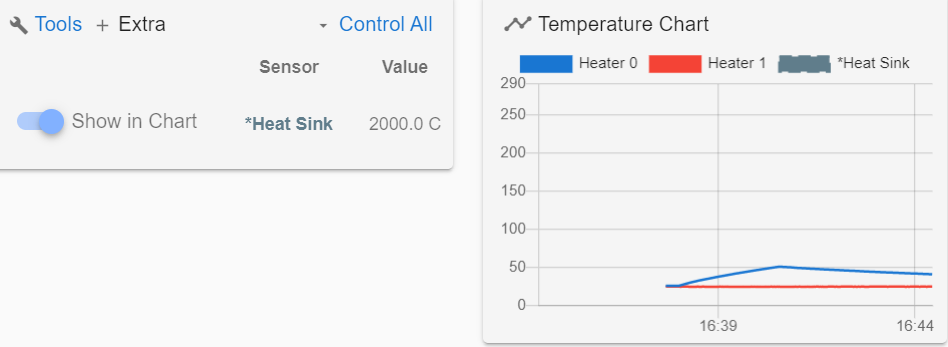

I changed it to M308 S2 P"e1temp" Y"thermistor" A"Heat Sink" and it works now. Wonder why E3D calls it a PT1000?

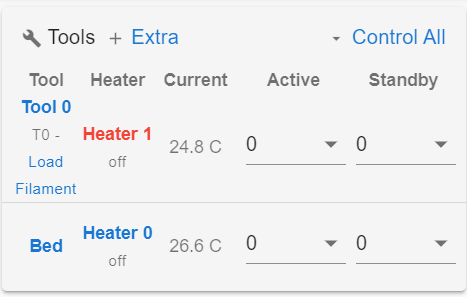

Is there a way to get it to show up with Tool 0 and Bed so I do not need to push the "Extra" button to see the temp?

I changed it to M308 S2 P"e1temp" Y"thermistor" A"Heat Sink" and it works now. Wonder why E3D calls it a PT1000?

Is there a way to get it to show up with Tool 0 and Bed so I do not need to push the "Extra" button to see the temp?

I checked the resistance and it is 95K at room temperature. It is plugged into the connector next to the heater block.

I add the line below but it looks like it is reading 2000C. How do I fix this?

M308 S2 P"e1temp" Y"pt1000" A"Heat Sink"

I am making an Extruder and want to use a PT1000 to measure heat creep in the heat sink with different fans/heat sink designs. IF I connect the PT1000 to E1 on the Duet board how do I change the config file so I can see all three temperatures, bed, extruder and heat sink?

Broad is a Duet 2 WIFI running 3.0 firmware.

From current config file:

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S275 ; set temperature limit for heater 1 to 275C

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

Ok that makes sense. I was wondering why this was in the spread sheet and now I know.

Thanks

I been playing with M592 and did not get what I was expecting but think it should work. I will test print tomorrow and let you know if it helps.

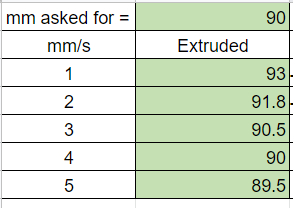

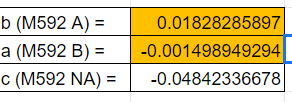

I made the program below to move XY and E and measured how much filament is pulled. I ran it without M592 to get the numbers for the spread sheet. I have used the spread sheet found in other threads and came up with M592 A.018 B-.0015. My printer is a ANET A8. I left the default steps/mm at E100 for the tests and turned presaure advance off.

PROGRAM:

M104 S240 ; set temperature

M98 P"homeall.g"

G1 Z25.0 F1500 ;Move the platform down 25mm

G1 X10 Y10 F1500

M204 S760 ;Acceleration

M572 D0 S0.0 ;Preasure Advance

M592 D0 A.0183 B-.0015

M109 S240 ; set temperature and wait for it to be reached

G21 ; set units to millimeters

G90 ; use absolute coordinates

M82 ; use absolute distances for extrusion

G92 E0

;1mm/s=60MM/MIN

;2mm/s=120MM/MIN

;3mm/s=180MM/MIN

;4mm/s=240MM/MIN

;5mm/s=300MM/MIN

G1 X110 Y110 E90 F300

M104 S0 ;extruder heater off

M98 P"homex.g"

M84 ;steppers off

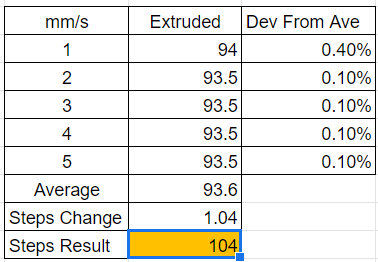

With M592 D0 A.0183 B-.0015 I get the following:

1mm/s = 94mm pulled

2mm/s = 93.5mm pulled

3mm/s =93.5mm pulled

4mm/s =93.5mm pulled

5mm/s =93.5mm pulled

I expected M592 to get all feed rates closer to 90mm pulled. Any ideas why it did not do what I expected? I know I can change the steps per mm for E. Couldn't a formula be such that A and B would put the calibration to 90mm?

@Phaedrux said in How to Set Z home:

Can you post your homing files? Maybe your full config.g too.

Do you mean that the nozzle is pushing into the bed surface? How are you measuring -0.3?

When you trigger the endstop the position is set to either the minima or maxima from M208. So triggering the zmin endstop should set the position to -0.3 as you have that as your minima. Unless it's being reset with an G92 Z after hitting the endstop.

The G92 Z0 was resetting it in the homeall.g and homez.g files. I commented out ;G92 Zxxx and now when it is on the Z end stop it shows what is in M208 below Thanks!

M208 X-33 Y-10 Z-0.3 S1

Not sure why G92 Z-.03 did not work. I use G92 on mills at work sounds like it should do the same thing on the printer.

G92 "Change Work Coordinate System"

G92 X0 Y0 Z=VTOFH[VTLCN]+12.7

This would set where the spindle is now to X0 Y0 and Z would be the current tool in the spindles length+12.7

I am using a switch to home XYZ. When I home Z the nozzle is about .3mm below the bed. I have been trying figure out how to set it so it knows this. When I home XY the web interface shows X-33 Y-10 but Z still shows Z0.0.

; Axis Limits

M208 X-33 Y-10 Z-0.3 S1 ; set axis minima

M208 X220 Y220 Z240 S0 ; set axis maxima

I also tried editing the homeZ.g and the homeall.g

G92 Z0.3 ; set Z position to axis minimum (you may want to adjust this)

What am I doing Wrong?

Thanks

How do I setup Cura to post the Fan on after the first layer? Cura is putting in M107 and M106 S255

I have the Duet2 Ethernet setup on my printer. I an now working on the start and end code to put in Cura. I am running the newest firmware 3.0. I have the Extruder fan plugged into FAN0 and part fan in FAN1.

The Extruder fan will turn on and off when the hot end reaches the set temp. I usually do not want the part fan to turn on until the first layer is finished. I know I could set T to a large number at the start but how do I get this setup so Cura will turn it on after the first layer?

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H T60 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T60 ; set fan 1 value. Thermostatic control is turned on