slant lines

-

@matt3o said in slant lines:

I can certainly try with an e3d, but I'm on mosquito now... I hope it's not that with all that I spent for it

Do not mistake mellow nf crazy hotend (that I used in this test) with mosquito, the only similarity between them is visual! Friend is using original with way worse setup than mine without a single issue with PLA and even without cooling

My mellow experience got him scared so he added cooling

My mellow experience got him scared so he added cooling

but it worked even before forced cooling (you just can't go too crazy with retraction as with any all metal) so if you are rocking original mosquito don't worry. Also check out the vent from @smece (my neigbor who introduced me to duet2eth btw) about his mellow https://forum.duet3d.com/topic/14161/mellow-nf-crazy-hotend?_=1582807022109 again, none of those issues are visible on the original mosquito.

but it worked even before forced cooling (you just can't go too crazy with retraction as with any all metal) so if you are rocking original mosquito don't worry. Also check out the vent from @smece (my neigbor who introduced me to duet2eth btw) about his mellow https://forum.duet3d.com/topic/14161/mellow-nf-crazy-hotend?_=1582807022109 again, none of those issues are visible on the original mosquito. -

I recall similar issues with the zesty nimble being solved by changing the lubricant, I only looked into it since I recall some reports of flexible shaft having bad short lifespan on delta machines.

-

@lord-binky said in slant lines:

I recall similar issues with the zesty nimble being solved by changing the lubricant, I only looked into it since I recall some reports of flexible shaft having bad short lifespan on delta machines.

Do not get me started on the issues with zesty

I am using this dual flex3drive for a couple of years. It was designed together with the first flex3drive system, and I never had issues. I used 1.75 and 3.0 hexagon hotends with the dual flex3drive system. I dismantled that and made two single G5 ones as I'm going to use toolchanger for the multimaterial print. No need for complexities of leveling 2 hotends any more. No idea if this slanted lines came from failing flex shaft, mellow or something else. But replaced flex shaft (old thin one, new sturdier one is in post) and the hotend and lines are gone. I did replace also (but before the lines) stepper motor I wanted to use as I put there a 400steps/revolution stepper that had too much inductance so could not rotate fast enough. I'm not lubricating my flex3drive at all

that is probably a mistake too.

that is probably a mistake too. -

@matt3o mhh, gates belt and pulleys should be fine, I use them too. Do you use gates pulleys as idler's. I do, maybe normal bearings could be responsible.

-

@arhi said in slant lines:

No idea if this slanted lines came from failing flex shaft, mellow or something else. But replaced flex shaft (old thin one, new sturdier one is in post) and the hotend and lines are gone

the problem is that I get those even when driving the g5 directly...

@CaiJonas said in slant lines:

Do you use gates pulleys as idler's

yeah sorry, I use gates idlers and pulleys

-

@matt3o said in slant lines:

the problem is that I get those even when driving the g5 directly...

Did you try different flow rates (different speeds, different layer height) that do not change the slanted lines?

I was so worried when I got them, and then they went away, now I fear they will come back if I don't know what exactly caused them.

-

@arhi said in slant lines:

Did you try different flow rates (different speeds, different layer height) that do not change the slanted lines?

yeah the slanted lines change based on speed and layer height, also steps/mm on the extruder.

-

@matt3o, I had once exact same pattern of slanted lines. That was when I was trying the Zesty Nimble (also a flex drive extruder). I ended up switching to a direct drive extruder (BMG + 150g motor + V6 hotend) and am very happy with the results.

YMMV.

-

Having looked at the links to worm gears, I am inclined to think that the slant lines are caused by uneven motion of the gear driven by the worm. In which case, the horizontal period of the lines should correspond to 1 rotation of the worm.

-

I am still convinced your slant lines are from the worm gear.

It is very similar to the z-wobble you can get when using a lead screw, but it acts on extrusion instead of z layer height.

If anything is mounted even very slightly off-angle or out of position you will get periodic small errors.

