Must pulley and idler sizes match?

-

When I started with 3D printing I read or heard somewhere that idler size does have to match the one of the pulley. I did not question this at that time.

Talking about a simple Cartesian where the pulley is just used to change direction of the belt.Yesterday I came across a blog post by E3D that they now also offer genuine Gates belts, pulleys and idlers. For pulleys they have various tooth counts but for idlers they only have 20T (or equivalently sized smooth idlers).

So I started to question this previous "rule" I had in my head. But the more I think about it the more I confuse myself.

Right now I am at a point where I think idler size does not matter since it is just a passive component rerouting the belt. But I could not explain why this would be true (or not).

So can please anyone help me out here? I'm going crazy on this one.

Also an example as part of the explanation would be much appreciated.

Also an example as part of the explanation would be much appreciated. -

@wilriker Quick answer - no they don't have to match. Longer answer - why should they have too? The only thing an idler does is change the direction of the belt path. As a general rule, idlers ought not to be too small in order to minimise the bend radius of the belt but that's the only criteria I can think of off hand.

-

@deckingman Thanks Ian! That's where I ended up, too. I think I just needed somebody to confirm.

I can't even remember where this "rule" came from. Not having this restriction makes much more sense.

-

The critical thing is that where a belt attaches to a carriage, the sections of belt leading into and out of the carriage must run parallel to the direction of motion. For example, if you have a length of belt running in the Z plane parallel to the X axis with a pulley at either end and a carriage in the middle, the pulleys at the two ends can have different diameters as long as their shafts have different offsets in the Y direction to allow for the different diameters. The rule "same size idlers as motor pulleys" would apply if the two pulley shafts were lined up with the same Y coordinate.

I hope this makes sense without a diagram.

-

@dc42 It took me a while to visualize this in my head (mainly because I mixed two different representations of XYZ

) but now I think I got it.

) but now I think I got it.That though means that I need to adjust how my Y belt is fixed to the bed carriage since the fixing point and the pulleys are on slightly different Z heights. That leads to the belt not being strictly parallel to the movement direction - even though I have equally sized pulley and idler.

Or I need to lower the bed carriage a few mm. -

@wilriker I guess one way to visualise it would be to think of a right angle triangle where the belts attach to a carriage. If the belt path forms a hypotenuse, then it's wrong.

-

@deckingman Now, that sent me back into confusion state again. So now it's diagram time.

In the following diagram I showed what I understood to be bad in the upper part and good in the lower part. Did I get this right? This is only regarding belt paths where the parts attach to the bed.

-

your lower picture is the right one the main thing to aim for is that the driving part of the Belt path needs to be a straight line and paralell to the axis being moved.

-

@dougal1957 Thanks for confirming.

Just to be totally sure I got it right this time another diagram with a totally crazy and exaggerated belt path. I believe it is still correct, isn't it?

P.S.: Only one of these is supposed to be driven by a motor.

-

@wilriker yes that's my understanding

-

@wilriker said in Must pulley and idler sizes match?:

@dougal1957 Thanks for confirming.

Just to be totally sure I got it right this time another diagram with a totally crazy and exaggerated belt path. I believe it is still correct, isn't it?

P.S.: Only one of these is supposed to be driven by a motor.

Yes, that's what i was trying to convey.

