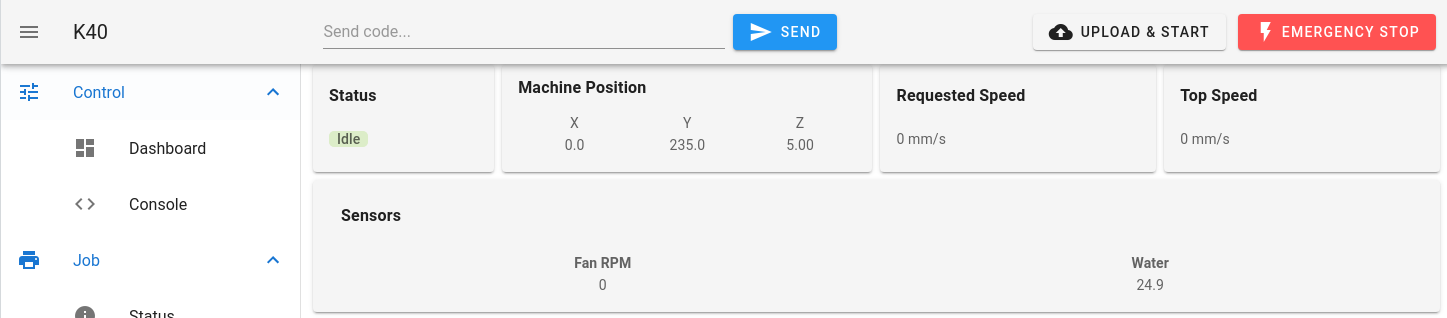

Preview version of CNC optimized DWC.

-

@Sindarius @chrishamm

The current implementation of Go to Workzero moves the spindle through the shortest possible path to the zero position which can have bit breaking or work damaging consequences. For CNC application it is safer to home Z first, then move to X and Y zero before moving down to Z zero.Is it possible to modify the UI so that the Go to Workzero button on the dashboard calls a workzero.g file? Similar to how the Ooznest UI does it. This way we can edit the command and ensure such damage does not happen.

Thanks

-

@chimaeragh I saw the GitHub request and a macro would be the best way to handle it given the configurations people could have.

I thought about making a config where you could set axis order and if it needs to move to min/max first but it would probably end up complicated.

I’ll see what I can get in.

-

@sindarius The problem with using a macro is that it is not part the main dashboard ui. Having a big button that says go to Workzero, but not using it and rather needing to go through a list of macros to perform the same function is counterintuitive and prone to user error.

This is why I am suggesting the button calls a workzero.g file and anyone can edit it to suit their configuration.

Thanks -

@chimaeragh workzero.g would essentially be a macro and the button would just calling that macro.

-

@sindarius Agreed. If the button can be rewritten to call a specific macro (workzero.g) it should be okay.

-

@sindarius

Somewhat ironically, I found the DRO and jog pages easier to read/use whilst the machine position panel was absent because this made the DRO text and jog buttons bigger on my screen…Based on this, perhaps it might be interesting to be able to choose which panels are displayed on each page somewhere in the setup menus or have something like a dwc.config file for users?

-

@cjm can always look at adding a full screen button to the plugin like I did with the 3D Viewer for when you need things larger.

-

@sindarius That sounds a neat and simple solution!

-

@sindarius Thanks for the quick update. Will be testing in the morning

-

@chimaeragh No problem, I don't want anyone breaking bits on my watch

Blown up a couple carbide bits in my day!

Blown up a couple carbide bits in my day! -

@sindarius said in Preview version of CNC optimized DWC.:

@paulg4h let me take a look but I imagine that should not be a problem.

Many thanks again!

With the latest Version 3.3.0-CNC07 the Temperature and Flow are now shown in DWC!

-

@sindarius Tested today and everything works great

. Thanks a lot

. Thanks a lotI had to modify my workzero.g file, I found my Z axis moving up and crashing whenever I used to Go to Zero.

The offending line wasG1 H1 Z1500 F2400before the X and Y axis movement.

I replaced that line with

M98 Phomez.gand it's working OK now.

-

@chimaeragh I need to double check but you may want to try G0 H4 when you go to move to the top of the z axis. Worth a shot at the very least.

-

@sindarius I have tried that, but I seem to lose my current Z zero position so I've commented it out and gone back to calling homez.g which works fine

-

@Sindarius I have just noticed that tool position coordinates do not update in real time, but only after starting a new segment of gcode. Is this intentional or a bug?

-

@chimaeragh The position is how it is reported through the object model. What I normally see is tool position updates when the move starts and machine position updates after a move has completed. It's not a DWC-CNC specific behavior.

-

@sindarius OK. I think it worked differently on RRF2. Curious why it was changed but it's not too much of a problem.

Jogging updates in real time though -

@chimaeragh I'm not sure it was any different in RRF2 though.

In RRF 3.3 you could try decreasing the segment size to make for smaller move lengths. That might let it update more frequently, but I'm not certain. See M669 S and T

-

G91 G1 H3 Z90 F500 G90 G1 X0 Y0 F6000 G1 Z0I set this up on my test CNC machine and it worked fine for a go to zero macro. you can set the Z value greater than you z travel and it should stop when the limit is hit.

-

@sindarius Thanks