A long lead screw mounted too poorly will bind up and warn us, the small worm in our case will not. -

@dc42 @bondus how can you guy's explain then that they are gone on my printer and I did not change the worm gear? Exactly the same G5 is on my printer, I replaced the flex shaft (old one broke) and the hotend?

p.s. I'm digging through my plastic trash to find those pieces with slanted lines so I can measure them, I keep all my plastic trash so not an easy task but I'll get back when I do.

-

-

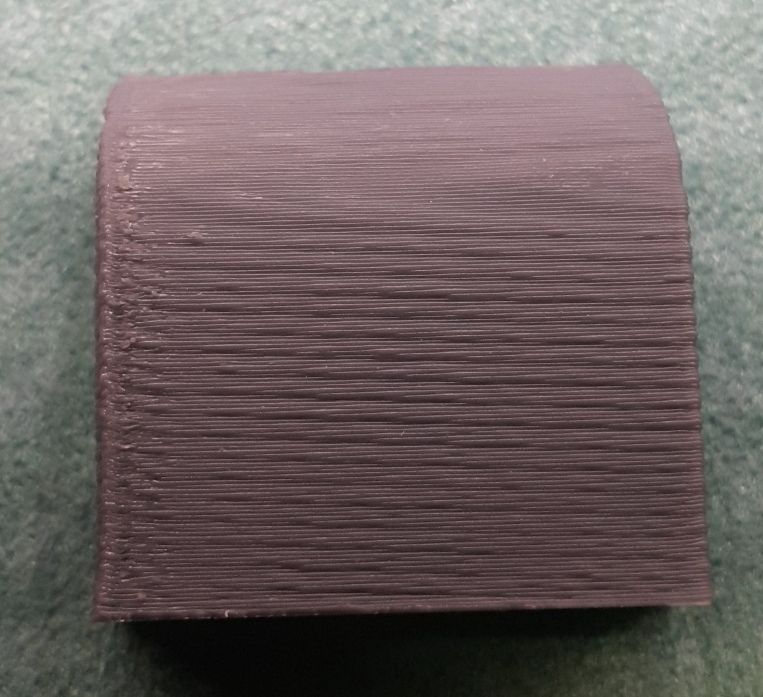

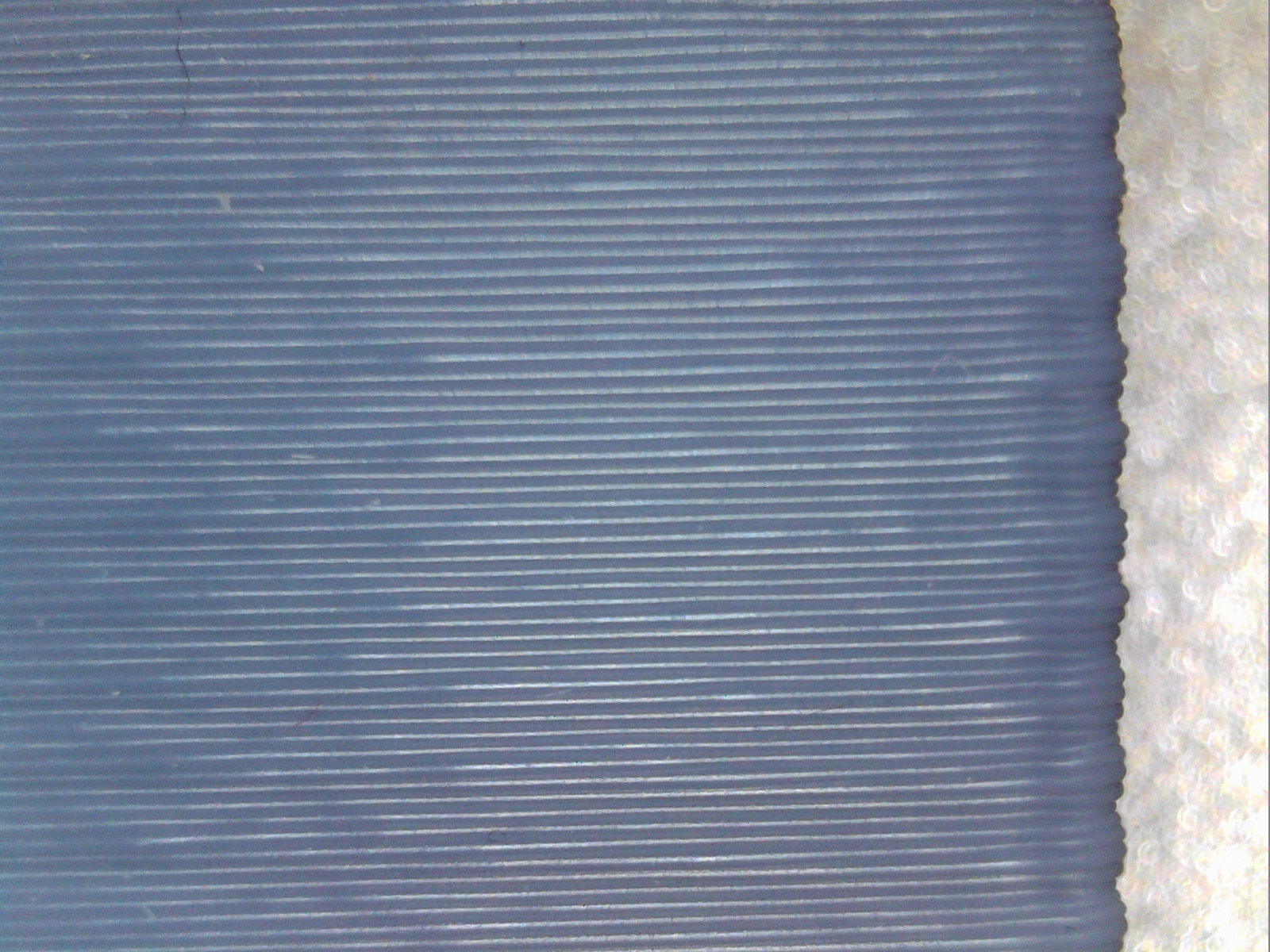

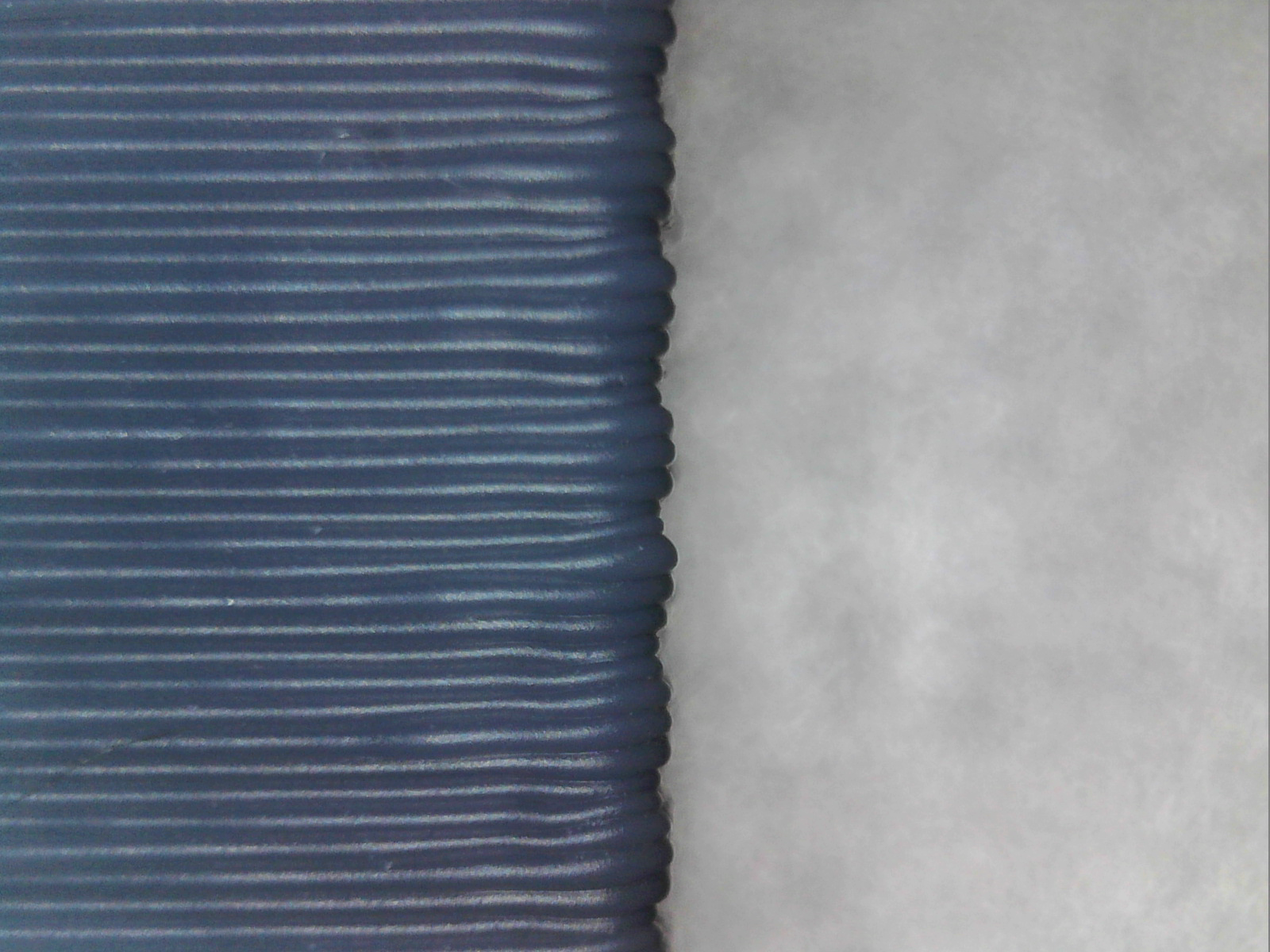

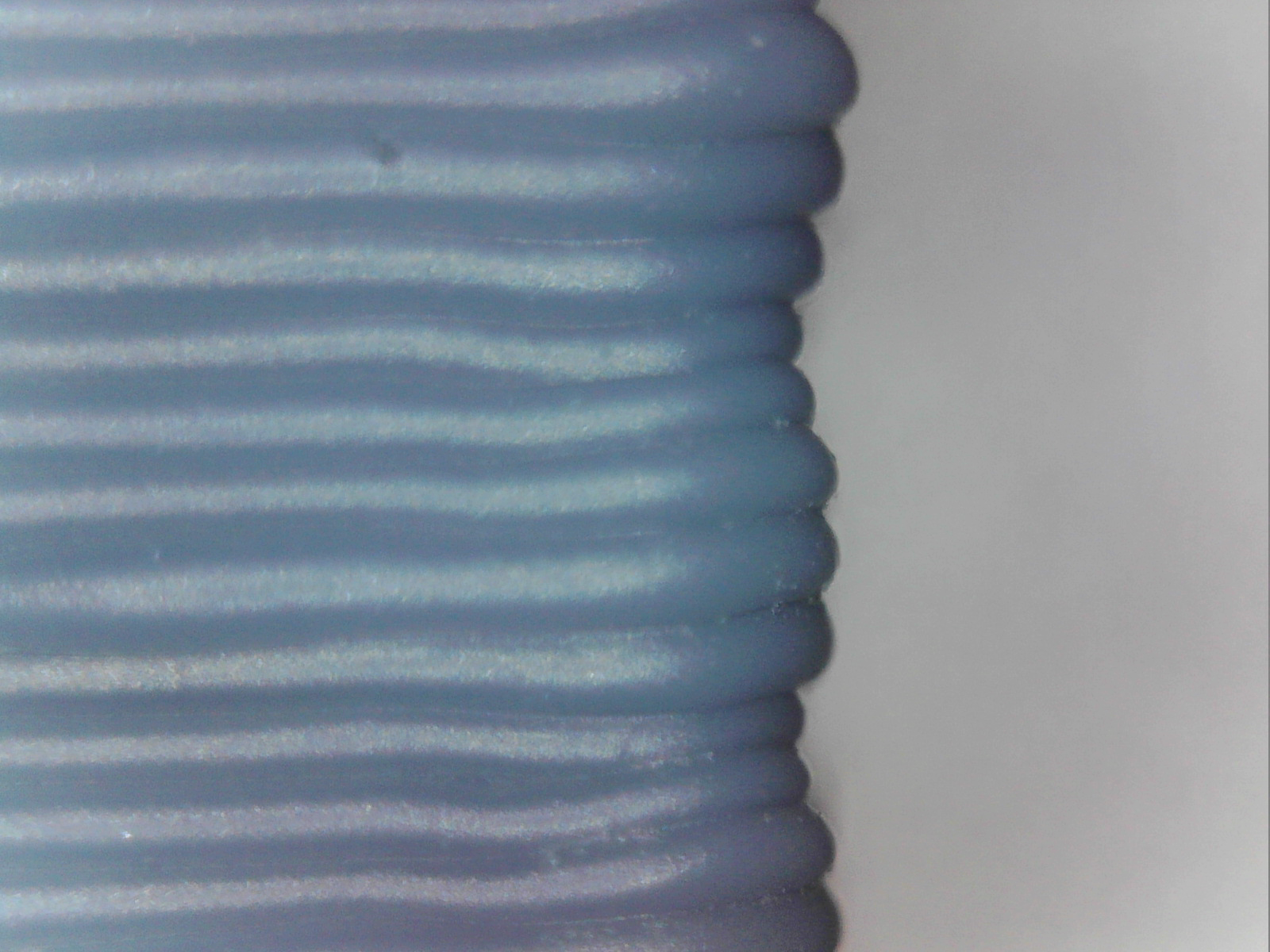

this was .2mm layer and looking at the edge it looks like the extrusion flow is pulsating

