zProbe - drift in small measurements

-

Hello!

I am currently calibrating a new Delta and although I have now built 4 of those I get a calibration problem I cannot remember ever having before.

First I am moving along the trusted guide in this respect: https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printerThe Piezo-Precision Endstop works reliably enough to have the mesh bed leveling with more than 130 points without an error.

In preparation to verify the sensor is working reliably I wrote a script for Homing and than moving all the way down, probing, than back up again.

Then agan the same movement with fast travel down to shave of time. I get a standard deviation of 7 micron and 4 micron and a total range of 20 micron and 10 micron respectively. So far so good, but now the weirdness starts...When I try to check the repeatability of the probing from Z5 to the bed, I usually do 20 runs, the results drift gradually.

I had first results of 742 micron and a last of 672 micron or 782 micron. But the result is not moving to the other extreme in one step. From one measurement to the next there usually is not a bigger step than 10 micron, while 50% of the time it also stays the same (48 micron for 4 cycles for example) and rarely it jumps back. This leaves me with an awful ... in StDev and ... of overall range.

But the exciting thing about this is that this only happens when I only go up Z5. When I conduct the same test run with Z25 or Z250 the results improve. For Z25 the StDev is 7 micron and the range 20 micron. For Z250 11 micron StDev and 30 micron range.

Of course some of that effect can be due to changing temperatures. The printer is made from aluminium and the distance between the probing point and the endstops is a meter, the total travel app. 700mm. That would grow the frame by 23micron per C. However this effect should be most visible when Homing and probing again and again. But there is no such effect visible.

Last but not least drift appears to be growing the finer my approach macros are. I wrote the small scrip G91 -> G1 Zn -> G90 for n=-0.01/-0.02/-0.03 and it appears the smaller the movements I use to approach the further I get (when approaching manually).

So how can it be that the probing point drifts into one direction when I use small movements? Any suggestions? My thought is, that if there is such a drift in repeated measurements on the same spot it might as well be the case during the mesh bed leveling, which defeats the purpose of the same and explain a sort of bent mesh bed visualisation.

-

On top of that, I noticed that the speed of the probing changes sometimes. So sometimes it probes at appr. F500 and ignores the F300 and sometimes it goes with the regular F300.

M208 S1 Z-3 G28 Z M561 M564 S0; Allow movement below software endstop G1 Z2 F8000 M558 P1 I1 R0.8 F300; Adjust probing characteristics: Standard Speed F500 M291 P"Adjust height until nozzle grips paper" R"Please adjust..." S2 T0 Z1 G92 Z0; define new height G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mmIn this case the probing speed and corresponding measurements were as follows:

slow 0.112

fast 0.082

fast 0.082

slow 0.112

slow 0.112

slow 0.112

slow 0.102

slow 0.112

slow 0.102

fast 0.072It is obvious that the measurements vary according to the probing speed, however I set the probing speed at the start, to make sure, but did not adjust the probing speed in between the cycles, and the config.g probing speed is also at the F300.

-

The vaying-probing-speed-problem also appears when doing a multi-probe Delta Calibration, so much so that the default tolerance is being triggered.

And another problem also appears randomly. I don't know whether it is the same underlying issue, but I'll just throw it against this wall and see whether someone can make sense of it: Sometimes when I home axis W, Axis A is also moving albeit into the wrong direction. Sometimes when I approach the heatbed (sometimes when I type G1 Z1, xyz towers move down) A also moves along, usually the xyz movement is slower then but accelerating slowly as well.

... I am Using a Duet WiFi V1.02 with a Duex5 V0.9

Firmware Name: RepRapFirmware for Duet 2 WiFi/Ethernet

Firmware Electronics: Duet WiFi 1.02 or later + DueX5

Firmware Version: 2.03 (2019-06-13b2)

WiFi Server Version: 1.22

Web Interface Version: 1.22.6 -

Please try upgrading to the latest 2.04 RC. There were some delta bugs in 2.03.

-

OK, I switched to 2.04 RC and the speed of the axis is good now!

It does not randomly mix slow with quick moves during delta calibration.However, I just homed axis W and it moved axis A into the wrong direction at the same time. So this is not fixed yet.

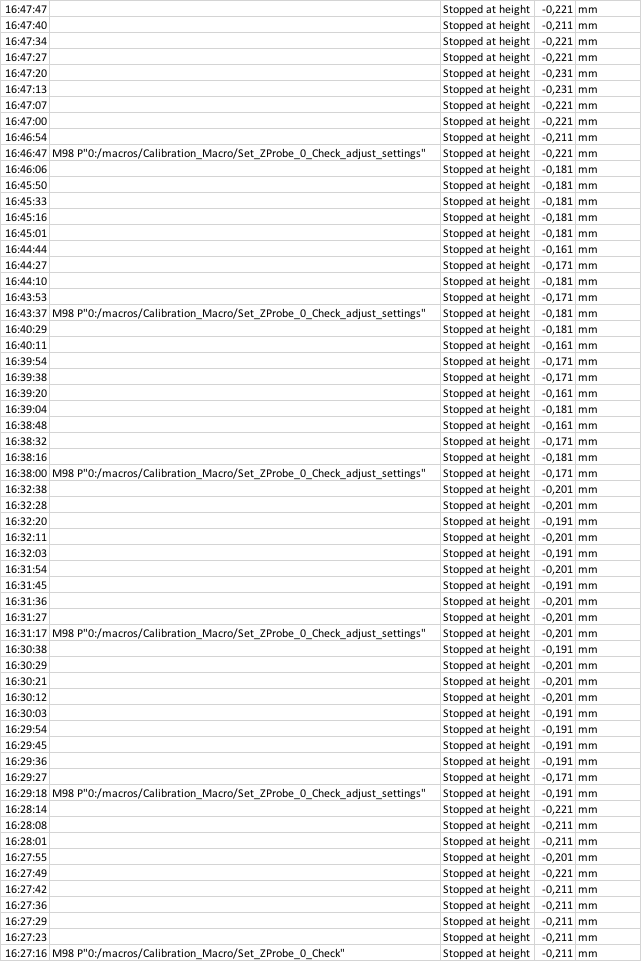

Due to the probing speed staying the same now, I do not have the issue anymore of strong variations in probing speeds, however I am still losing steps after multiple measurements:

