Preview version of CNC optimized DWC.

-

@mdhazell In the short term you can probably just open up the zip file and go into the plugin.json file and change it to 3.3. I'll look at updating that plugin as well.

-

Does 3.3.0-rc3 of DWC-CNC support the final 3.3.0 RRF release?

-

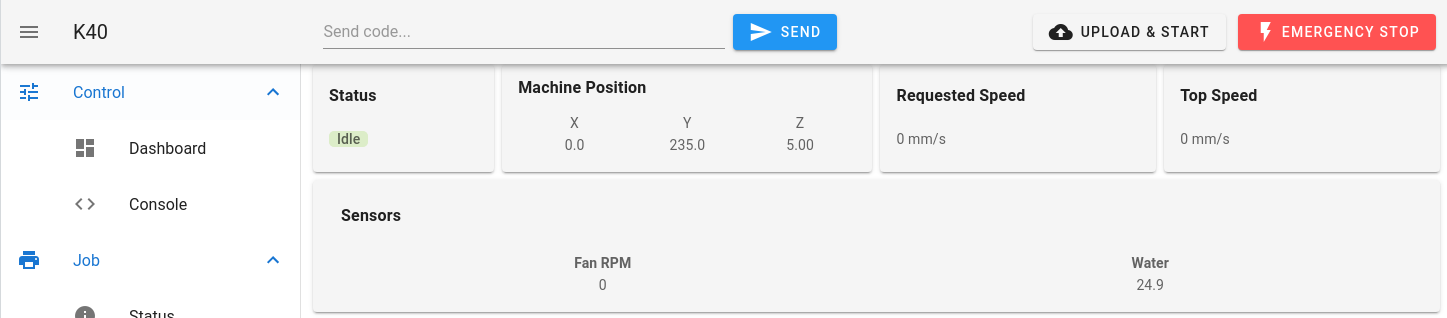

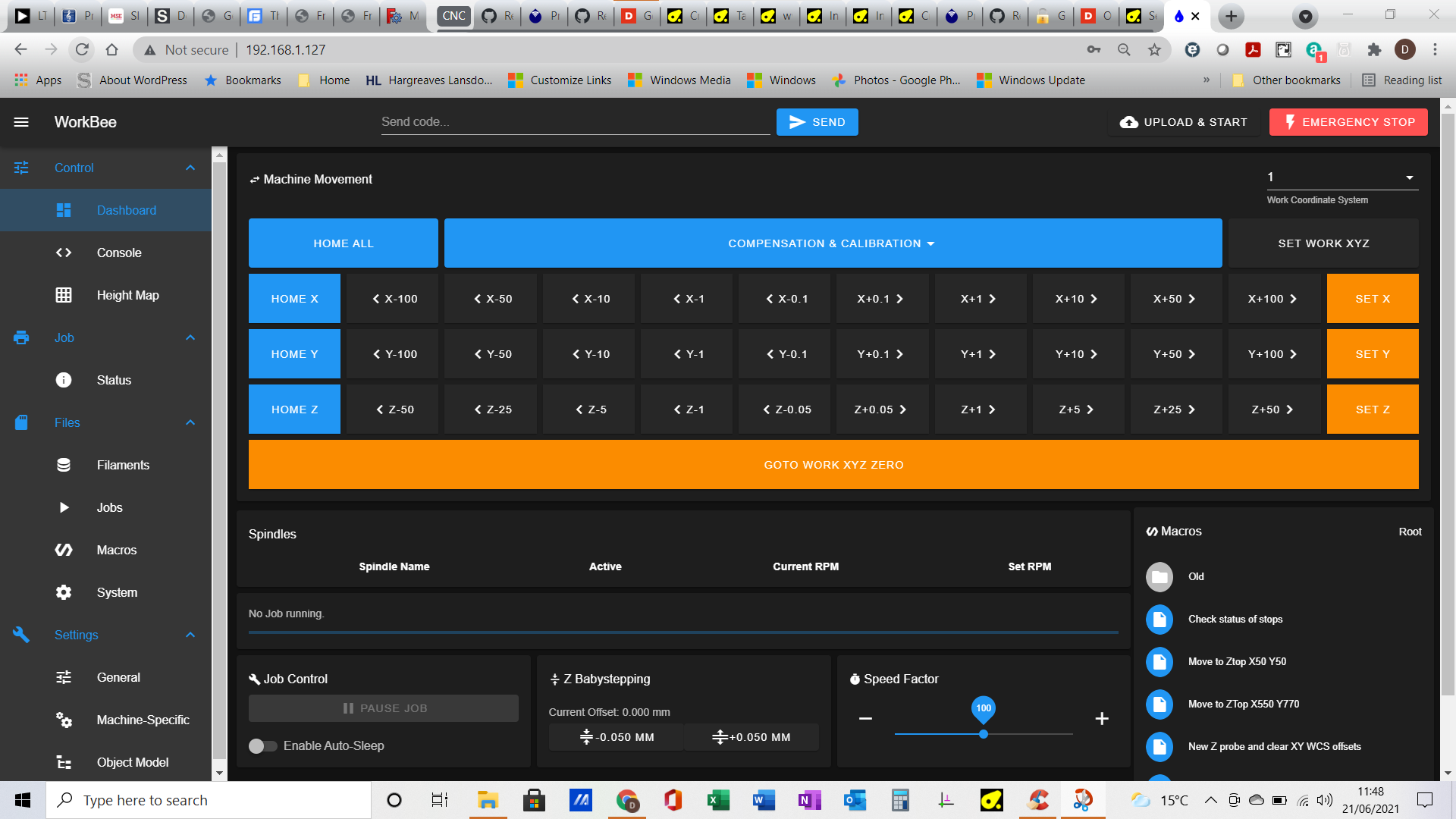

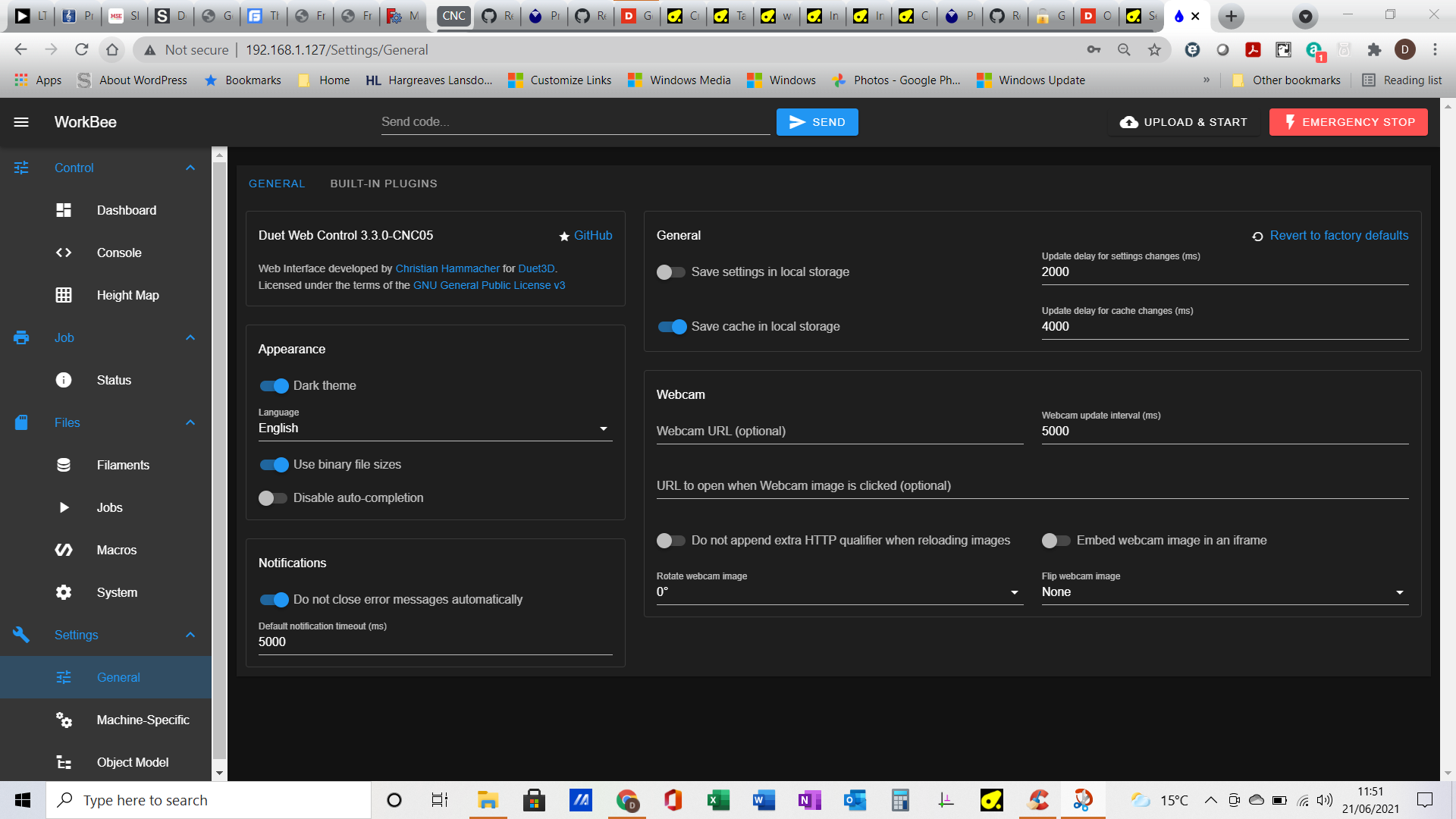

@Sindarius I've just updated to RRF3.3 on my Duet2 WiFi and also updated to your latest DWC CNC 3.3.0 in the hope of getting back the z-probe status but the dashboard no longer shows current axis positions at all so not sure what's going on.

I have attached screenshots of the dashboard and general settings below.

-

@crossbow I have found the issue and am going to have a new release available in a little while. Will edit this post when complete.

Edit:

New version is here https://github.com/Duet3D/DWC-CNC/releases/tag/3.3.0-CNC06 -

@sindarius Thanks a lot !!!