Looks like 1mm period height wise but looking it lengthwise:

-

@dc42 yeah I'm pretty much convinced it's how the worm gear works and you can get lucky and have everything aligned perfectly and you wouldn't notice the artifacts... but I think that if you look close enough you'd see them anyway. I'll try with a standard extruder to discard any possible issue with the machine mechanics and report back.

@arhi thanks for digging out your old prints. My slant lines are definitely less bad then yours were, also I can really notice them only in 1-wall prints. On normal prints the problem translates into a fuzzy texture. I have a feeling that if you print a 1 wall cube at a decent speed and look close enough you'd notice some sort of slant lines even with the new shaft.

-

@matt3o actually did a bunch of single wall prints to calibrate extruder and no slant lines with the new shaft and new hotend. I don't think I changed anything else.

-

@arhi we would need to check the same model at the same speed I guess, because if it's not the extruder I wouldn't know what else

-

That print is

- ABS (gray, one of the most unforgiving colors)

- 0.2mm layer

- 0.5mm nozzle

- 0.6mm extrusion width

- 4/4/4 (top/bottom/perimeters)

- 90% * 60mm/s outline speed

the lines are not as visible live as on the images I uploaded, that's with light coming under a very shallow angle so that effect is more prominent.

If you have a test case I'll be willing to try it out, I now have E3DV6 with .3mm mozzle on that G5 now, currently PLA loaded but I can easily switch to ABS/PETG/PC/PA

-

@arhi The pulsing could be caused by the flex cable not turning consistently/smoothly, but as @matt3o has tried it with a NEMA 8 motor (replacing the flex cable) and still has artifacts, it does seem the worm gear is most likely responsible. As I said waaaaay back at the beginning of this thread!

Ian

-

@droftarts yup, only I replaced the hotend and the shaft and the gears are still the same but lines are gone

-

It might be your shaft that caused the issues too. If could have been was pulling and yanking the little worm around. The period of the errors are the same for the worm and the cable.

I like your bracing mechnism holding the shaft in place.