Infinite U-axis, but linear motion?

-

Hi gents,

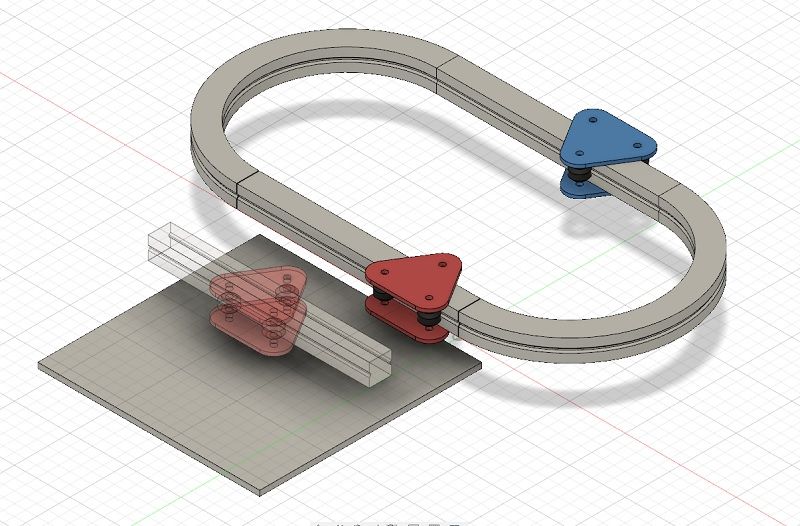

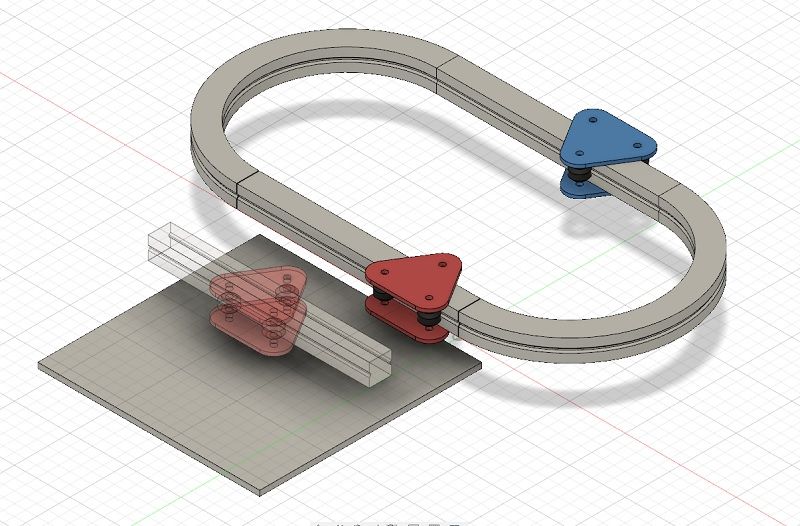

I've made a draft of an infinite U-axis which acts as parking lot for (feltpen) tools.

As you see, the cross beam, which is part of the 'MerryGoRound' is straight and needs to be treated as linear.

The wiring of the tools requires a back and forth tool selection. That's why the whole oval needs to be seen as infinite IMHO.

I can't figure out a way to define the U-axis.

-

This concept is either so far off reality, that noone has an answer or it's so simple, that noone bothers to answer.

Nevertheless, I got my N20-encoder motors now and will build the carriers. Let's see, if I figure out which assumption is true... -

Treat it as a normal linear axis with a fixed length (if you unfold the ellipse, you will get a line of a certain length), and home it at a certain point on the axis.

-

@o_lampe said in Infinite U-axis, but linear motion?:

Hi gents,

I've made a draft of an infinite U-axis which acts as parking lot for (feltpen) tools.

As you see, the cross beam, which is part of the 'MerryGoRound' is straight and needs to be treated as linear.

The wiring of the tools requires a back and forth tool selection. That's why the whole oval needs to be seen as infinite IMHO.

I can't figure out a way to define the U-axis.

Couldn't you just treat it as a rotary axis and have each tool as a predetermined "angle"?

e.g. 10 tools evenly spaced at 36.5 Deg spacing. You'd still have a steps per distance relationship but the circumference of the virtual circle of the path would be the path length of you elipse...

-

There are a couple of problem with an infinite axis:

- When the axis coordinate gets large, precision will suffer. Axis coordinates are store in floating point format, which offers about 6 to 9 decimal digits of precision. So when the coordinate reaches one million mm (1km), the resolution may not be much better than 1mm.

- The axis position has to be converted to a microstep position. Microstep positions are stored in 32-bit signed integer format. So strange things will happen when you go beyond about +/- 2 billion microsteps. With 100 microsteps/mm, this will be at coordinates beyond about +/- 20km.

You could avoid these issues if at certain times (e.g. when changing pen holders) you check whether the axis coordinate has gone outside a certain range, and if so use G92 to reset it to an equivalent coordinate inside that range.

-

@dc42 said in Infinite U-axis, but linear motion?:

There are a couple of problem with an infinite axis:

- When the axis coordinate gets large, precision will suffer. Axis coordinates are store in floating point format, which offers about 6 to 9 decimal digits of precision. So when the coordinate reaches one million mm (1km), the resolution may not be much better than 1mm.

- The axis position has to be converted to a microstep position. Microstep positions are stored in 32-bit signed integer format. So strange things will happen when you go beyond about +/- 2 billion microsteps. With 100 microsteps/mm, this will be at coordinates beyond about +/- 20km.

You could avoid these issues if at certain times (e.g. when changing pen holders) you check whether the axis coordinate has gone outside a certain range, and if so use G92 to reset it to an equivalent coordinate inside that range.

Is this an issue for a polar printer bed axis, or have you included some tricks in the kinematics?

I routinely print in continuous spiral mode so can click up about 3000 rotations for a full size print at 0.4 mm layer height, I think that works out at 5km perimeter for a max size print on the bed. But that's circumferential not the interpreted X Y which never exceeds +-300mm.

Many of my prints actually oscillate so never go outside of a single rotation.

Also as long as this is just an oscillating tool changer carousel I'm guessing it'll never be outside of the length of the elipse perimeter.

-

@whosrdaddy said in Infinite U-axis, but linear motion?:

Treat it as a normal linear axis with a fixed length (if you unfold the ellipse, you will get a line of a certain length), and home it at a certain point on the axis.

If I do that, I'd have to define it longer than it actually is to allow the tools to enter the 'straight' from both sides. I'd then have to home it with an extra endstop, since it arrives at the 'real' 0,0 from the wrong side.

It's worth a try, just have to figure out, which endstop-switch allows pass-through? Optical perhaps... -

@o_lampe optical would work or a well placed mechanical switch with a roller

-

@dc42 said in Infinite U-axis, but linear motion?:

There are a couple of problem with an infinite axis:

I don't plan to let the tools run a marathon in the same direction, but as I wrote above the tools will arrive and leave the straight from both sides. That's the infinite part I couldn't solve as that usually means, it's a rotary axis where a natural transition happens. ( >100rad = 0rad)

-

@jay_s_uk

Yes, rollers are plenty.Maybe I can use the min-endstop from both directions, when I use the single v-roller to trigger?

Sure not, the trigger point would have to be at the tangent of the roller, which is too unreliable.