Tips to mitigate vertical artifacting Duet 2 Wifi

-

@mwolter Thank you! That's an interesting thought. I will setup a test and see what happens.

-

@brotherchris

If you are running them over F623zz then finding a good tooth pulley will be hard.

the only thing that comes close are Gates Powergrip 2GT Idlers, buy they are 5mm ID.

2GT Idlers, buy they are 5mm ID. -

@Veti Yeah, that kind of sucks. I have been looking for alternatives all morning, but 5mm bore is about my only option. I really didn't want to go down that small. I am determined to find some sort of work around.

-

what quality are your F623zz ? for a corexy they should be ABEC-3 or above.

-

i am going to test these myself once they arrive.

https://www.aliexpress.com/item/4000040551804.html

but i dont have high hopes -

@Veti I am actually using F688ZZ. Not sure the grade.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

F688ZZ

closest thing i can find is

https://www.aliexpress.com/item/32961265334.html

but its 6mm bore -

@Veti I am trying 16 tooth idlers like this on my kossel delta, but have bought some 6x2.5x3mm bore bearings, and pressed 3 into each idler. You clamp the idler firmly (not possible with the original 2 bearing idlers), but you need 3mm bore washers that are 4.5mm diameter to do this. Will be interesting to see if they last longer.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@Veti Yeah, that kind of sucks. I have been looking for alternatives all morning, but 5mm bore is about my only option. I really didn't want to go down that small. I am determined to find some sort of work around.

It seems you think 5mm is too small. Why do you think that is so?

Thanks.

Frederick

-

@fcwilt It's not that I think it's too small, I just wanted a little larger hardware on this setup.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

I need to find some toothed pullies that will fit my setup.

I was able to do a few belt twists to run the smooth side of the belt over my flanged bearings. When I tried toothed idlers there was still a lot of ridges. I think the small 16T idlers are just too tight of a bend for the teeth to mesh smoothly. I was able to have the belt twists on the fixed length sections between the motor and the rear idlers.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

It's not that I think it's too small, I just wanted a little larger hardware on this setup.

ok then here you go.

https://www.aliexpress.com/item/32961693003.html

its 8mm bore.

but the diameter is larger than the F688ZZ -

@Phaedrux Run a test with a belt twist now.

-

@Veti Nice find, I am going to grab some for testing.

-

@Phaedrux Still confused, the belt flip didn't change anything.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@Phaedrux Still confused, the belt flip didn't change anything.

Well that's one more thing to cross off the list and leaves stepper artifacts. I wonder if it's related to the exoslide movement? Is there more or less resistance to motion with it?

Were you able to print a test that varied the speed over a range to try and see if there is a speed which doesn't excite the artifacts?

-

What I.D. would you prefer for a toothed idler? Also, what effective O.D. are you aiming for? (to keep the belts aligned)

I agree it's too hard to find the right idlers, but Misumi has a few options I could try and find something for you.

-

@bot Most of the bearing are 8mm ID and 16 OD. I have 2 that are 8mm ID 12mm OD, 1 in each path to help with clearance.

-

@Phaedrux The max speed test is interesting. Started at lower speeds. As it got faster the ringing increased, the artifact stayed the same.

