30 cancell mesh levelling at 30 mm

M143 S450 ; set max temp to 450 degrees for T0

M143 H2 S450 ; set max temp to 450 for T1

M950 J0 C"^io8.in" ; Definition of emervengy stop pin

M581 P0 R0 T0 ; Assigment of the emergency stop

M950 P5 C"out3" ; assign gpio port 5 to out3 for buzzer. control with M42 P5 SX range 0 to 1

M671 X0:350 Y175:175 S3 ; set 2 probing points to correct any possible tilted bed

; M591 D1 P1 C"io5.in" S1 ; pin tapa superior stop

M950 J6 C"io5.in" ; define door pin stop

M581 P6 T2 S0 R1 ; set trigger2.g to be excuted if door opened while printing

M950 J7 C"io6.in" ; define top lid pin stop

M581 P7 T3 S0 R1 ; set trigger3.g to be excuted if door opened while printing

M671 X230:0 Y175:175 S5

M501 ; load saved parameters from non-volatile memory

T0 ; select first tool 0HOME ALL:

; homeall.g

; called to home all axes

;

M564 H0

M280 P0 S115

T0 P0

G91

G1 Z5

M564 H1

G90; HOME X/Y

G91 ; relative mode

G1 H1 X-400 F3000 ; coarse home X or Y

G1 H1 Y-400 F3000

G1 X4 Y4 F600 ; move away from the endstops

G1 H1 X-10 F80 ; fine home X

G1 H1 Y-10 F80 ; fine home Y

G90 ; absolute positioning; Z HOMING

; G1 X175 Y175 F5000 go to first bed probe point and home Z for beta3

G1 X135 Y100 F5000 ; production

M400

M913 Z30

G30

M400

M913 Z100HOME Z

; homez.g

; called to home the Z axisM400

M564 H0

M280 P0 S115

T0 P0

G91

G1 Z5

M564 H1

G90G1 X135 Y100 F5000

M400

M913 Z30

G30 ; home Z by probing the bed

M400

M913 Z100BED.G

; generated by RepRapFirmware Configuration Tool v3.1.4 on Wed Aug 19 2020 03:46:47 GMT-0300 (Argentina Standard Time)

M561 ; clear any bed transform

G28 ; home

G30 P0 X10 Y175 Z-99999 ; probe near left leadscrew

G30 P1 X350 Y175 Z-99999 S2 ; probe near right leadscrew and calibrate 2 motorsSTART GCODE OF SLICER

M104 S120

T0

M141 S100

M116 C0

G4 S120

M104 S{first_layer_temperature[0] -100}

M116

G28 X0 Y0

G28 X0 Y0

G28 Z0

G30; Home z again with probe

M400

G29

G4 S5

G29 S1

M141 S{chamber_temperature[0]}

M116

G4 S180

M42 P5 S0.2

G4 S2

M42 P5 S0

G10 S{first_layer_temperature[0]}

M116 -

Hi,

What materials are part of your bed structure?

What is the make and model of the probe?

Thanks.

Frederick

-

Inductive sensors are usually temperature-sensitive. Did you calibrate the sensor trigger height with the bed and hot end at printing temperature?

-

@dc42 Yes, temperature calibrated. Also, while doing the offset calibration, I do it at the printing temperature.

My printing surface is metal, the sensor can detect 2mm away and the sensor it is 1.5 mm ABOVE the tip of the nozzle, so how can it be possible that the reported offset is 0.3? (or actually "cero" because that is what I have to baby step to have a good first layer) -

@tinchus said in Z offset on Inductive sensors:

M913 Z30

Are you maybe missing steps occasionally from reducing the z motor current too much?

-

@phaedrux the current reduction is only for the probing step, then current is retored to 100%

Also, Im using 30% but I hardly can stop the bed using my hand at that power. Both motors have a really strong arm. I did test and Im at risk of loosing steps at 20 %. So it is somehow not probable that im loosing steps at 30%.Still I did te test at 100% and the problem remains.

