M592 seems to have no effect on extrusion (in machine control)

-

M592 seems to have no effect if I test extrusion from the "Machine Control" tab.

If the following statement is true, I don't really know how to test it, because theoretically G1 E* will not work too?!Nonlinear extrusion is not applied to extruder-only movements such as retractions and filament loading.

-

Nonlinear extrusion is only applied to printing moves, i.e. moves that involve both XY movement and extrusion.

-

is there a way to test this without xy movement?

-

@dgrat said in M592 seems to have no effect on extrusion (in machine control):

is there a way to test this without xy movement?

No. If we applied nonlinear extrusion to extruder moves with no XY movement, it would mess up retraction distances and filament loading.

You can test M592 by doing a slow X and/or Y movement + extrusion, with the nozzle well clear of the bed. For example, if you do G1 X0 followed by G1 X100 E100 F300 then both X and E will move 100mm at 5mm/sec.

-

I been playing with M592 and did not get what I was expecting but think it should work. I will test print tomorrow and let you know if it helps.

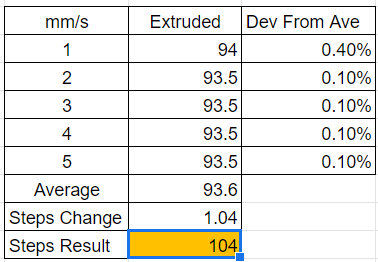

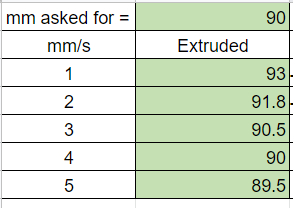

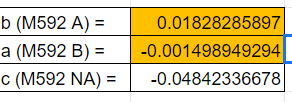

I made the program below to move XY and E and measured how much filament is pulled. I ran it without M592 to get the numbers for the spread sheet. I have used the spread sheet found in other threads and came up with M592 A.018 B-.0015. My printer is a ANET A8. I left the default steps/mm at E100 for the tests and turned presaure advance off.

PROGRAM:

M104 S240 ; set temperature

M98 P"homeall.g"

G1 Z25.0 F1500 ;Move the platform down 25mm

G1 X10 Y10 F1500

M204 S760 ;Acceleration

M572 D0 S0.0 ;Preasure Advance

M592 D0 A.0183 B-.0015

M109 S240 ; set temperature and wait for it to be reached

G21 ; set units to millimeters

G90 ; use absolute coordinates

M82 ; use absolute distances for extrusion

G92 E0

;1mm/s=60MM/MIN

;2mm/s=120MM/MIN

;3mm/s=180MM/MIN

;4mm/s=240MM/MIN

;5mm/s=300MM/MING1 X110 Y110 E90 F300

M104 S0 ;extruder heater off

M98 P"homex.g"

M84 ;steppers offWith M592 D0 A.0183 B-.0015 I get the following:

1mm/s = 94mm pulled

2mm/s = 93.5mm pulled

3mm/s =93.5mm pulled

4mm/s =93.5mm pulled

5mm/s =93.5mm pulledI expected M592 to get all feed rates closer to 90mm pulled. Any ideas why it did not do what I expected? I know I can change the steps per mm for E. Couldn't a formula be such that A and B would put the calibration to 90mm?

-

@Keith53 Non linear extrusion is to compensate for extruder slippage. So it can only increase the extrusion amount. You should calibrate the extruder steps per mm to give the correct feed rate at low speed.

-

Ok that makes sense. I was wondering why this was in the spread sheet and now I know.

Thanks