Dual Y Motor Configuration

-

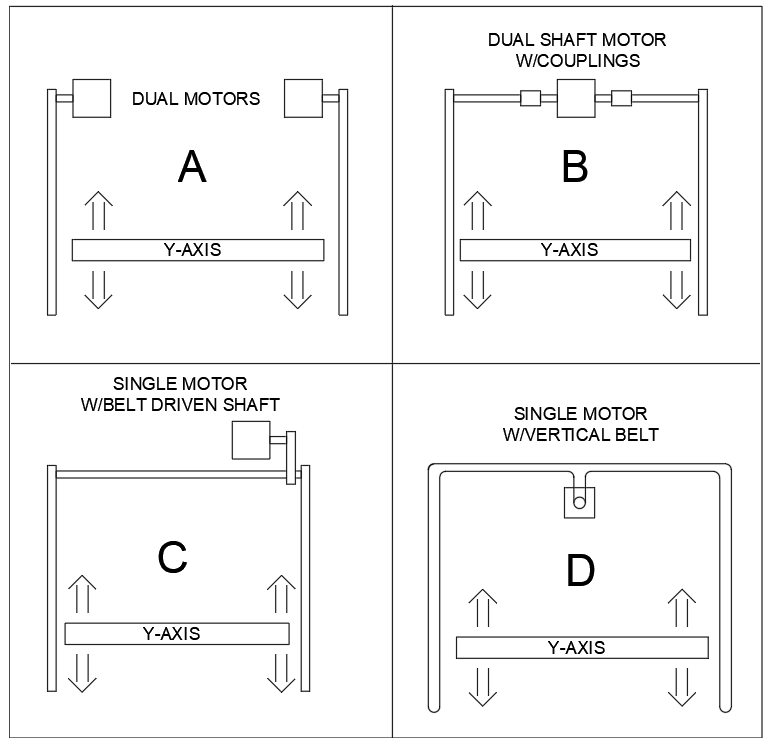

@bot No not really, I debated a few different arrangements but decided this one was the best and I had a extra driver on the duex5. Less maintenance, setup and believe it or not probably the cheapest option out of the four. If you are interested I have been posting pictures of my progress on my twitter.

!

-

@3DPrintingWorld interesting layout! I’m considering something similar for my current build, but single carriage and tool changer. See https://forum.duet3d.com/post/118078

Ian

-

What would make the single motor setup more costly? It seems with the difficulty of synchronizing the motors taken into account, it may be easier to do a single motor if the belt is not too long.

-

@droftarts That looks really cool, your extruders look sweet! What keeps your x-axis from skewing. I know without the y-axis belts on the current setup I have the x-axis would be all over the place.

-

@bot An additional stepper motor is only like $15, versus a shaft, couplings, and a couple bearings. I guess if you went with version "D" it might be cheaper, depending on the belt.

Its taking me a little bit to get the homing right but I think it will be the right choice in the long run.

-

@3DPrintingWorld pictures aren’t mine, they’re from the RepRap forums link. The ‘double’ markforge layout is basically a CoreXY, just with the idler that usually takes the belts across the top of the frame moved to the X axis. So it’s in balance, just like a CoreXY, unlike an Hbot or single-sided Y Markforge. It’s effectively yours without the Y axis belts and motors, and with one X carriage the joins the two belts, rather than having them independent.

Ian

-

@droftarts Let me know how it works out when you get it done!

-

Well, I'm not having much luck figuring out anything on my own.... I'm trying to add a second endstop to the y-axis. With one switch its working fine. When I add "+e1stop" to the M574, if either switch is touched it switches the ystop and both motors stop. What am I doing wrong here? Or do I need to add something to my homey to home two motors on a single axis?

M584 X0 U2 Y1:9 Z5:6:7 E3:4

M574 X2 S1 P"xstop"

M574 Y2 S1 P"ystop+e1stop"

M574 U1 S1 P"e0stop" -

@dc42 I was wondering if you could help me with this. I have two switches for the y-axis now. When I configure it like this all switch indicate properly in the endstops status screen.

M574 X2 S1 P"xstop" ; X min active high endstop switch

M574 Y2 S1 P"zstop" ; Y min active high endstop switch

M574 U1 S1 P"e0stop" ; U max active high endstop switchBut when I add the second endstop tag to the y axis like below the ystop switch no longer changes state only the zstop switch.

