Z axis design advice.

-

Hi all,

I am considering a Z axis upgrade for my CoreXY. I recently converted from an ultimaker-like gantry to a CoreXY system based on linear rails running on Duet wifi board. But Z is still based on some old hardware i had from a previous system.

Some background:

Headbed is relatively small (220x220) and right now it is running on a cantilever design. I made the construction of it as rigid as i can, given the hardware (2 linear rods of only 8mm and an 8mm Tr8x8 ACME leadscrew). In slow speeds (30-40mm/s) everything looks stable and the print quality is OK. Higher speeds i get some irregularities on the walls (visible only when light hits on the "bad" angle) which i think is due to my design's limitations (mechanical resonance, mainly in infill and sharp corners). That is not to say that quality is bad, but i am trying to achieve the best i can given the hardware i can use.Now, i have some hardware laying around, enough to convert my Z axis with 2 lead-screws (on opposing ends), 2x12mm linear rails etc. But i am struggling on deciding on whether i should just use 2 motors (one on each leadscrew) or 1 motor with belt/pulleys system to drive the leadscrews. It seems to me that with 1 motor and a belt the synchronization issues should be mitigated? I have read a few posts from a quick google search but i was not able to come to conclusion. From the forums i also got the idea that 1 motor is better, but the most popular solution still seems to be the more straightforward with 2 motors. Am i missing an advantage of the 2 motor system over the 1 motor/belt?

On top of that, in case of 2 motors, any advice considering how it is better to connect them in order to avoid synchronization issues (if it is possible..?), in series using the ZA,ZB or independent using the E1 driver? Given that at the moment i am not using any bed leveling sensor, and i print on glass. I rarely have to re-level the bed, but i was considering trying a BL-touch some time ago..

The motors i am using are: https://reprapworld.nl/datasheets/SL42S247A.pdf and the system is running on 12V with 30A PSU.

Even though i would like the 3 independent motor and 3 point bed leveling system like this one (https://www.youtube.com/watch?v=ItAonH9IVy0), it is not an option at the moment, both due to time/budget constrains (student).

Thanks in advance and sorry for long post/possible language mistakes!

-

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

Here's how you can keep two motors synced up and level the bed. I wouldn't use two motors without doing something like that.

I use 1 motor belted to 3 lead screws and that also works well.

-

@dkos I have 3 z axis and 3 motors, two are wired together. I use 2 of the z outputs on the duet wifi and they stay insync. However keeping the bed level has been a nightmare until i tied all 3 together via a gt2 timing belt. They now stay insync and rarely need to level the bed. After nearly a year i was having issues with the bed so i took apart one of the 3 motors and just use it as an idler. It runs pretty well now except for the occasional clash of the motors which results in some horrendous noise, skipped steps and stuff but this is only happened a few times and not during a print and did not put it out of level. The makers of the machine suggest only one motor is adequate, that would for sure solve the sync problem.

-

@Phaedrux I read this documentation and it is indeed the way to go for 2+ motors which also required a probe to achieve the leveling. It is good to know that it solves the synchronization problem.

In the case of 1motor with belt/2 leadscrews do you think is enough for a stable and trouble free bed (once setup), taking into account the relatively small size of the bed?

-

@brian "The makers of the machine suggest only one motor is adequate, that would for sure solve the sync problem." That is what i have been thinking as well, i was just not sure if 2 lead-screws/1motor would be enough for the job.

That is actually an interesting idea, of having two Z motors connected in series and connect them mechanically as well with a belt to guarantee an insync operation. But i guess once you do that you cannot use the article the @Phaedrux suggested to synchronize via software. And then the question is, which method is more reliable..

-

@dkos My printer bed is 21X21 inches and quite heavy, and i have no trouble with only 2 motors 3 leads screws. If anything stops working i will try only one motor, but right now its printing better than ever. Actually i will be replacing the lead screws with ball screws, just waiting for a new and longer timing belt to arrive.

-

@brian Thats a quite large heatbed! Thanks for the info though, and good luck with the upgrade!

-

I think that a belted three-screw/one stepper solution is awesome. Three points determine a plane, so having the print bed connected to three leadscrews puts that bed on a planar connection, and with the belted solution the three points are always in sync with each other (minus IMHO negligible belt stretching or the like). With a 3 or 4:1 reduction via the pulleys used on the Z axis leadscrews and the stepper, you get extremely fine-grained Z axis movement, while the mechanical advantage of that reduction also means that one stepper can handle quite the load.