-

Hello,

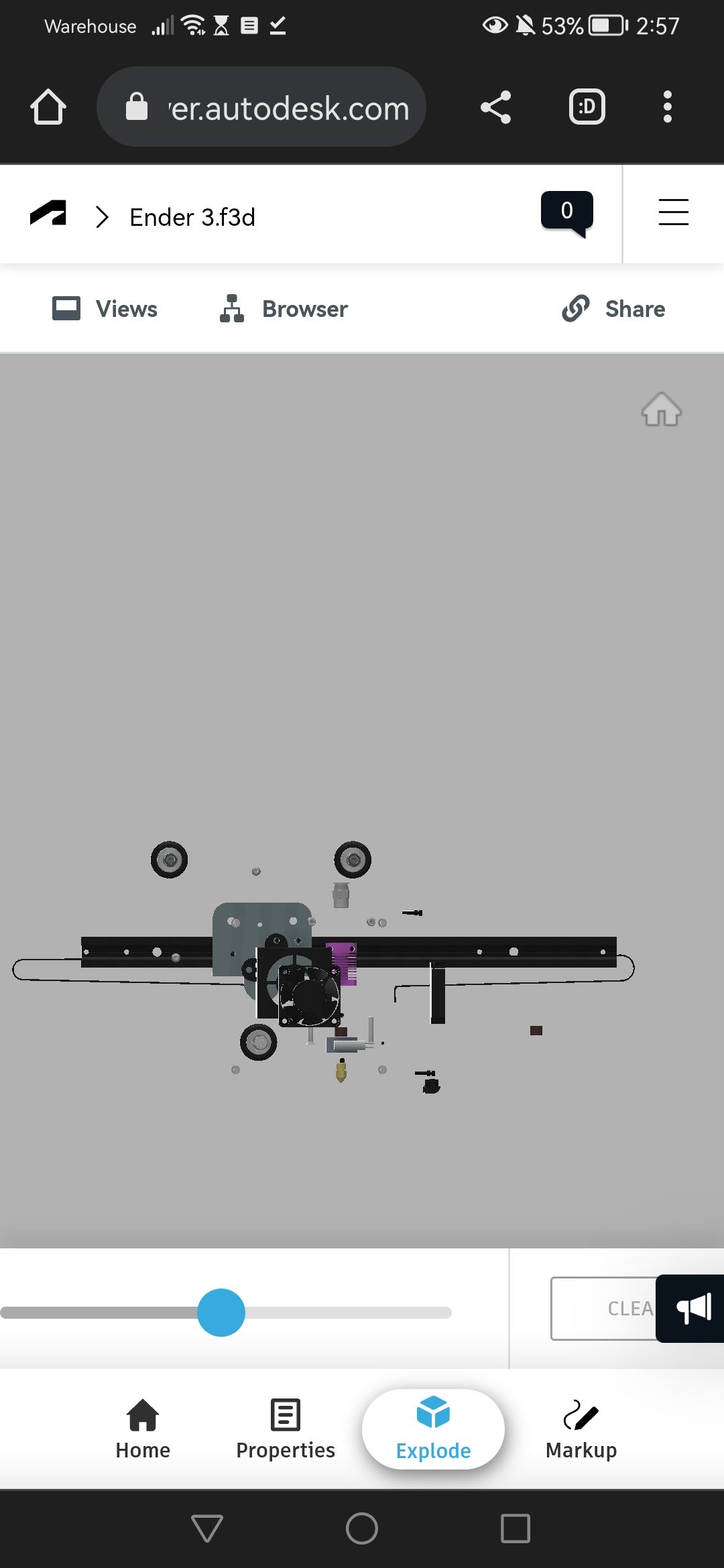

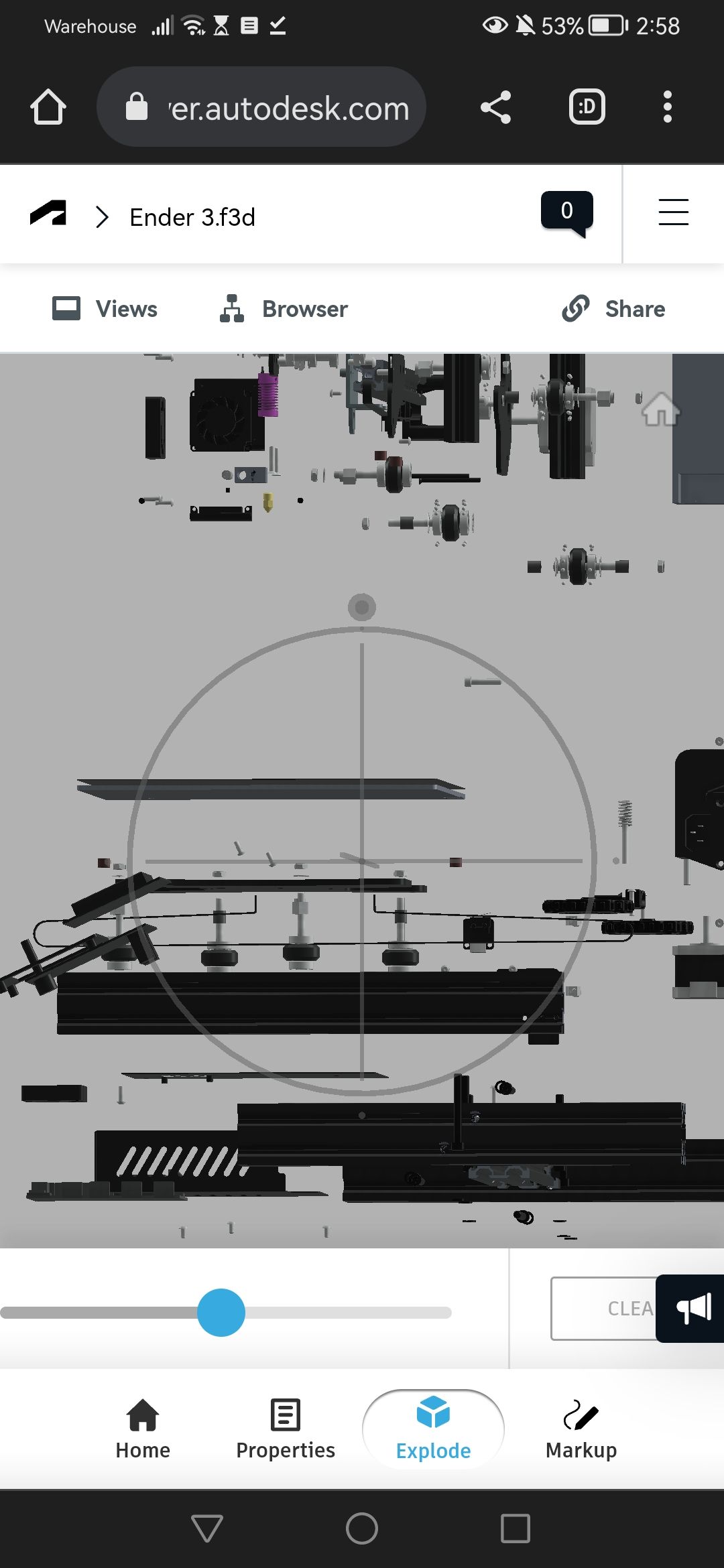

I am not a duet user, but I came across this thread while thinking the same thing. Discovered my ender 3, for all belts, have different sized pulleys and idlers to my surprise. I had always thought they were the same size and thus the belts always parallel to the axis. Not only that, the more I thought about it I came to the same conclusion as you here did, so long as the carriage belts are parallel ur fine. But if they are not, then you will have slightly less motion than desired right? Well shucks the ender 3 design did not seem to think of this at all!

And yet, I still got dimensionally accurate prints. So I assume the difference must be negligible. However it is strange that no one has noticed as far as I can tell. Sorry for grave digging

[alt text]([link text](

))

)) -

@PassiveAggressor On a Cartesian, the sections of belt connected to the gantry and bed must be parallel to the axis, but other sections don't matter. If you think about it, 1 revolution of the motor, using a 20 tooth pulley will move the belt 40mm so it doesn't much matter where the motor is, as long as the belt is parallel to the axis between the idlers at either end of that axis.

-

Some people like to use the toothed idlers. The problem with them is the bearings are tiny and have limited life, and the shafts have to be very small diameter- i.e. flexible. On the plus side, moving mass is relatively low.

If you eliminate the toothed part of the pulley and simply use the smooth surface of a bearing, you can maximize the bearing size/life.

I read a Gates white paper on GT2 belts (that I have lost track of) stating that when using smooth idler pulleys in contact with belt teeth, at least 9 teeth should contact the pulley. In corexy, the belts bend 90 degrees around the idlers (unless you do something extra with the belt path). That implies that the circumference of the pulleys should be large enough to contact 36 teeth. 36 teeth with 2 mm spacing implies 72 mm circumference. That translates to diameter of 22.9 mm. I used F608 skate wheel bearings for pulleys (22 mm diameter) and they don't create any toothy artifacts in the prints. The large size of the bearings means they will last a long time in the printer, and the large diameter axle (8mm) won't flex.

If you're wrapping the belt 180 degrees around the pulley, the diameter can be smaller- 11.5 mm. 685 bearings are 11 mm in diameter and should work fine. 685's fit a 5mm shaft.

