Config.g error or problem in clearpath setup ? Homing...

-

Thank you for reply.

Teknic - 3426P servo motorBtw. i have try to change steps per mm, speed, M569 T value, but situation is the same

Motor settings in MSP setup is set to 800 RPM.Config.g

General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmare

;------------------------------------------------

M669 K10 U380 L980 A-10:7.3 R15 H1000 B600 ; rotary delta FW

M669 X150 Y150 Z150 ; rotate +X direction by 150deg

M666 X0 Y0 Z0 ; Put your endstop adjustments here

M574 X2 Y2 Z2 S0 ; END STOP SWITCHES; Drives

M569 P0 S0 ; Drive 0 goes backwards

M569 P1 S0 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes forwards

;------------------------------

M569 P5 R0 T3:3:3:3

M569 P6 R0 T3:3:3:3

M569 P7 R0 T3:3:3:3

M584 X5 Y6 Z7 E3:4

;-------------------------------

M92 X89 Y89 Z89 ; Set steps per mm

;M92 X200 Y200 Z200 ; Set steps per mm

M350 X16 Y16 Z16 I0 ; Configure microstepping without interpolation

;-------------------------------

M566 X2000 Y2000 Z2000 E ; Set maximum instantaneous speed changes (mm/min)

M203 X10000 Y10000 Z10000 E0 ; Set maximum speeds (mm/min)

M201 X2000 Y2000 Z2000 E0 ; Set accelerations (mm/s^2)

M906 X2100 Y2100 Z2100 E800 I70 ;Set motor currents (mA) and motor idle factor

M84 S15 ; Set idle timeout..; Axis Limits

M208 Z100 S1 ; Set minimum Z

; Endstops; Z-Probe

M558 P1 H5 F120 T6000 ; Set Z probe type to unmodulated

G31 P500 X0 Y0 Z2.5 ; Set Z probe trigger value, offset and trigger height

M557 R400 S20 ; Define mesh grid -

the motors are rated at 24-75 VDC. Why do you want to try and run them at 5V?

what voltage are you running on?what current are you running the motors at?

how are the motors connected to the duet? and how are they configured?

-

Please be so kind and look at this post:

https://forum.duet3d.com/topic/8876/clearpath-servomotor-50nm-suggestion/33They are powered with 72V and 5V is for logic part.

A.

-

it might be better if you continue in that thread and not spread it across 2 threads.

-

OK, I just watched your video on my PC, couldn’t view it on my iPad. Those don’t look like Clearpath servos?

I don’t know how microstepping effects the driver in the Clearpath servos, I would not use microstepping. Clearpath software setup has a frequency setting which effects steps per mm similar to microstepping. -

Hi edkirk, glad to hear you.

Yep. They are clearpath servos. 3426P-rnl model.

I have set 800 rpm in msp setup and i have copy/pasted this setup to all motors.

OK i will try without microstepping.

So you think that i dont need to use 5V instead of 3,3 ?

BTW. How did you calculate 200 mm/step in you setup, or did you test it manualy ?- i started new thread because this is now just sw settings, it has nothing to do with hw.

Anyhow, thank you for your input !

A.

- i started new thread because this is now just sw settings, it has nothing to do with hw.

-

Steps per mm is calculated to achieve “steps per mm”. Rotary motion equals a set amount of travel which is effected by microstepping. If you double the frequency in Clearpath you will double the Steps per mm. The higher the frequency the smoother the motor, there is probably a functional limit.

I run steps per mm some where around 200 to get a pretty smooth finish in the arcs. It will probably not be exactly 200 or even very close. 168.73 maybe higher, 238.125 whatever it comes out at to achieve proper travel. I installed an extra reduction on more Core XY to increase from 80’s to to mid 200’s. Higher resolution = smoother motion= cleaner surface

Mine run just fine off of the Duet control voltage.

If your microstepping is 16 and you remove it your travel will be reduced by an equal factor, probably just barely crawl. -

Hi Arnix_2,

I'm an applications engineer for Teknic and I thought it would be helpful to chime in here. Without more information, it's difficult to say for sure what the issue could be, but one of our engineers would be happy to assist with troubleshooting if you are interested.

Please feel free to contact support@teknic.com and an engineer will contact you shortly after.

