Dual Y Motor Configuration

-

@dc42 That's not too important to me but it might be to other who might build this printer and use my configuration. I already have a physical endstop switch. Is it possible to stall out on the one end then lastly use the physical end stop for a more accurate home?

I was working on this last night but my stall detection was not working unless I specified sensorless homing in the config -

I got sensorless homing to work but the dual y axis motors are still tied together. What am I missing?

Config

M584 X0 U2 Y1:9 Z5:6:7 E3:4M574 Y1 S4

Homey

M915 Y S10 R0 F0 -

@3DPrintingWorld said in Dual Y Motor Configuration:

I got sensorless homing to work but the dual y axis motors are still tied together. What am I missing?

What exactly do you mean? The motors should indeed be tied together, except that when homing them they should stop individually as they stall. Bear in mind that when one motor stall, the other will be moving the carriage by itself; so the load on it will increase, and if the stall threshold is set too low then it may report a stall immediately.

-

@dc42 It seems to work well but one side is not making contact with the frame. Both motors seem to stall at the same time. I see what you are saying about the increased load on the other motor. If I turn the threshold up the belts start skipping before the other end makes contact with the frame. I have the motors turned down to 30%, do I need to increase the speed with the threshold? The thing is, It really does not take much torque to skew the frame which is why I'm relying on the motors to keep it square.

Seems like I have something wrong with the programming. Is my M915 command right in my Homey script? It knows that "Y" is two motors.

-

@3DPrintingWorld said in Dual Y Motor Configuration:

If I turn the threshold up the belts start skipping before the other end makes contact with the frame

Are you sure that is it possible for the second motor to carry on turning, without the axis binding and that causing a stall?

-

@3DPrintingWorld What firmware are you on? You need to be on RRF 3 for this to work properly as you have it set up at the moment, not RRF 2. Send M115 at the console, and post reply.

Ian

-

@dc42 I think you might be right! The attached picture shows the belt arrangement. Maybe the X and U axis's are keeping the X-axis from twisting. I will try taking the second motor(P9) out of the config and see if I can move it with my finger after its been homed.

I do see an issue that the x(u) carriage must be away from the switch(end of travel) when homing the Y otherwise when the Y motor stalls the x(u) carriage will be pulled into the switch. My plan for home all was to home X & U first then move them away from their switch before homing the Y.

Is it possible to turn the x and u axis off the moment the Y detects a stall?

-

@droftarts Yep, I just switched to RRF 3 last night. I can do this when I get home but I think the issue may be that the belt arrangement is keeping the x axis from twisting. I will confirm both tonight.

-

@dc42 I tried multiple things, I can verify that the issue was not that the motor could not turn. I ended up getting it to work once I turned up the motor current to 50%. If I turned that up any more or the S value I would get skipping. The first time its homed and its far out of skew the farthest side does not always make contact. Then by the second or third time it always makes contact but has the tendency to bounce off.

I think I'm just going to add a second switch to the Y axis and hopefully call it a day.

-

That's an interesting belt arrangement. Is the reason you did not drive the Y axis from one motor because you couldn't get a belt long enough to go around the whole way?