0.022 mm

0.032 mm

0.032 mm

0.032 mm

0.032 mm

0.032 mm

0.032 mm

0.032 mm

0.032 mm

0.032 mm

0.042 mmSo the drift is still there but smaller. This obviously does not hurt with simply z-probing, but seriously screws with mesh bed leveling... any ideas?

First thing I need to straighten up is the belts seem to have some play, leaving slight but still visible valleys in the mesh grid heightmap.

-

@Deltasquare said in zProbe - drift in small measurements:

zo-Precision Endstop works reliably enough to have the mesh bed leveling with more than 130 points without an error.

In preparation to verify the sensor is working reliably I wrote a script for Homing and than moving all the way down, probing, thanhave you try normal endstop and repeat the mesurement

-

So the drift disappears when I increase the drop value to Z25 and the speed to F300.

-

@poohzaza I tried homing up and then measure z0 20 times. I wrote that above for slow and fast approach (towards the bed): "I get a standard deviation of 7 micron and 4 micron and a total range of 20 micron and 10 micron respectively."

So it quite certainly has to do with the z-probe.Its a piezo precision probe setup, so the triggering takes place when the nozzle head actually touches the Heatbed. So I didnt discount the possibility that there ma be steps lost.

However, as far as I understand it, a stepper motor can not loose microsteps, but full steps only. So the steps should stay the roughly the same, maybe jump around a little bit due to late or early zprobe-triggering. So a broader spread of measurements... But should the zprobe measurement gradually decrease? I don't think so. -

Well, now I get the impression it actually loses steps.

It is a contact probe, so the value reported should be negative. However, even though repeated measurements are now within 10micron or so total range, they repeated values start negative, but end up being positive:

G28 Z G1 Z25; Bring effektor in position T0 P0; Select Tool 0 do not run tool change mechanism G30 S-2; probe bed and adjust Endstop M558 P1 I1 R0.8 F300; Adjust probing characteristics: Standard Speed F500 G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mmResults:

-0.138 mm

-0.078 mm

0.012 mm

0.122 mm

0.132 mm

0.122 mm

0.132 mm

0.132 mm

0.122 mm

0.132 mmThe first measurement is perfect, or at least a perfect spot to start. But why is it than creeping to 0.1something. Am I missing something?

-

Its mind numbing...

Even when I follow the guide:

Calibrate Z ProbeI have no contact with the bed at 0.1something, and only slightly grips a piece of paper at 0.02 and properly at 0. So I do not G92 Z0.

I Jog up 25 (because thats the most reliable height)

Than I do G30 S-1. Now I get 0,112. Why is it positive?

-

@Deltasquare said in zProbe - drift in small measurements:

Piezo-Precision Endstop

i think it a sensor crucuit have you try report this to manufacture

have you try probe slowly and delay 1 second

-

@Deltasquare said in zProbe - drift in small measurements:

However, as far as I understand it, a stepper motor can not loose microsteps, but full steps only.

It can only lose multiples of 4 full steps.

-

I thought so, because it wouldn't improve the further up I move (Z5 vs Z25).

Please just help me for a moment there... If I have 200 Steps per revolution and a GT2 with a pitch of 2mm on a 16tooth pulley. So

(2*16)/200

... therefore I have 0,16mm per FullStep and but would lose at least 0,64mm as I would at least lose 4 full steps.

So, if i consider only homing vertically at X0 Y0 I do not have to take into consideration the different kinematic angles up at the top.

So, just that I am certain with my reasoning: If I lose 0,64mm or more it has to do with lost steps in the delta, if it is any less... @dc42 what else could it be?

Is there a error in my reasoning?

Does G30 S-1 even work in this setup?

How do I properly integrate G30 S-3 into my first macro?

-

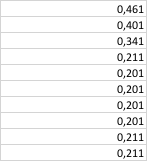

So these were my latest results:

with the following gcode:

;G31 X0 Y0 Z0 P780; Set Z Probe to 0 offset and Sensitivity to 780 G1 Z25; Bring effektor in position T0 P0; Select Tool 0 do not run tool change mechanism G30 S-2; probe bed and adjust Endstop M558 P1 I1 R0.8 F300; Adjust probing characteristics: Standard Speed F500 G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mm G30 S-1; probe the bed without resetting G1 Z25; nozzle up 5mmWhat am I doing wrong? Or is it a hardware thing?

-

@poohzaza Yeah, the M558 Recovery time at 0.8, will try with 1. However that shouldn't make too much of a difference I think. Speed is at F300. Can can still lower it, to see if it makes a difference.

-

Apparently it works now. It kills me not to now why. Is there some sort of gcode that allows for continuing adjustment of the zprobe that I may have had switched on previously? ...

Will now start the printer new and see whether it persists. -

M558

Recovery time at 1 does not change a thing.

Speed at F100 does neither improves nor detriotates measurementsCan anybody help me?