Smart Effector including toolboard-capabilities?

-

@oliof said in Smart Effector including toolboard-capabilities?:

@dc42 if you ordered the blurolls version: Mine did come with off-spec holes for the axles since the original models are made for FDM tolerances but it's been made with SLS Nylon; re-printing the idler arm was sufficient to make everything fit.

What are you considering to be the idler arm? A picture would help.

I bought one from "sealander" (although they do say it is by blurolls) so we will see what happens in three months time, after it has been half way around the world on the slow boat from China

-

@CaLviNx Sealand and blurolls are one and the same. And you're right, there is no idler arm, on the thingiverse listing it's the Latch.

-

@oliof said in Smart Effector including toolboard-capabilities?:

@CaLviNx Sealand and blurolls are one and the same. And you're right, there is no idler arm, on the thingiverse listing it's the Latch.

Thank you for the update, that was why I asked.

I have an adapter drawn up to allow fitment to the smart effector, I might try to see if I can sneak in a standard sized tool board (LC-1) in there too. -

@oliof said in Smart Effector including toolboard-capabilities?:

@dc42 if you ordered the blurolls version: Mine did come with off-spec holes for the axles since the original models are made for FDM tolerances but it's been made with SLS Nylon; re-printing the idler arm was sufficient to make everything fit.

In what way where the holes off Spec (small or large)?

-

@Dougal1957 the holes are too large (4.25mm diameter rather than 4mm). I printed a replacement latch in ASA and the axles just press fit nicely.

-

@oliof all 3 of mine came spot on both the 3mm hinge pin and 4mm idler shafts fit just fine so maybe they have tweaked there files to suit. All three did have packing issues mind the first came without the drive gears and the last 2 came without the feast couplings but Blurolls have sorted that issue out and I now have 3 fitted to the Jubilee ToolChanger

-

Mine came in this past week with the shaft too small (2.9mm) and the holes on the arm too big (3.1mm)

-

@Dougal1957 good to hear they at least read my feedback (-:

-

Mine came at last. The 4mm idler axle wouldn't fit into the latch at first, I had to ream out the hole at one end of the latch a little and then use a hammer to tap it into the other end. I have one long M3 screw and nut left over - no idea what those are for.

-

I used the new bolt and nut to attach the latch and have a leftover axle (-;

-

@dc42 yeah I to had a longish M3 bolt and nut left over on all 3 of mine but they all did fit together nicely

doug

-

It's clear to me that the Orbiter could not be used with a Smart Effector made to the current dimensions. We would need to increase the rod spacing to at least 80mm in order to accommodate the various parts of the extruder. We are looking into this, however it would make it unsuitable for the smaller delta printers.

-

-

Interesting! However, that reduces the printable height somewhat. What is the printable area of your delta, and how much would you lose if the rod spacing was increased to 80mm?

-

@dc42 said in Smart Effector including toolboard-capabilities?:

Interesting! However, that reduces the printable height somewhat. What is the printable area of your delta, and how much would you lose if the rod spacing was increased to 80mm?

Personaly David I don't think I would lose any build volume at all my bed is 360 Diam I may lose a little bit of Z but not a lot (Our printers are pretty similar apart from mine is a bit wider and upside down and 450 long arms.

So if you want to try it at this size I can easily test one. as I did the first one.

Doug

-

@dc42 said in Smart Effector including toolboard-capabilities?:

Interesting! However, that reduces the printable height somewhat. What is the printable area of your delta, and how much would you lose if the rod spacing was increased to 80mm?

I lost 45mm in print height, and coincidentally without even thinking about it or trying, my print height now exactly matches the print area of 320mm as I was slightly longer on my vertical rails anyway.

-

@dc42 found this too

-

This topic is interesting!

Ordered an Orbiter too. I'll want to use it in my Frankenstein Predator.

Please keep us updated about possible Smart Effector updates - looking forward to this

-

We do plan to produce a combined Smart Effector and tool board, however we need to get another hardware project completed first.

-

@dc42 said in Smart Effector including toolboard-capabilities?:

It's clear to me that the Orbiter could not be used with a Smart Effector made to the current dimensions. We would need to increase the rod spacing to at least 80mm in order to accommodate the various parts of the extruder. We are looking into this, however it would make it unsuitable for the smaller delta printers.

Hi dc42,

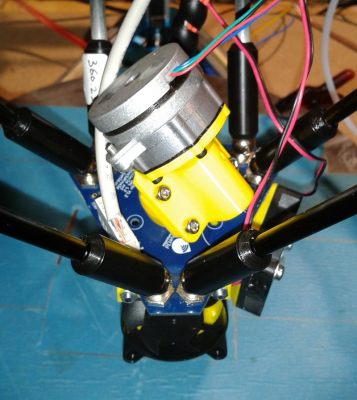

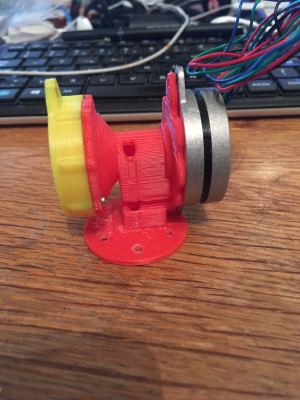

I just stumbled across this thread and wanted to guide you back to 2016 , when we discussed the cycloidal direct drive. (I still have it laying around)

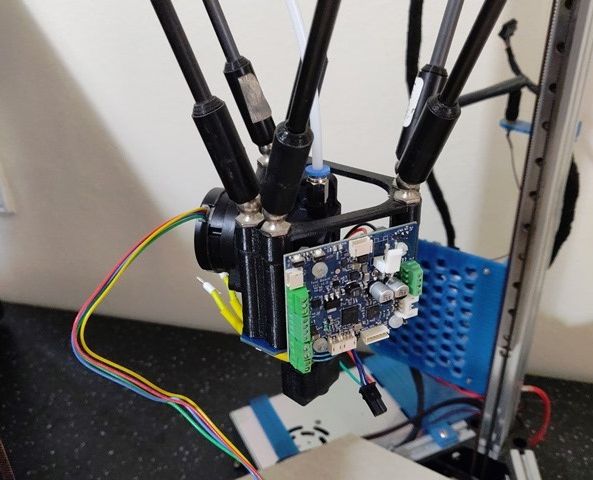

I've made an 45 degree adapter for it, that suited the smart effector pretty well.

Another way to mount it, was the split motor/gearbox idea.

I could try to reuse my motor and design a BMG-drive for the Smart effector?