-

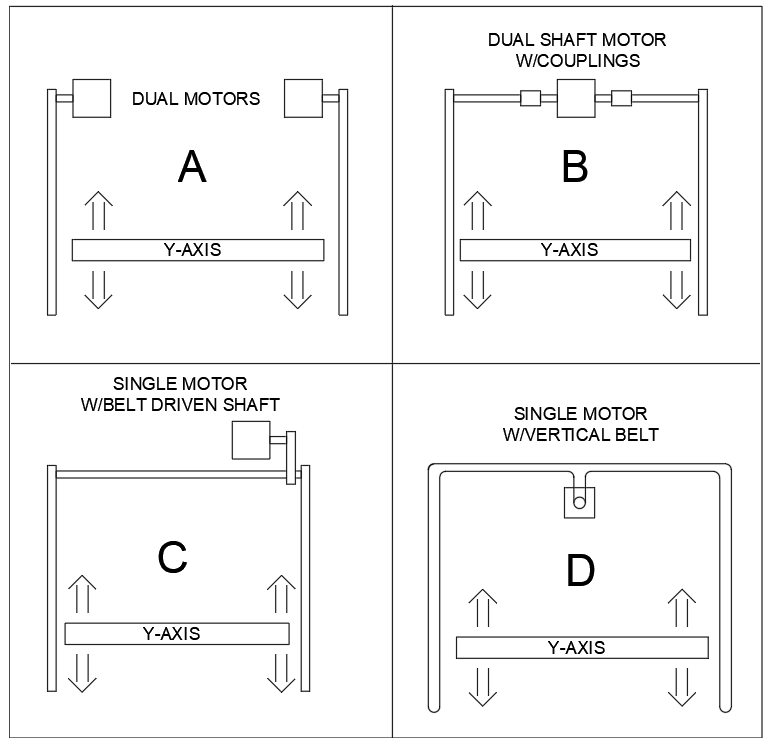

@bot No not really, I debated a few different arrangements but decided this one was the best and I had a extra driver on the duex5. Less maintenance, setup and believe it or not probably the cheapest option out of the four. If you are interested I have been posting pictures of my progress on my twitter.

!

-

@3DPrintingWorld interesting layout! I’m considering something similar for my current build, but single carriage and tool changer. See https://forum.duet3d.com/post/118078

Ian

-

What would make the single motor setup more costly? It seems with the difficulty of synchronizing the motors taken into account, it may be easier to do a single motor if the belt is not too long.

-

@droftarts That looks really cool, your extruders look sweet! What keeps your x-axis from skewing. I know without the y-axis belts on the current setup I have the x-axis would be all over the place.

-

@bot An additional stepper motor is only like $15, versus a shaft, couplings, and a couple bearings. I guess if you went with version "D" it might be cheaper, depending on the belt.

Its taking me a little bit to get the homing right but I think it will be the right choice in the long run.

-

@3DPrintingWorld pictures aren’t mine, they’re from the RepRap forums link. The ‘double’ markforge layout is basically a CoreXY, just with the idler that usually takes the belts across the top of the frame moved to the X axis. So it’s in balance, just like a CoreXY, unlike an Hbot or single-sided Y Markforge. It’s effectively yours without the Y axis belts and motors, and with one X carriage the joins the two belts, rather than having them independent.

Ian

-

@droftarts Let me know how it works out when you get it done!

-

Well, I'm not having much luck figuring out anything on my own.... I'm trying to add a second endstop to the y-axis. With one switch its working fine. When I add "+e1stop" to the M574, if either switch is touched it switches the ystop and both motors stop. What am I doing wrong here? Or do I need to add something to my homey to home two motors on a single axis?

M584 X0 U2 Y1:9 Z5:6:7 E3:4

M574 X2 S1 P"xstop"

M574 Y2 S1 P"ystop+e1stop"

M574 U1 S1 P"e0stop" -

@dc42 I was wondering if you could help me with this. I have two switches for the y-axis now. When I configure it like this all switch indicate properly in the endstops status screen.

M574 X2 S1 P"xstop" ; X min active high endstop switch

M574 Y2 S1 P"zstop" ; Y min active high endstop switch

M574 U1 S1 P"e0stop" ; U max active high endstop switchBut when I add the second endstop tag to the y axis like below the ystop switch no longer changes state only the zstop switch.

M574 X2 S1 P"xstop" ; X min active high endstop switch

M574 Y2 S1 P"ystop+zstop" ; Y min active high endstop switch

M574 U1 S1 P"e0stop" ; U max active high endstop switchCan you enlighten me to what I am doing wrong. The other odd thing is when I unplug the zstop and remove its tag from the config, it shows as triggered. Shouldn't that be the opposite?

-

@3DPrintingWorld, which firmware version are you running? Send M115 to confirm it.

Please post your complete config.g file and homing files.