New CoreXY 400x400x560mm Build in Progress

-

200$ sounds about right for a large plate of that size with tight tolerances.

One note with regards to your intention of using stall detection for homing on all axis. Don't do it. Your planned setup checks all the boxes for it to not work reliably. CoreXY is tricky because of two motors working at the same time. And on the Z axis you'll likely end up using some gearing between the motor and lead screws to increase torque. This will make it hard to tune the stall detection limit. The repeatability will also vary with motor tempm which can become maddening.

It will be far easier and reliable to just use simple switches. And on the Z axis having a probe to get a height map to verify the flatness and do compensation if necessary will be almost necessary given the large size of the bed and unknown tolerances.

Given the size of your build area I would recommend going with the volcano and a larger nozzle since if you're planning on printing large things you probably don't want them to take forever.

The Titan Aero is a great performing compact direct drive extruder, but it is also a tad finicky. Do a search on this forum to get a sense of what I mean.

But that's just my take on it. Your build is looking great so far. Can't wait to see how it progresses.

-

@phaedrux said in New CoreXY 400x400x560mm Build in Progress:

200$ sounds about right for a large plate of that size with tight tolerances.

One note with regards to your intention of using stall detection for homing on all axis. Don't do it. Your planned setup checks all the boxes for it to not work reliably. CoreXY is tricky because of two motors working at the same time. And on the Z axis you'll likely end up using some gearing between the motor and lead screws to increase torque. This will make it hard to tune the stall detection limit. The repeatability will also vary with motor tempm which can become maddening.

It will be far easier and reliable to just use simple switches. And on the Z axis having a probe to get a height map to verify the flatness and do compensation if necessary will be almost necessary given the large size of the bed and unknown tolerances.

Given the size of your build area I would recommend going with the volcano and a larger nozzle since if you're planning on printing large things you probably don't want them to take forever.

The Titan Aero is a great performing compact direct drive extruder, but it is also a tad finicky. Do a search on this forum to get a sense of what I mean.

But that's just my take on it. Your build is looking great so far. Can't wait to see how it progresses.

Interesting take on homing with the stall detection. Even if I decide to home X and Y axis one at a time?

Z axis I am willing to give it a shot, I have been following the stall detection on a few threads and seems that once it is dialed right, the repeat ability is well within reason to use it. But I could run into issues using 3 lead screws and a heavy build platform. Worst Case I could try to setup a 3 - endstop system to level the bed and hope to never need mesh leveling.

We just got in the Raise3D Pro2 Plus and it comes with a pre-calibrated build plate and does not have a probe. So it is possible, but I am not sure if it is doable.

Thanks!

-

@fickert I didn't have great success with stall detection on the Z axis with 3x 1mm pitch lead screws and a single 1.8 deg motor with 1:1 gearing, but you may have better luck with your setup. To help improve the resolution of the stall I switched to 0.9 deg motor but ended up losing too much torque to reliably lift my heavy bed platform. So I switched to 2:1 gearing, which got me more torque, but now made the sensitivity too weird and would seem to swing wildly with motor temp. In the end I switched back to the 1.8 deg motor, kept the 2:1 gearing and gave up on stall detection and use a BLTouch instead.

Even on a very flat plate you can find some warping. You won't know how it will turn out until you try and print on it.

Regardless, I think it would be something to setup after everything is already up and running as an improvement since the setup and tuning and testing is very time consuming and will likely involve a few head crashes.

Stall detection as endstop on X and Y in a CoreXY has been done (do a search to see what others have gone through to get there), but it is highly dependent on the motor.

I don't mean to sound down on stall detection as an endstop. It can be made to work, but when a simple switch is so cheap and reliable it's hard to see why you'd want to use anything else. Either way, stall detection while printing is totally separate and can work quite well, though it is still subject to the same motor sensitivity requirements, so your mileage may vary.