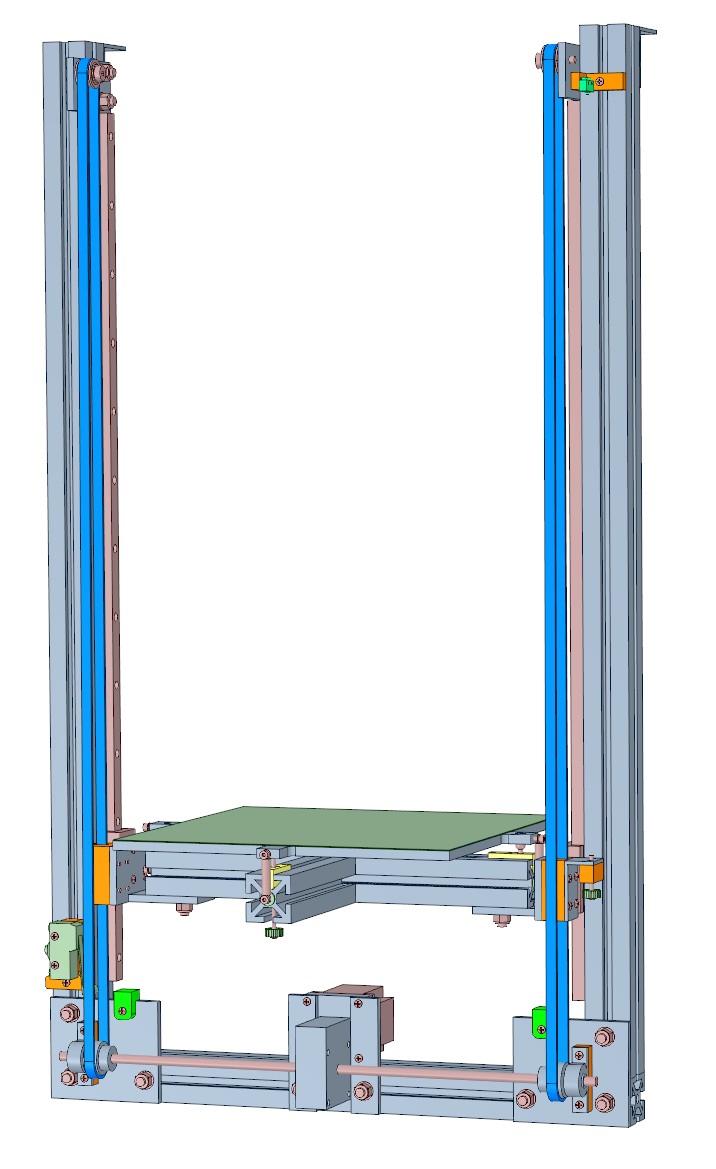

I use (practically) the same solution as Phaedrux, and can agree that the 3-leadscrew/1 stepper configuration works great. Whatever bed leveling problems I occasionally face are related to how my currently flimsy print bed is attached to the print gantry, not the leadscrews or stepper. If you look at the photos attached to this thing you can see the three leadscrew/1 stepper installation on my printer. Phaedrux uses the same system minus my extra idler pulley in front of the middle leadscrew. It's extremely stable and trouble free, and only requires one stepper.

-

@sethipus I also agree that with 3 screw is better, for exactly the reason you mentioned. Unfortunately, for now i can not invest into more hardware so i have to do with what i have, and that is 2x screws/MGN12 rails.

What i decided at the end is to go for a CL belt configuration as well with 1 motor driving the 2 screws.

Since two screws will only define a line, i will try to restrict any possible "rotation" on Y axis by designing the bed and Y axis mount brackets having this in mind.

Both your design and the one from Phaedrux look very neat and well designed. Next time i can invest more i will probably convert to 3 screws as well.

Thanks for the feedback!

-

@phaedrux said in Z axis design advice.:

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

Here's how you can keep two motors synced up and level the bed. I wouldn't use two motors without doing something like that.

I use 1 motor belted to 3 lead screws and that also works well.

So you only have the 3 lead screws and no guide rods/rails?

Frederick

-

@dkos You can do it with two linear guides, one motor, and no screws:

I used that design in my corexy printer, with some minor changes since I built the machine about 3 years ago. It has proven very stable- there's no autoleveling and I don't have to relevel the bed unless I take something apart for modification. The bed support is just a t-slot tee, and uses a three-screw kinematic leveling system that allows the heated bed to expand without forcing anything to lift or flex.

-

@mrehorstdmd I remember reading through some post in the reprap forum where i saw your design! I have to say i grew font of it. I can imagine that the linear rails have so little play that having two should be enough for a 3D printer heatbed. The belt system is interesting as well but as i understood without the worm gear with the 30:1 ratio (if i recall correctly) most probably the bed will fall down when powered off. Also, did you had any problems adjusting belt tension? Specifically in case the tension is not the same in both ends, say after many hours of use or belt stretching, maybe a minor misalignment can lead to binding?

Truth is, i did not consider that besides the worm-gear motor assembly in your design i have the hardware to implement the rest for the Z axis, which is very appealing to me. Although i would need to obtain somehow the ball shaped parts for the 3 screw kinematic leveling.

And last, the post explaining the changes you did over the year it is very interesting, thanks for sharing!

-

I've had no issues with the belts as far as unmatched tension goes. I did have a problem with the original belt clamp design when I was using steel core belts.

Quality linear guides have zero play in the bearing blocks.

The sphere headed leveling screws can be replaced with acorn nuts on regular screws, and then all the leveling adjustments can be made from below the bed.

I've seen other printers using home made worm gear boxes that use better gears than the set I tested. The owners say the Z axis print quality is fine. At some point I'll try one of the gear sets they use and see how it goes.

-

Good to know that you did not face any mismatch issues. I've read about the belt clamp in your post, i am using supposedly "fiber reinforced" belts.

My rails are not original Hiwin or equivalent quality, but they work quite well (i dont think zero play, but quite close) and i am happy with them for now (way better than the low quality linear rod/bearing system i ve had before).

Gathering all the ideas, I will adapt the 3 screw bed leveling on 2 lead-screw driven z axis. I will go with your suggestion (acorn nuts on regular screws, why didnt i think of that?! :P). For now, I will stay off the belt driven system until I am able to invest a bit more time/money on the worm gear assembly (or any equivalent gear reduction) to avoid the falling of the bed.

Thank you very much again for suggestions/ideas!