@mrehorstdmd sorry one more question, why do toothed idlers and untoothed idlers have the same outer diameter? Shouldn't toothed idlers be slightly bigger in diameter because they have teeth that mesh the teeth?

Latest posts made by PassiveAggressor

-

RE: Must pulley and idler sizes match?posted in 3D Printing General Chat

-

RE: Must pulley and idler sizes match?posted in 3D Printing General Chat

@mrehorstdmd yes I have read your blog some bit, useful stuff. I only regarded belt as zero thickness in relation to spacing of the teeth on the idler

-

RE: Must pulley and idler sizes match?posted in 3D Printing General Chat

@mrehorstdmd ah I see. In the midpoint of the belt there is no stretching. But because the belt has thickness on either side of it, teeth get closer and teeth get further I see now

-

RE: Must pulley and idler sizes match?posted in 3D Printing General Chat

@mrehorstdmd thank you for replying. I think I get it but I gotta process it and visualise it. I guess I'm thinking about assuming the thickness of the belt is zero

-

RE: Must pulley and idler sizes match?posted in 3D Printing General Chat

@mrehorstdmd wait but what's the theory behind the shrinkage? I would have thought it the opposite, that distance would stretch rather than shrink.

Also, what do u say as for using screws to hold bearings or idlers? The actual diameter of an M5 SCREW is not 5mm

-

RE: Must pulley and idler sizes match?posted in 3D Printing General Chat

@mrehorstdmd hey Mr Rehorst? Say those idlers you talked about, for 20 teeth the diameter is given as 12 to 12.15, but 20 teeth gives a length of 40mm, 40/3.14 is 12.74, am I wrong about this or are they accounting for something I m unaware of. Also thanks guys for replying I forgot about this until I was googling what the diameter of idlers should be and this came up again aha