M574 X2 S1 P"xstop" ; X min active high endstop switch

M574 Y2 S1 P"ystop+zstop" ; Y min active high endstop switch

M574 U1 S1 P"e0stop" ; U max active high endstop switchCan you enlighten me to what I am doing wrong. The other odd thing is when I unplug the zstop and remove its tag from the config, it shows as triggered. Shouldn't that be the opposite?

-

@3DPrintingWorld, which firmware version are you running? Send M115 to confirm it.

Please post your complete config.g file and homing files.

-

@dc42 RRF 3.0

G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M669 K0 Y1:-1:0:1 ; select Markforged Kinematics Y to react with X and U ; Axis Limits M208 X35 Y0 U-18.4 Z0 S1 ; set axis min M208 X419 U365 Y336 Z300 S0 ; set axis max ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P1 S0 ; X physical drive 0 goes backwards M569 P1 S1 ; Y right physical drive 1 goes forwards M569 P2 S0 ; U physical drive 2 goes backwards M569 P3 S1 ; E1 physical drive 3 goes forwards M569 P4 S1 ; E2 physical drive 4 goes forwards M569 P5 S0 ; Z left physical drive 5 goes backwards M569 P6 S0 ; Z center physical drive 6 goes backwards M569 P7 S1 ; Z right physical drive 7 goes forwards M569 P9 S0 ; Y left physical drive 8 goes backwards M584 X0 U2 Y1:9 Z5:6:7 E3:4 ; set drive mapping M350 X16 U16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X100.00 U100.00 Y100.00:80.00 Z1096:1096:1096 E1827.00:1827.00 ; set steps per mm M566 X900.00 U900.00 Y900.00:900.00 Z12.00:12.00:12.00 E40.00:40.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 U6000.00 Y6000.00:6000.00 Z1000.00:1000.00:1000.00 E1800.00:1800.00 ; set maximum speeds (mm/min) M201 X500.00 U500.00 Y500.00:500.00 Z20.00:20.00:20.00 E120.00:120.00 ; set accelerations (mm/s^2) M906 X800 U800 Y800:800 Z200:200:200 E500:500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Endstops M574 X2 S1 P"xstop" ; X max active high endstop switch M574 U1 S1 P"e0stop" ; U min active high endstop switch M574 Y2 S1 P"ystop" ; Y max active high endstop switch ;M574 Y2 S1 P"ystop+zstop" ; Y Double max active high endstop switch ; Z-Probe M671 X-20.6:200:420.6 Y14.3:333.3:14.3 S2 ;Locations left, center, right M950 S0 C"duex.e6heat" ; create servo pin 0 for BLTouch M558 P9 C"zprobe.in+zprobe.mod" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P25 X28.8 Y0 Z2.15 ; set Z probe trigger value, offset and trigger height ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4534 C9.565227e-8 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M308 S2 P"e1temp" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M143 H2 S280 ; set temperature limit for heater 2 to 280C M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off M950 F3 C"duex.fan8" Q500 ; create fan 3 on pin duex.fan4 and set its frequency M106 P3 S1 H2 T45 ; set fan 3 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 X3 F0 S"Left" ; define tool 0 left G10 P0 X0 Y-1.2 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 F2 S"Right" ; define tool 1 Right G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P2 D0:1 H1:2 X0:3 F0:2 S"Copy" ; define tool 2 copy G10 P2 X-75 Y0 U75 S0 R0 ; set tool 2 axis offsets M567 P2 E1:1 ; set mix ratio 100% on both extruders M501 ; Record; homeall.g ; X,U,Y Homing G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X475 U-475 Y500 F1800 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X475 ; home X axis G1 H1 U-475 ; home U axis G1 H1 Y500 ; home Y axis G1 X-5 U5 Y-5 F6000 ; go back a few mm G1 H1 X25 F360 ; move slowly to X axis(second pass) G1 H1 U-25 ; move slowly to U axis(second pass) G1 H1 Y25 ; move slowly to Y axis(second pass) ; Z Homing G90 G1 X171 Y150 F10000 ; Move to the center of the bed M558 F500 ; Fast probing speed G30 ; First probe M558 F50 ; Slow probing speed G30 ; Second probe G32 ; Level the bed G90 G1 X171 Y150 F10000 ; Move to the center of the bed G30 ; Bed Deviation probe G90 G1 X417 ; Park x-axis