-Bridgette G. - Teknic Servo Systems Engineer

-

@teknic_servo said in Config.g error or problem in clearpath setup ? Homing...:

Hi Arnix_2,

I'm an applications engineer for Teknic and I thought it would be helpful to chime in here. Without more information, it's difficult to say for sure what the issue could be, but one of our engineers would be happy to assist with troubleshooting if you are interested.

Please feel free to contact support@teknic.com and an engineer will contact you shortly after.

-Bridgette G. - Teknic Servo Systems Engineer

@Teknic_Servo, thanks for stepping in. FYI, in these commands:

M569 P5 R0 T3:3:3:3

M569 P6 R0 T3:3:3:3

M569 P7 R0 T3:3:3:3the 3:3:3:3 specify the minimum step pulse width, step pulse interval, direction-to-step setup time and step-to-direction hold time (from the leading edge of the step pulse) respectively, in microseconds.

@Arnix_2, for a rotary delta the M92 command must specify the steps per degree of rotary arm movement.

-

@dc42

OK. I'm writing mail to tecknic support and i will copy paste full reply.

Steps per mm:- am not quite sure how should i calculate/set this because only thing i can set in MSP tecknic SW is RPM but everything else should be set "manually".

I know i have to calculate micro stepping*10/1.8 degree (or other value depending on motor), but that's all. - ups, i found reply in previous posts...

@Edkirk

I found one interesting option in fine tuning setup, and i set slider to "quietness" . The result is very interesting. There are almost no vibrations and upper arm and is moving very smoothly. Speed is reduced quite a lot but not so much that it would affect whole movement. - am not quite sure how should i calculate/set this because only thing i can set in MSP tecknic SW is RPM but everything else should be set "manually".

-

Good day to all !

I got reply from tecknic support and it looks like that the motors should be auto configured with full load. So i dismantled each motor from the construction ( didnt want to copy/paste saved data ) and run the config again. It looks like it has worked.Now i am bit confused what is happening when i try to home all axis.

It looks like if the motors have some kind of torque protection when they hit endswitch ( i will ask tecknic about that too ) because after the arm hits endswitch, hand starts to drop down slowly and i can not controll it from web gui anymore. I can still send commands from gui and this is working normally, it just looks like if the power of the motor is cut off.After i click emergency stop and restart is done, motors are back "online"..

I have attached video, because it's hard to describe this.

Btw. in this video, Z axis is not homed correctly, which is weird, because i can see that LED blinks on the endswitch and on the duet board.

https://gofile.io/?c=3cYPIC -

I dont know what was the problem but i have setup motors completely from the beginning and now it looks like everything is OK. Even the homing is working.

Now i need to setup fine tuning for duet's config

so if someone can take a look, it would be great. The problem is that i get intermediate position outside machine limits error, when i try to execute some basic command like G1 X10 Y10 F300. I get the same error when i try pressing any X/Y/Z value under "head movement" part.

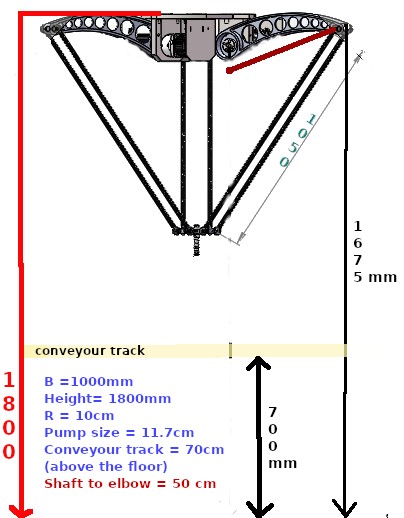

so if someone can take a look, it would be great. The problem is that i get intermediate position outside machine limits error, when i try to execute some basic command like G1 X10 Y10 F300. I get the same error when i try pressing any X/Y/Z value under "head movement" part.To understand all this a bit clearer i made some photo with actual dimension and calculations ( when the arms are in horizontal with motor shaft ) and i attached part of config.g file.

IMHO, i think i have set everything correctly accept degree calculation.

;****FOR ROTARY DELTA SETUP

; B == bed radius = 1000mm - working radius

; H == Height--> base center <--> floor = 1800mm

; R == 15-5 = 10cm ( base centar --> motor shaft )

; A == arcsin /31

;------------------------------------------------

M669 K10 U500 L1050 A-10:7.3 R10 H1800 B1000

M669 X150 Y150 Z150 ; rotate +X direction by 150deg

M666 X0 Y0 Z0 ; Put your endstop adjustments here

M574 X2 Y2 Z2 S0 ; END STOP SWITCHESM92 X90 Y90 Z90

M350 X16 Y16 Z16 I0;///////////////// HOMING FILE ///////////////////////////////////

G91 ; relative positioning

G1 S1 y-60 X-60 Z-60 F1000 ; move all towers to the high end stop at endstops

G1 S2 X13 Y13 Z13 F700 ; go down a few mm

A.