-

RE: Must pulley and idler sizes match?posted in 3D Printing General Chat

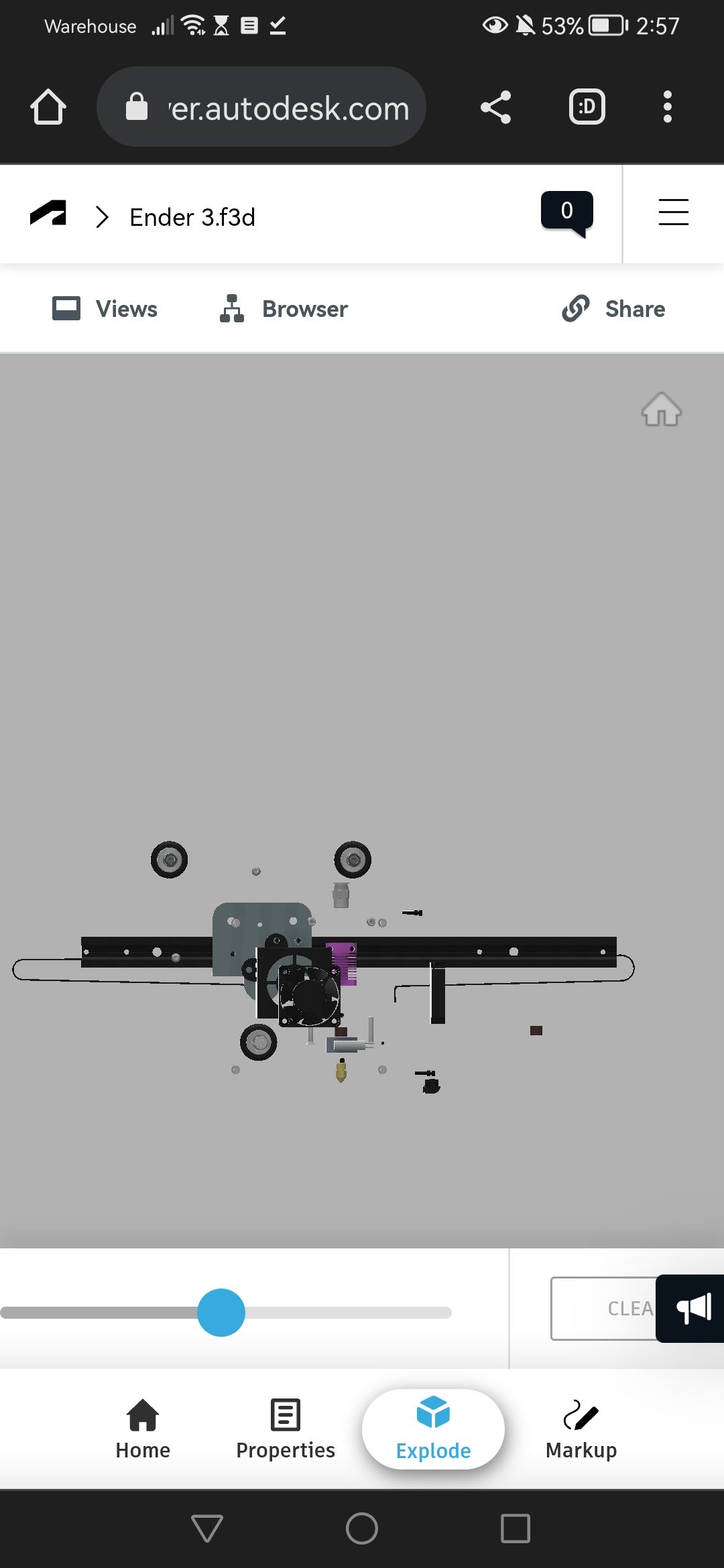

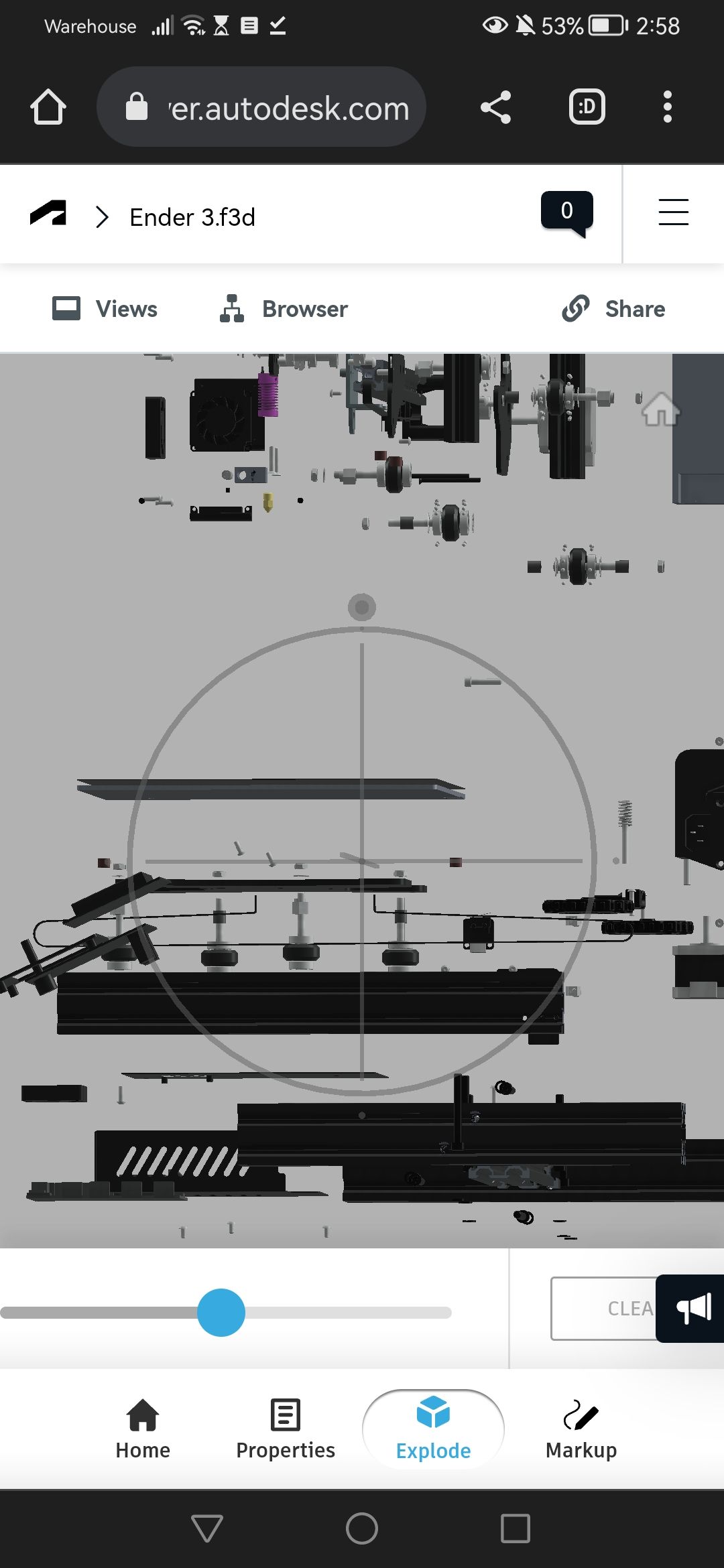

Hello,

I am not a duet user, but I came across this thread while thinking the same thing. Discovered my ender 3, for all belts, have different sized pulleys and idlers to my surprise. I had always thought they were the same size and thus the belts always parallel to the axis. Not only that, the more I thought about it I came to the same conclusion as you here did, so long as the carriage belts are parallel ur fine. But if they are not, then you will have slightly less motion than desired right? Well shucks the ender 3 design did not seem to think of this at all!

And yet, I still got dimensionally accurate prints. So I assume the difference must be negligible. However it is strange that no one has noticed as far as I can tell. Sorry for grave digging

[alt text]([link text](

))

))