-

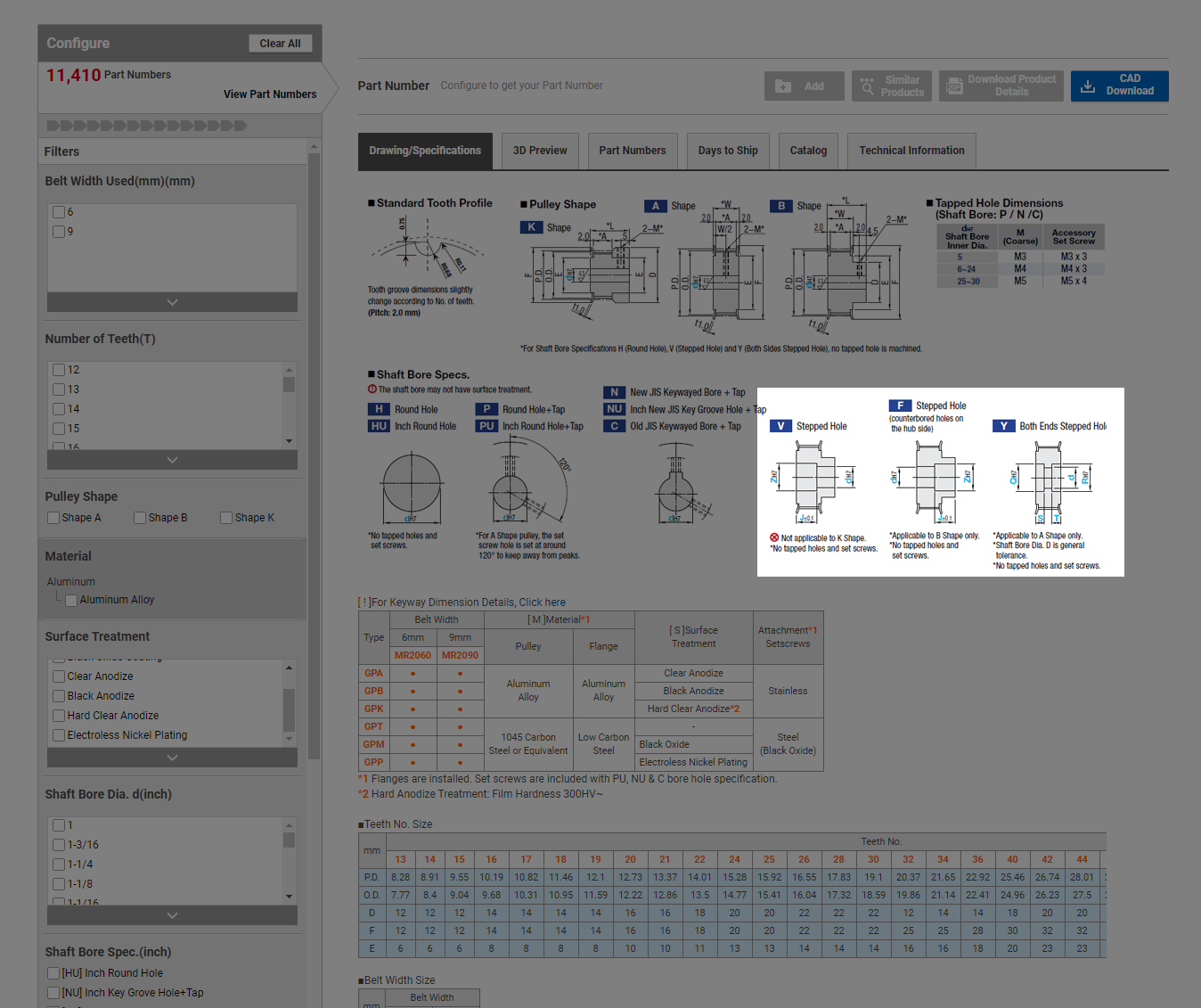

Well, I wasn't able to find any ready-to-go off-the-shelf idlers from Misumi (that are more than 5 or 6 mm), but I've always wanted to try using one of their customizable pulleys for idlers: See info here.

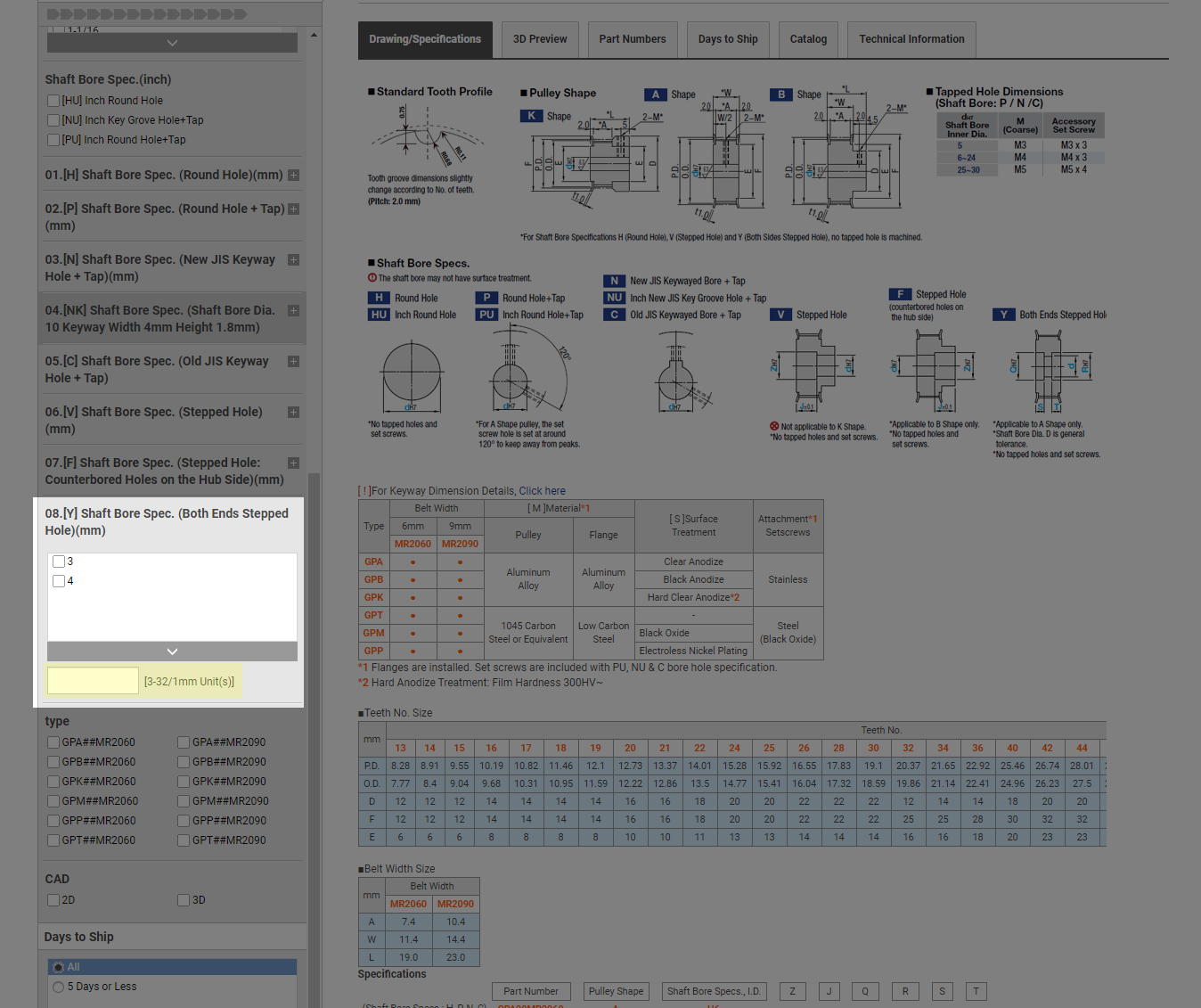

You can choose a wide range of sizes of pulley there, and you can get stepped holes made which should allow for easy placement of bearings. They have a variety of options and you can have the stepped hole sized how you wish. See:

[Edit: this photo is slightly misleading, there are more options to configure to get a full part number. Still playing around with it

]

]