-

any ideas ?

-

After homing, when you send G90 G1 S2 X0 Y0 Z0 it should set all 3 arms horizontal, i.e. outer and inner bearing centres at exactly the same height. Does it?

-

Homing

G91 ; relative positioning

G1 S1 y-60 X-60 Z-60 F1000 ; move all towers to the high end stop at endstops

G1 S2 X13 Y13 Z13 F700 ; go down a few mmWhen the homing part is done, all 3 arms are full horizontal with motor shaft.

If is send G90 G1 S2 X0 Y0 Z0 afterward, all 3 arms move up and they are trying to move above endstops. Because of that, motors are shuted down as they detect over torque limit.A.

-

UPDATE:

- if i run homing ( like it's described in upper post ) any other command after homing , will produce that arm moves up and hit the switch. Funny thing is that if i dont make the homing part, i can normaly work with each arm.

In other words, If i run G1 S2 X0 Y0 Z0 F300 after homing, all arms will go up and they will hit endswitch. The same will happend if i enter any other command ( for one arm movement ) like, G1 S2 X10 F300 or G1 S2 X-10 F300 etc...

If i run separate command without homing, then i get clear movement.

e.g. without homing and after i run G1 S2 X0 Y0 Z0 F300 , all arm are positioned down.Any ideas ?

-

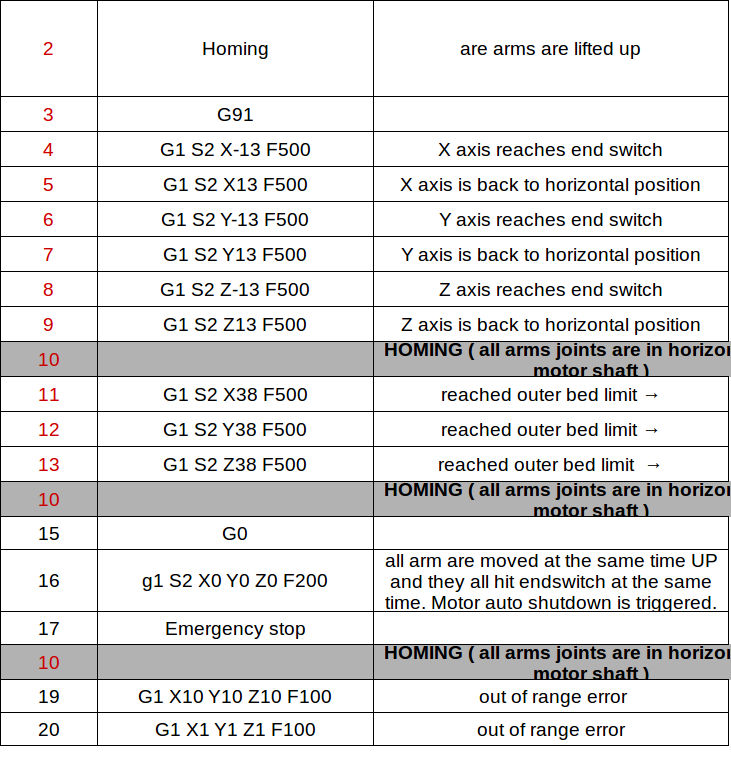

I still can not find any solution why is this happening. If someone can take a look at test sequence and tell me what can be wrong... Thank you all in advance...

2 Homing are arms are lifted up

2 Homing are arms are lifted upTest is made line by line in the order that is described in first row...

Basically, i can control each motor without problem but when i enter standard gcode command, i get out of range error, regardless what value i enter... -

@Arnix_2 step 16 looks to be where the problem is (although i don't have a rotary delta so can't be sure).

Why have you set the Homing positions as minimums not maximums? I would have thought that (like a normal delta) the arms are at their highest (maximum) position when homed and the effector moves down to Z0 when they are extended?

What is the distance from your current arm triggered position to X0 Y0 Z0 (which i assume is with the effector at the correct point touching or just above the belt?

Have you tried setting you M208 so that the endstop triggers a X, Y,Z Max not Min?