-

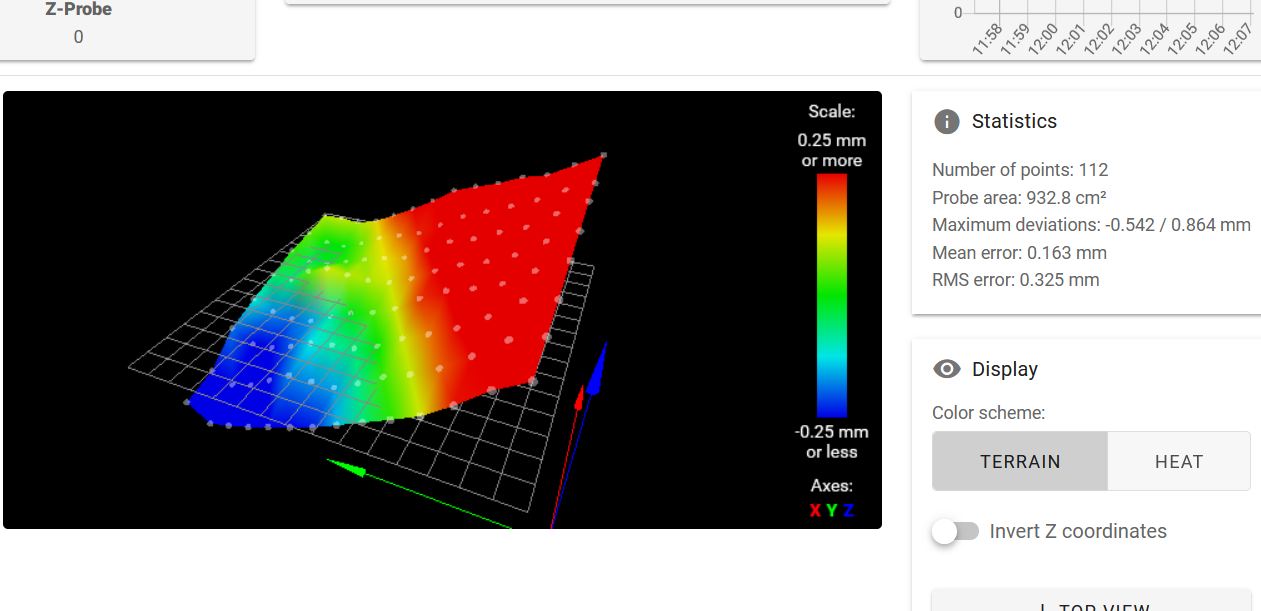

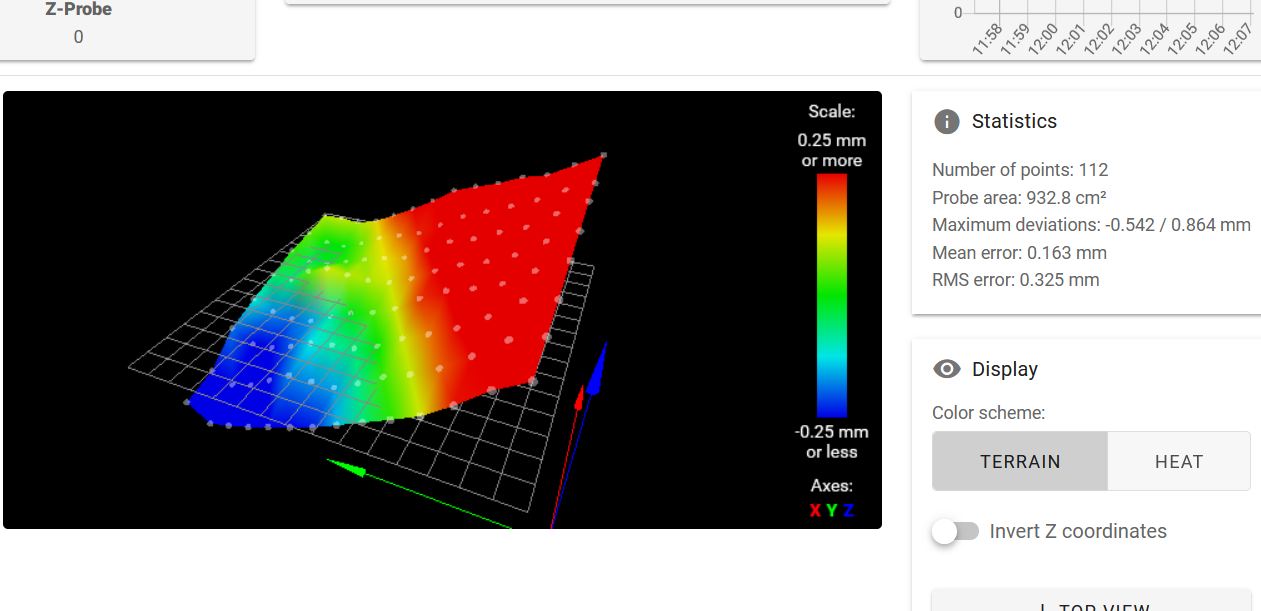

Can you post an image of what your mesh heightmap looks like displayed in DWC?

-

@tinchus said in Z offset on Inductive sensors:

the current reduction is only for the probing step, then current is retored to 100%

Out of curiosity why do you reduce the current?

Thanks.

Frederick

-

@fcwilt because I planned the printer to have eough power to have all the build plate full of print, and since it is a big volumen, theoretically I can have like 15 kgs if I print metal. So Z motors have enough power to move that mass.

BUT, if something goes wrong, the also have the power to destroy my hotenfd and bend the bed if the printhead crash against the bed at full powwer. By reducing to 30% while homing, if something goes wrong, they will start to loose steps before bending my bed. -

@tinchus said in Z offset on Inductive sensors:

So Z motors have enough power to move that mass.BUT, if something goes wrong, the also have the power to destroy my hotenfd and bend the bed

Wow.

What steppers are you using?

Thanks.

Frederick

-

@phaedrux This is just from the oven: heighmap with print chamber at 120 degrees celsius:

-

@tinchus said in Z offset on Inductive sensors:

This is just from the oven: heighmap with print chamber at 120 degrees celsius:

That is not good.

But it does make me feel better about mine.

At what XY point are you setting the Z=0 datum with G30 prior to creating the heightmap?

Thanks.