-

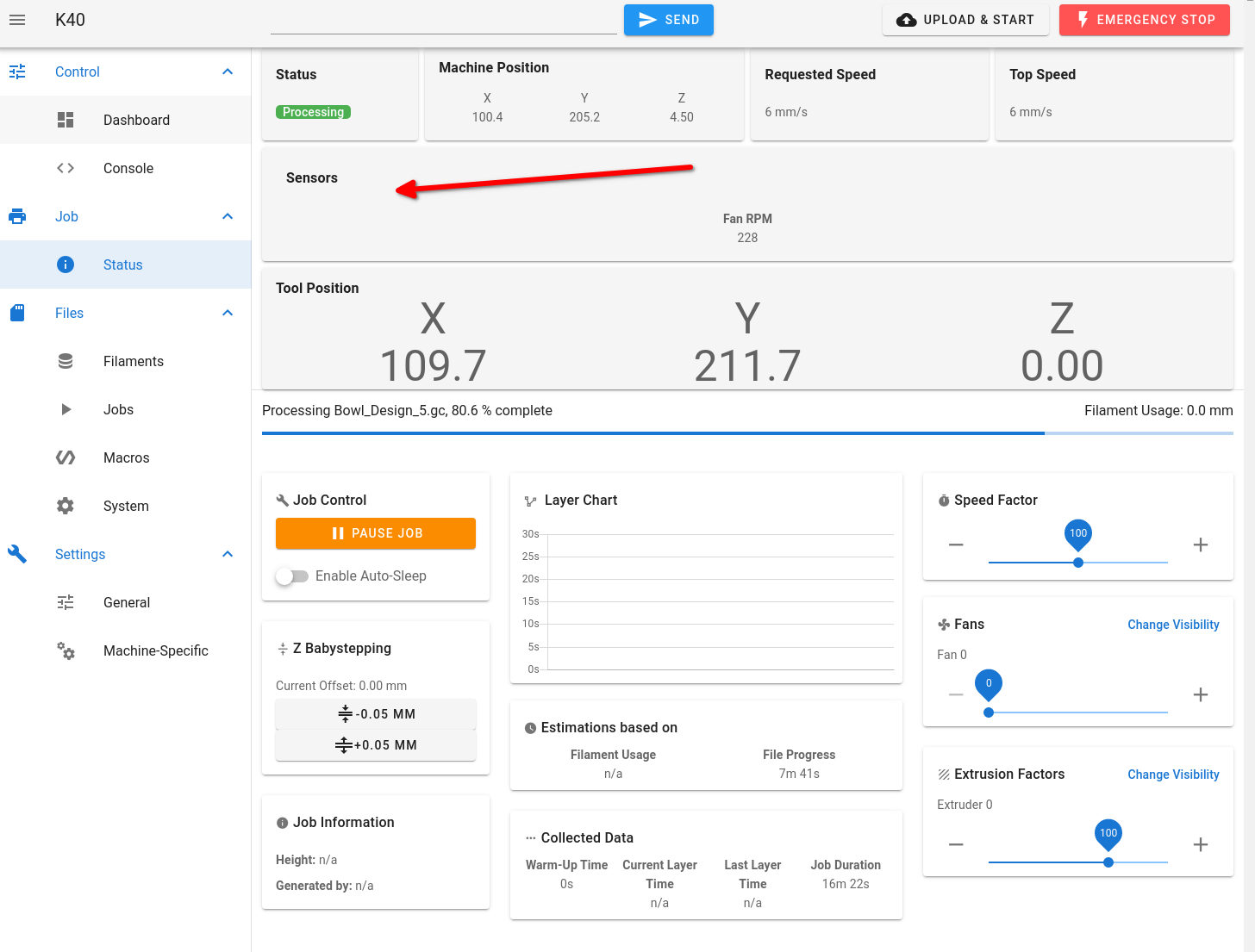

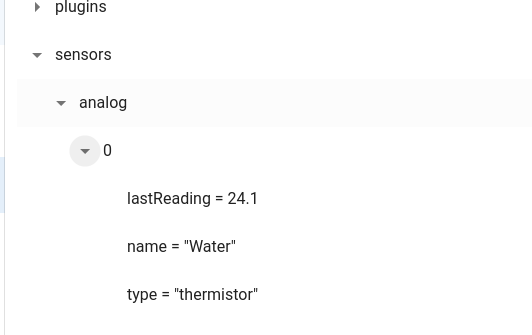

@sindarius is it possible to show in LASER and CNC Mode in the sensors area as marked below also temperature values?

I do have a flow meter which are configured as fan rpm input and a thermistor to get the water flow and temperature.

Maybe it is easy to show all analog sensor values, here are mine in Object browser:

Many thank's for your support!

-

@sindarius thanks, that works brilliantly now

-

@paulg4h let me take a look but I imagine that should not be a problem.

-

@Sindarius Hi, can you also look at your DWC_GamepadJogger_Plugin?

Im trying to install the gamepad plugin, but im getting "Prerequisites Invalid plugin manifest " error. Installed Touchjog pluggin with any problem. -

@Sindarius @chrishamm

The current implementation of Go to Workzero moves the spindle through the shortest possible path to the zero position which can have bit breaking or work damaging consequences. For CNC application it is safer to home Z first, then move to X and Y zero before moving down to Z zero.Is it possible to modify the UI so that the Go to Workzero button on the dashboard calls a workzero.g file? Similar to how the Ooznest UI does it. This way we can edit the command and ensure such damage does not happen.

Thanks

-

@chimaeragh I saw the GitHub request and a macro would be the best way to handle it given the configurations people could have.

I thought about making a config where you could set axis order and if it needs to move to min/max first but it would probably end up complicated.

I’ll see what I can get in.

-