F608 bearings are heavy, as are the 8mm axles, both of which add to the moving mass, so if you're trying to build a superfast printer, you may want to stick with the smaller, lower mass options and be prepared to replace them periodically.

-

@PassiveAggressor your observation is correct and its known that the ender3 belt path is less than ideal. But as you found, at that particular size and setup, the deflection from a non-ideal belt path is negligible enough. Any random ender3 has a higher chance of any of its other design ... decisions to affect print quality and dimensionality.

-

@mrehorstdmd hey Mr Rehorst? Say those idlers you talked about, for 20 teeth the diameter is given as 12 to 12.15, but 20 teeth gives a length of 40mm, 40/3.14 is 12.74, am I wrong about this or are they accounting for something I m unaware of. Also thanks guys for replying I forgot about this until I was googling what the diameter of idlers should be and this came up again aha

-

@PassiveAggressor Toothed idlers can be smaller than plain idlers. That's why I suggested that if you're trying to minimize mass/maximize speed, using the toothed idlers with the tiny bearings is going to be a better option, though you may have to replace them periodically because the bearings may fail, especially if they are the cheapo stuff typically sold to printer hobbyists. Filastruder sells Gates pulleys that probably use better quality bearings than the stuff you get from AliExpress. Gates pulleys seem to be drilled better than the cheap stuff and they only cost about $5 each.

The small, plain idlers sold to printer hobbyists are too small to use in contact with the belt's teeth, except for a 180 degree wrap. If you want to use those in a corexy machine with 90 degree bend in the belt, it's probably best to put a twist in the belt so you can run the smooth back side of the belt on the idler. That will prevent belt tooth induced print artifacts.

The nominal 2mm spacing between the teeth of the belt becomes smaller when the belt wraps around the pulley, so in my example of using 22 mm dia 608 bearings, even though the diameter is a little smaller than the 22.9 diameter calculated to put 9 teeth in contact with the pulley surface, the tooth spacing will be smaller than 2 mm, so you'll actually get 10 teeth in contact with the pulley surface with a 90 degree bend over a 608 bearing.

There's another consideration when it comes to high speed operation- noise. I built a couple servomotor driven corexy sand tables and worked hard to keep speed high and noise low. I found that when you get to about 200mm/sec every pulley (smooth or toothed) the belt teeth touch makes audible zipping noises, and the faster you go, the louder it gets. In a corexy mechanism, that's at least 10 zippers and a lot of noise. I put twists in the belts and run the back sides on smooth pulleys made from 625 bearings and they run quietly, even at high speeds (typically 500-1500 mm/sec). The drive pulleys still make the zipping noises, but that seems unavoidable as long as you use toothed belts.

-

@mrehorstdmd Mark, just for info, when the automotive industry changed from chain driven camshafts to belt driven ones it was found that having the tension too high would cause the belts to "whine" or "scream". It would be reasonable to assume the same would be true with our printers. So slackening the belts might make them quieter (although there are other reasons why one might not want to do that).

-

@mrehorstdmd wait but what's the theory behind the shrinkage? I would have thought it the opposite, that distance would stretch rather than shrink.

Also, what do u say as for using screws to hold bearings or idlers? The actual diameter of an M5 SCREW is not 5mm

-

@PassiveAggressor Let's say you are wrapping the tooth side of a belt around a 22 mm dia 608 bearing. Also assume the belt is 1.7 mm thick (a typical value). The outside diameter of the belt wrapped around the pulley is then 22 + 1.7 + 1.7 = 25.4 mm That means a complete wrap would have 25.4 * pi/ 2= 39.89 teeth touching the pulley. A 90 degree bend/wrap like you'd have for most corexy pulleys, would put 39.89/4= 9.97 teeth in contact with the pulley.

If you want to find the minimum pulley diameter that will have at least 9 teeth in contact with the pulley on a 90 degree bend/wrap, there will be 36 teeth in a full wrap. That's 36 x 2= 72mm circumference measuring the smooth side of the belt. That implies a belt + pulley diameter of 72/pi=22.9 mm. But the belt adds 3.4 mm to the diameter so the pulley diameter will be 22.9-3.4= 19.5mm

When you bend the belt toward the tooth side, the teeth get closer together. If you bend the belt the other way the teeth get farther apart.

The best thing to use to mount bearings is a shoulder bolt. They have accurately ground shaft diameters.