Frederick

-

That's quite a lot of tilt. On the bright side it looks like the surface itself is mostly flat. Is there anyway you can square the bed and gantry a bit better?

-

@phaedrux What you are looking is the normal deformation an aluinium bed will have under 120 degrees celsius + yes there is some tilt to the front.

-

-

@tinchus said in Z offset on Inductive sensors:

@phaedrux What you are looking is the normal deformation an aluinium bed will have under 120 degrees celsius + yes there is some tilt to the front.

If that is "normal" for your setup I think you need to change the design - that is a lot of tilt - you are talking about 7 to 14 layers of compensation required.

And the nozzle-to-bed relationship will likely have a negative effect on print quality.

-

@fcwilt You are loosing the focus: compensation is working OK. The problem is the Z offset reported, is not realistic.

-

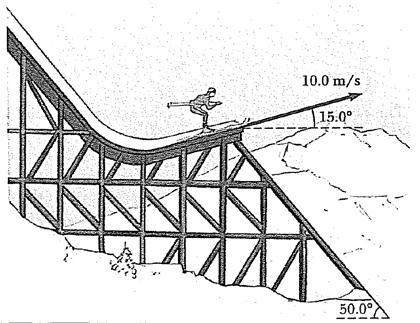

Try this, when measuring your G30 S-1 after touching down your nozzle to the bed, job the probe so that it's over that same point. If there is enough tilt there will be a difference in height between where the nozzle is and the probe is. Just like the triangle formed by the ski jumper leaving the ramp.

-

@tinchus said in Z offset on Inductive sensors:

@fcwilt You are loosing the focus: compensation is working OK. The problem is the Z offset reported, is not realistic.

What do you mean by realistic?

It's accurate so isn't that "real"?

Frederick