@sindarius The problem with using a macro is that it is not part the main dashboard ui. Having a big button that says go to Workzero, but not using it and rather needing to go through a list of macros to perform the same function is counterintuitive and prone to user error.

This is why I am suggesting the button calls a workzero.g file and anyone can edit it to suit their configuration.

Thanks -

@chimaeragh workzero.g would essentially be a macro and the button would just calling that macro.

-

@sindarius Agreed. If the button can be rewritten to call a specific macro (workzero.g) it should be okay.

-

@sindarius

Somewhat ironically, I found the DRO and jog pages easier to read/use whilst the machine position panel was absent because this made the DRO text and jog buttons bigger on my screen…Based on this, perhaps it might be interesting to be able to choose which panels are displayed on each page somewhere in the setup menus or have something like a dwc.config file for users?

-

@cjm can always look at adding a full screen button to the plugin like I did with the 3D Viewer for when you need things larger.

-

@sindarius That sounds a neat and simple solution!

-

@sindarius Thanks for the quick update. Will be testing in the morning

-

@chimaeragh No problem, I don't want anyone breaking bits on my watch

Blown up a couple carbide bits in my day!

Blown up a couple carbide bits in my day! -

@sindarius said in Preview version of CNC optimized DWC.:

@paulg4h let me take a look but I imagine that should not be a problem.

Many thanks again!

With the latest Version 3.3.0-CNC07 the Temperature and Flow are now shown in DWC!