Probe stopped triggering, 4 flashes.

-

When used with a Duet WiFi/Ethernet, the IR sensor is normally used in analog mode. Use P1 in your M558 command,P500 in your G31 command, and expect 4 flashes at power up. That's exactly what I see in your config.g file; but check that your config-override.g file doesn't set a different G31 P parameter.

If you want to use it in digital mode, then in the M558 command you must use P5 and enable the pullup resistor:

M558 P5 C"^zprobe.in" H5 F600 T9000 A4 S0.15

Then expect 2 flashes at power up.

I suggest you run through the commissioning tests, to see whether in analog mode you get the expected readings of about 0, 465 and 535. It may be that the output wire has become disconnected.

-

Well, I've checked the physical connection, and it seems ok. I only get zero from the output, plus I get no LED indicator when I place a light colour object under the sensor.

So the 4 flashes is normal. I only quickly skimmed the documentation when it failed, so I didn't realize that I was reading for digital mode (Which isn't really what I want anyway.)

config-override.g is a blank file. Also, I changed the M558 command to P0 so that I could get some printing done, and that took, so nothing else is setting the probe type.

Anyway, I'll re-check the output wire, though with no LED reaction I don't think that's the case.

-

@SupraGuy said in Probe stopped triggering, 4 flashes.:

Well, I've checked the physical connection, and it seems ok. I only get zero from the output, plus I get no LED indicator when I place a light colour object under the sensor.

That indicates a failure of the optical system. Are the two IR diodes and the phototransistor still in place? Sometimes they get knocked off if the sensor collides with something.

-

Well, that's the answer. I didn't think that the sensor hit anything during that print. Chances are that the LED is buried somewhere in the infill of the part on the printer, since it's nowhere around the printer as far as I can see. I was printing 5 parts with a total of 74mm height and low infill, so if it fell off during printing, it could have fallen right in and I'd never notice.I'm not very confident with SMD soldering. I do lots of PCBs with through-hole though. I guess I need to get used to it. Through hole components are getting harder to find.

-

If you have a thin tip for your iron it's not too hard. Flux is your friend.

-

Well, I ordered some SMD IR LEDs using the part number from the schematic. I've been looking at SMD soldering techniques. Generally it seems to be the same, but more careful, except if using a heat gun. I'm thinking of getting a heat gun too.

In the meantime, I stole the IR board off of my old printer (Which is actually a newer IR board, as it happens.) Neither one seems to have anything soldered for C1, and the board works perfectly, so I assume that's normal. I guess the solder blobs with the air gap are adequate for the very small value capacitor.

Hopefully I can resurrect this board, because the "local" supplier is out of stock.

-

And... In true DIYer fashion, I'll be buying a new heat gun, syringe of solder paste, and another of flux, the SMD IR LED.

So I'm going to fix a $40 board with an $0.87 part.. And $115 in tool and supplies purchases. I've almost talked myself into a somewhat more expensive heat gun, too. Well, we'll have to see how it goes with this one. It's not the cheapest, but it's far from the most expensive one.

My concern is partly getting the LED in place at the correct angle. I'm also a bit concerned that maybe I should replace both in order to ensure that they completely match, but I think wht will happen is that the trigger height will vary some. As long as the nozzle is still above the build surface and it's consistent, I'll be okay with it though.

-

@SupraGuy said in Probe stopped triggering, 4 flashes.:

Neither one seems to have anything soldered for C1, and the board works perfectly, so I assume that's normal.

I confirm, that is normal. I determined that C1 is not needed because the phototransistor has adequate capacitance to suppress high frequency interference.

Replacing just one IR LED will probably work, but if it leads to a trigger height that is too low or too high, replace the other one too. The trigger height range we accept during testing is 2.5 to 3.5mm between the edge of the board and the bed, when using a clean 3mm thick glass bed with black paper underneath.

-

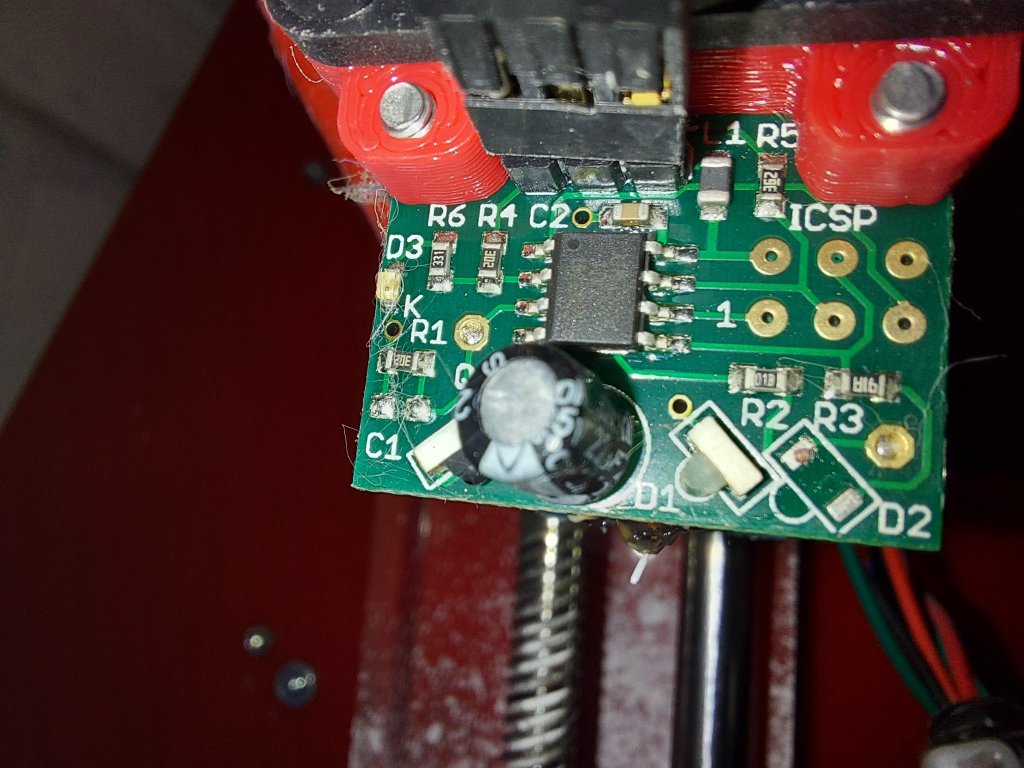

May I present: my first ever successful SMD solder job.I just tested the board, and it triggers properly. I haven't measured trigger distance, but it looks appropriate. Certainly within usable tolerances.

-

Nice work. The sense of accomplishment is well worth the cost of the tools.