How to PID tune dual heater cartridges wired in parallel?

-

Thanks for the quick response

Are they wired in parallel

Yes, all 4 leads attached to only Heater 2's + and - terminals. I am sure it's wired right.

They do seem to function as intended, they just overshoot the target temp by too much and my edits to the values in M307 don't seem to have any effect.

I don't think this is a firmware issue so much as likely user error but I will definitely consider updating the firmware.

For now, I will adjust M570 for 35 degree excursion so I can at least start running some test prints with this setup.

-

maybe try M303 H2 P0.5 S220

-

@hackinistrator said in How to PID tune dual heater cartridges wired in parallel?:

maybe try M303 H2 P0.5 S220

That seems to help, this time the overshoot was only 13.3 degrees.

Warning: Auto tune of heater 2 failed due to bad curve fit (G=1505.2, tc=605.4, td=7.5)

11:14:53 AMAuto tune phase 3, peak temperature was 233.3So I have adjusted config.g to:

M307 H2 A1505.2 C605.4 D7.5 S0.5If I run M303 H2 S220 command without a P parameter, does it default to 1.0 or does it use the values saved in M307 H2?

-

@Duetfan223 your heater has simply too much power

try m303 h2 p0.3 s220i think default is 1

-

@hackinistrator ok, I tried with M303 H2 P0.3 S220. Took another minute to heat up but it was even more accurate this time, and did not fail.

M307 H2 Heater 2 model: gain 863.9, time constant 606.6, dead time 7.7, max PWM 0.30, calibration voltage 0.0, mode PID, inverted no, frequency default Computed PID parameters for setpoint change: P16.3, I0.239, D87.7 Computed PID parameters for load change: P16.3 Warning: Heater 2 appears to be over-powered. If left on at full power, its temperature is predicted to reach 888C. Auto tune heater 2 completed in 748 sec Use M307 H2 to see the result, or M500 to save the result in config-override.g Auto tune phase 3, peak temperature was 228.4 Auto tune phase 2, heater off Auto tune phase 1, heater on M303 H2 P0.3 S220 Auto tuning heater 2 using target temperature 220.0°C and PWM 0.30 - do not leave printer unattendedSo, I will set heater 2 in config.g to read:

M307 H2 A863.9 C606.6 D7.7 S0.3I should be able to print now.

Thank you!

-

@Duetfan223 i'm glad that it works , but honestly i don't think that its the right solution .You don't really need that second heater .

-

The reason for the "bad curve fit" message is that the measured gain is so high, because of the very high heater power. The maximum gain (M307 'A' parameter) allowed is the higher of 1500 and (500 + M143 limit).

So your original tuning results were well above the limit:

M307 H2 A3249.8 C542.5 D6.8Your second was within a whisker of being OK:

M307 H2 A1505.2 C605.4 D7.5 S0.5Had you reduced A to 1500, you would have avoided the "bad curve fit" message.

-

@dc42 @hackinistrator said in How to PID tune dual heater cartridges wired in parallel?:

@Duetfan223 i'm glad that it works , but honestly i don't think that its the right solution .You don't really need that second heater .

I have been running a 24v 50 watt cartridge heater on the regular E3D Volcano and can't seem to heat the plastic as fast as I'd like. It's likely a pitfall of using 3mm filament. The SuperVolcano seemed like the logical next step but the standard 24v 80 watt heaters are out of stock. They're nearly 48mm long and I assumed part of the "magic" was having heating elements the whole length of the heater block.

So that's why I decided to go with two 50 watt heaters for now, and I'll buy the 24v 80 watt whenever that becomes available. I had figured I'd set these 50 watt cartridges to S0.8 PWM for "80" watts but I guess it doesn't really work that way?

I still have a lot of 3mm filament I'd like to use up before switching over to 1.75mm. I'd imagine the smaller filament will solve a lot of the problems I've been having with the filament being unevenly heated at higher print speeds.

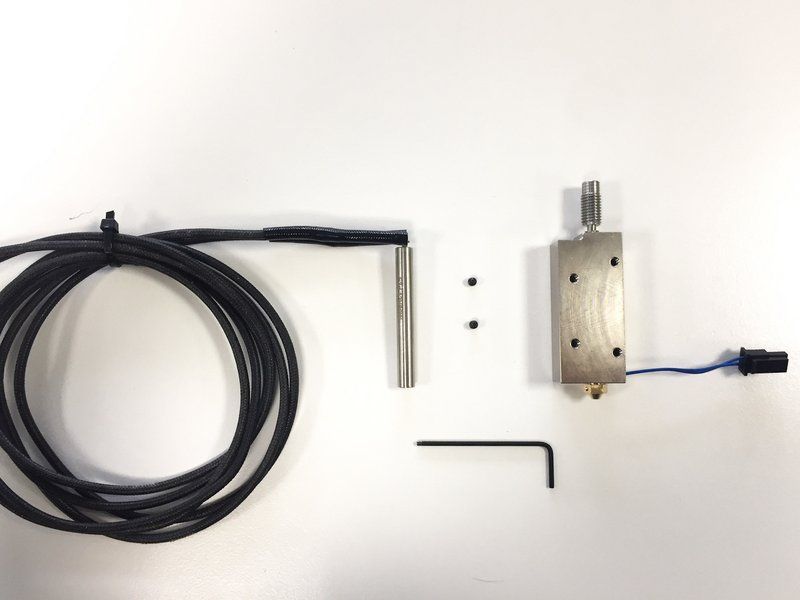

SuperVolcano block & cartridge for reference

2.85mm "bargain basement" PLA, 1650 mm/min at 230 temperature. Notice the "pulsed" affect the filament has on the far side of this print? Is that the heater switching on/off for PID? I updated the firmware and I'll run Auto Tune a few more times. Takes FOREVER to cool down with that sock on there... but that's a good thing, right?

-

Is that a direct drive extruder? If so a geared extruder would help get some torque and smoothness to improve the flow.

-

@Phaedrux Yes it's direct, I'll look into gear extruders