[not yet solved] Tevo Little Monster DuetWifi errors

-

There was a bug in the firmware whereby H parameters on G30 commands were ignored if deployprobe.g and retractprobe.g files were used, for example for BLTouch. This has been fixed in firmware 2.02RC5.

-

I ordered the extension volcano for the original D3D hotend. Both should arrive in this week .

I'll restart the calibration process after I assembled the new components. Don't want do the work twice. I bought also some copper nozzle. Ole! -

Dear absoluT...

I got it....

I made some further change at the setup I'll explain in an other post but some summing here:

-D3D original hotend + volcano extension as the original TLM. + copper nozzle (nickel coated)

-Changed belts with ones iron cored.

-Cartridge modified for a far better precision (with Teflon thickness + bi-adessive scotch) .

-Borosilicate custom made glass (x2) 41,5cmX5mm + 3 auto-build support for block the glass.

-The damn white glue really work! Moisture of 2/5 glue-water , I used just a sponge for apply it. Than the bed at 50 degree. The big piece doesn't move from the glass!Thanks to any one for the support...for sure I'll ask other stuffs...but right now I'll give back my contribution opening a new thread with my accomplishments.

I'll mark as solved the 3d. -

Hello,

I also have a Tevo Little Monster and I would like some help to understand what I badly parameterized to have this form of card in comparison to that of giostark.

I enclose you bed.g and config.g!

Thanks

bed.g

0_1549405330644_bed.gconfig.g

0_1549405365128_config.g -

That height map looks very good to me. Is there a problem?

-

Yes, it's the same printer as Giostark so why the map is not more circular as can be seen on the Giostark map above.

I am french and use googletrad and the tracduction of technical words to link to the impression are poorly translated. I still do not understand why my 1st layer is still so bad.

I can tinker with some modify G31 P25 X0 Y20 Z0.84 but it's perfect. I think that on the mechanical side the printer is well tuned but I must not understand something in the calibration procedure.I do not know what information to bring for help with my problems.

-

My guess is that you have a Z probe that is offset from the nozzle and you have a geometrical error that causes the effector tilt to vary with XY position. This causes the apparent trigger height of the Z probe to vary with XY position. It's possible to correct for this using H parameters on the G30 commands in bed.g, but tedious.

-

I will try to control all these points but it is not obvious to be precise. By the way, what is the order of magnitude XX.XXXmm?

When I do my calibrated to find the value G31 ZX and that I launch my impression I always 0.20mm too high. So I change the value of G31 Z0.687 + 0.20 to have a 1st layer that hangs and rotates between 0.25 and 0.35mm.

I controlled the distances between the top of the printer and a point of the carts that had different values. I now have about 4cm everywhere I will try to do this with the caliper.

But it did not really change the quality of my first layer (Nozzle 0.8mm)

L'imprimante

-

dc42

what should be changed as parts to solve this problem of geometry? -

Try this guide and join this TLM group, https://www.facebook.com/groups/TEVO.Monster.Delta.Owners/

-

I thank you, I will study with precision.

-

Hello,

I just control the angle of the towers and I do not have the same exactly the same value. This can be my geometry problem?

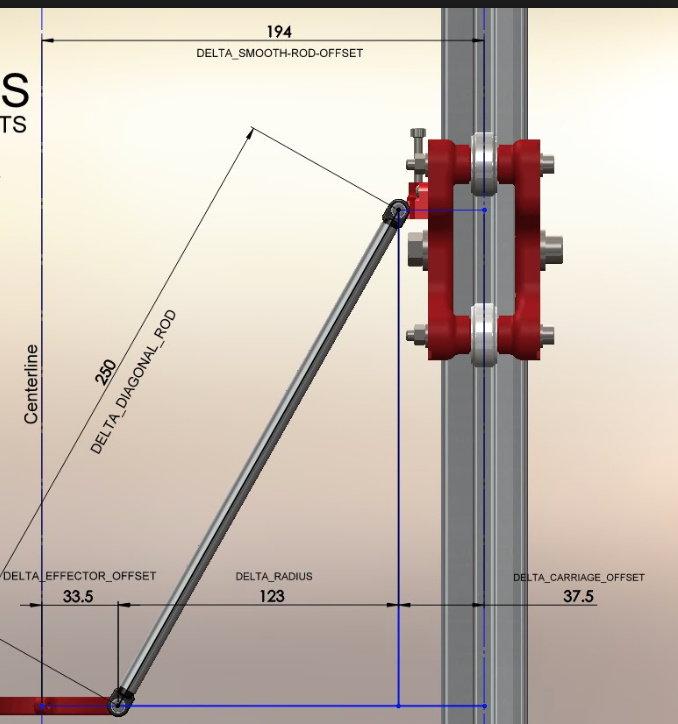

I will now control the length of my Delta Diagonal Rod -

Auto calibration will sort out the tower angles for you.

-

I think it would be complementary to bring illustrations and or videos to the Duet manual on the essential control points of a perfect machine calibration. Especially for the illiterate technicians like me.

-

I still do not understand the procedure of calibrating a delta with Duet but I will not give up. how to disable auto calibration? I think I can have a 1st more homogeneous without the self calibration. I checked everything manually and my tray with borosilicate glass is really flat.

-

My geometry problem may come from this problem (see video)

When I make a home and I go back 5mm to put out the leds of the endstops I always have an endstop that stays on.

I change endstop, screwed to racemess and unscrewed to lengthen the head of the screw, set the ten micro to have exactly the same distance between the three cart and the problem is the same, the led remains lit while the trolley is perfectly in front of the optical fork. When I push the cart slightly, the led goes out.Can you help me understand this problem?

https://www.icloud.com/iclouddrive/0od7VaaViYMMcV5_HiBiwm8dA#IMG_5224

-

Hello,

I have exactly the same problem as you.

I have an identical printer is impossible to turn off the limit switches, -

Tu es Français non?

Tu as une couche de hauteur homogène avec ta TLM?you have a 1st layer of uniform height with your TLM?

-

@rafb Paint the flags with something that IR doesn't go through. Many plastics are transparent to IR.

-

@rafb

Oui je suis bien Français...

Pour la 1er couche c'est pas trop mal à condition que je n'imprime pas quelque chose qui est une trop grande surface