Preview version of CNC optimized DWC.

-

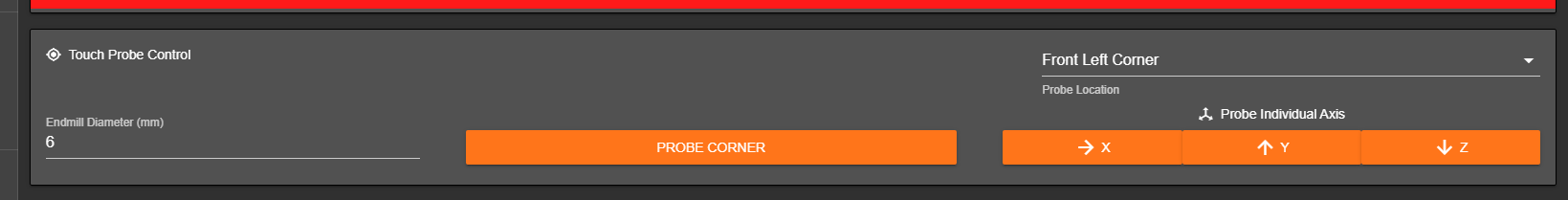

I'm running the Workbee CNC fork on my router. Does this new experimental version of DWC support work edge finding like the Workbee Web Control? Yes, I know I can achieve the same with macros but the way that Workbee does it is very convenient with a single button to press and a box where you input your tool diameter.

-

@rilot I have not used the Workbee CNC ui so I am not sure if it is a macro being fired or a custom wizard they made. I can certainly look into it.

-

@Sindarius The work edge finding in the Workbee panel is a set of boxes you can fill in that automatically generate and then fire macros based on user input. It's very reliable and easy to trigger / configure. If this new version of DWC could do that then I would switch in a heartbeat as there are many functions of the newer Duet firmware I'd like to use but cannot due to needing the older 2.x based version to support the Workbee WC.

-

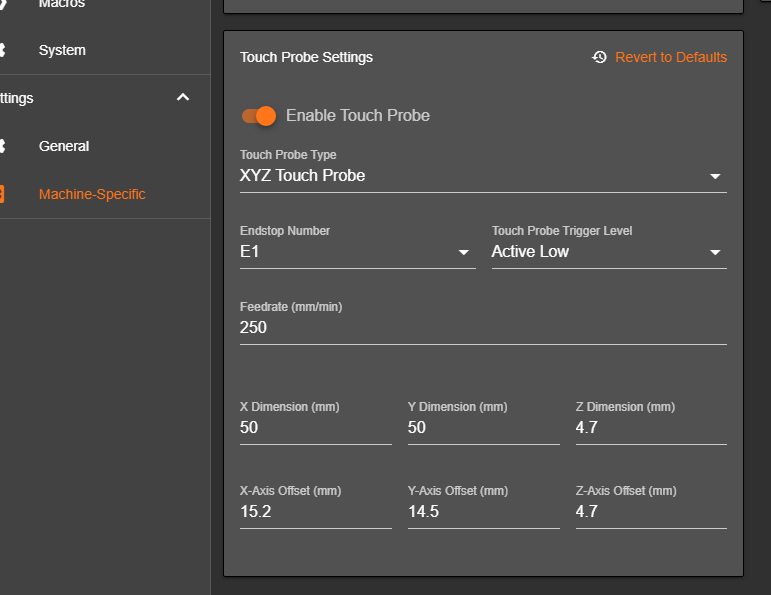

@rilot I pulled down the Workbee Control and took a look at it. It looks like they are generating a probe.g macro on the fly based off those settings when you click probe corner. Since not everyone uses an xyz touch probe I may look into making something like this a plugin. I'll start looking at the gcode to see what needs to be done to generate the macros. The one item that popped out in one of the macros it generated was that it uses P999 for creating a tool and I believe from reading the new limit is 49. Didn't dig too much further into other differences.

-

That's great. Thanks for your efforts with this.

-

Hey @Sindarius, great work!

We have been looking for a way to clean up the interface for our concrete printers for a while now!However, we still have an extruder axis that we need to control, do you think it will be possible to activate the CNC DWC with the nice work coordinate system handler and the big DRO also in FFF mode? (Or also show E axes in the jog button overview?)

Thanks a lot!

-

@too the problem is that the cnc specific pages have had things like the extruder removed since they aren’t needed in cnc applications. It would likely come down to making a plugin that can bring both worlds together in a custom dashboard.

-

@Sindarius Hmm.. I don't know about the inner workings of the DWC, but couldn't it be an option in settings to "show E axis control interface"?

Or would @dc42 have to ass something like this through the firmware? -

@too Axes buttons on the dashboard are driven by the Object Model under Move > Axes. Extruders are in their own area in the Object Model. At some point I could look at bringing in extruders as E# axes but that would not be a focus for me at this moment.

-

I did not manage to install the CNC Webcontrol. The duetwebcontrol_sd.zip can be uploaded under „system“, the files are unzipped, but then nothing happens.

What is my mistake? -

Do you have your machine configured for CNC?

There should be an M453 somewhere in your config to enable CNC mode.

-

@Alpenprinter you need to put M453 to activate cnc mode and with that the dwc for cnc will appear!!

-

@Sindarius said in Preview version of CNC optimized DWC.:

M453

You are the best! Looking great!

Could s.o. please post the config.g and the homing files, for a e axis mill, so I have a starting point for configuration?

-

Hi All, hope you're well. I'm getting my head into this and have a couple of [newbie] questions:

- I'm setting up a z-probe but there is no z probe value on display - should I do the the calibration on the classic DWC then switch over to CNC? Same applies for endstop switches I guess.

- The set work Xyz button: does that link to a macro or does is just trigger a G92 command?

Really think this is a great project!

Thanks,

Neil

-

@neilo said in Preview version of CNC optimized DWC.:

Hi All, hope you're well. I'm getting my head into this and have a couple of [newbie] questions:

- I'm setting up a z-probe but there is no z probe value on display - should I do the the calibration on the classic DWC then switch over to CNC? Same applies for endstop switches I guess.

Those are items that will be addressed in a future version of the DWC-CNC ui.

- The set work Xyz button: does that link to a macro or does is just trigger a G92 command?

It is issuing a G10 L20 command to set the WCS.

My understanding and someone please correct me if I am wrong G92 changes all of the WCS so I avoided it in this case.

Really think this is a great project!

Thanks,

Neil -

G92 does not affect WCS offsets.

-

Awesome thanks both!

-

I’ve been using the preview version for a few jobs and find it a big improvement on the standard DWC for CNC. A couple of thoughts from this experience are:

The X and Y are displayed to 1 decimal place. For me it would be useful to be able to see 2 decimal places, perhaps selectable as a machine specific option, or maybe just on the DRO plug-in screen?

In the jog plug-in screen, buttons to set X,Y and Z to zero in the current work coordinate system would be very useful (as has been mentioned by others).

However, perhaps a better option might be to provide access to macro buttons on the right hand side of either the jog screen or DRO screen and then we can define our own macros to set XY, do Z-probing etc.?

-

@cjm Thank you for the feedback. As mentioned some of these items are on my todo list. The extra decimal places make sense to me as well. I will play with the jog control a bit more. Probably switch the home buttons out and put in a home machine and go to zero set of buttons.

-

Great Job!

My suggestions:

JOG - Add incremental or Continuous movement

JOG - Right click on buttons to adjust movement amountsDRO - Increase frequency of updates and Increase to 2 decimal places

DRO - show conversion under smaller each in inches 0.001"