Hello everyone, I would not be surprised if the same question has been asked before, but I did not find an answer searching the forum so here it is:

Some background:

I followed this guide to set up my Dual independent Z:

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

Before, I was quite fond of the Manual bed leveling assistant, and I used the config as explained here:

https://duet3d.dozuki.com/Wiki/Using_the_manual_bed_levelling_assistant

Now the problem: when I was using the manual one, I had the 3 adjustment screws with the positions set via the M671 and I was probing as close as possible at each one of them. Then, I had the very nice console output on how much I should adjust each screw.

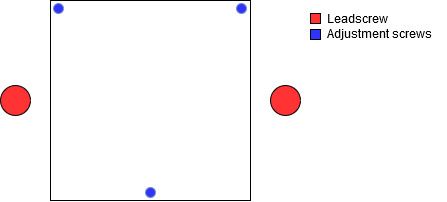

Converting to dual Z I had to change the M671 to define the position of each leadscrew. While that is perfect for the X axis (2 opposite leadscrews along that axis), and height difference is corrected by the motor automatically, this does not include the Y axis compensation.

As I understand, I can use the dual independent Z for X axis, and maybe the bed mesh compensation to account for the Y, but my question is:

Is it possible to define both the positions of the leadscrews and the adjustment screws differently, so i can get this nice console output while still using the dual Z.

I think of it like a sequence of probing close to the leadscrews -> motors adjusting ->probing close to adjustement screws->console output to adjust the screws. At the moment whenever I need to level the bed I am doing it by manually moving the head close the adjustment screws and checking the nozzle offset with a 0.1 feeler gauge.

Am i missing something?

P.S. I know from the theory that I need 3 points to define a plane, therefore I can have one point as reference and adjust the other 2 with the motors. For my system to work like this though, it will require mechanical changes that I can not implement at the moment.