-

This post is deleted! -

Quick update, got the two front lead screws installed. The KP08's for the rear lead screw are still in transit, but that rear lead screw does not need cut down. The front two needed cut to 575mm to slip into place. Sadly I forgot to loop in my closed loop gt2 belt so I will need to uninstall them just to get the belt in there.

Hoping to finish machining the Carriage Idlers and finish the rear idler design to print by next Monday.

-

A few comments...

-

you checked bed flatness against your granite slab by slipping a feeler gauge under the edge of the plate while it sat on the slab. Was the protective plastic peeled off the side of the plate that was on the granite? By laying it on the granite, you "fully supported" the plate which is not what you'll be doing in your printer, so your measurement doesn't account for sag in the plate when it's supported by 3 levelers. If you really want to measure it in a meaningful way, put the plate on the bed support in the printer, tram it, and mount a gauge on the extruder carriage. Sweep the gauge over the surface and see what sort of range you get. That measurement will take into account sag in the X and Y axes, sag in the bed, thickness variations in the print surface, etc., all of which will determine whether you're going to get the first print layer to stick.

-

2020 extrusions seems pretty light duty to me for a printer this size. The machine is going to be throwing the X axis back and forth at pretty high speeds/accelerations and you can expect there to be some fore/aft movement in the frame. Bolting on rigid side panels should help. This matters because at the start of the print the bed will tend to move back and forth with the printer's frame, but as the print gets taller and the bed moves down, it will move less, so the print will move less, and the print quality may degrade.

-

The 9 mm X axis guide rail will be light, but over the long span you may have problems with it sagging or wobbling when you start and stop motion in the Y direction.

-

The extruder stepper needs to have enough torque to push the filament. You can find lots of tiny steppers, but without adequate torque, your light weight extruder won't work. If you gear the motor down to multiply torque, you limit speed. Light weight and speed are overrated. Even if you get the mechanism to move at 500 mm/sec, the extruder (any extruder) won't be able to deliver the molten plastic the way you want. My printer, UMMD, is not designed to be particularly light weight, yet I have been able to run it with acceleration at 10k and speed at 200 mm/sec. The X axis weighs about 1.5 kg. It did a fair job of printing, but how often is a fair job good enough? The faster it runs, the more it shakes and the noisier it gets.

-

It's not a big deal, but you shouldn't need antibacklash nuts on the Z axis screws. Gravity will keep the nuts firmly engaged with the screw threads at all times. Antibacklash nuts increase friction which may require more torque from the Z axis motor, especially since you're turning 3 screws with one motor.

-

If you enclose the machine you might be able to print ABS and other plastics that are more useful than PLA. An enclosure will also help contain the particles released when printing.

-

-

Thank you for getting to review my build.

I want to at least clear up what I can and hopefully pick at your brain a bit more.

-

the aluminum bed was measured on a granite slab, and the film was removed. I even deburred the edges to be sure no aluminum burr was left behind when they cut it (wasn't much if at all, but did it to be safe). I think your perspective on the plate goes for the whole assembly, as I can't recall now, but the be spanning 4 points in the corners it sags very little. Enough to disregard it, I can run it though simulation again in SW to confirm that. Partly why I went with 1/4in thick plate.

On another note that did give me a good idea, I should assemble the 2020 extrusion bed ontop the granite block to confirm it has complete flatness. -

I have wondered if the 2020 would be too little for this build, I pretty much just based it off of the FT-5 design, assuming it was enough. I didn't think about it like you mentioned when the bed moves downward and the bed quits moving with the frame. I will be enclosing the printer eventually, hopefully can reuse the enclosure from my FT-5. If not then I will get some alumium corner braces.

-

The 9mm rail is a concern for my I agree, and I still have an issue with it, BUT I am wanting to see how much of an issue. I probably should tackle it now, but am willing to see what I will be sacrificing. Maybe I am too knuckle-headed to changed my design at this time.

-

I check the stepper motor with a titan aero and it can extrude up to 20mm/s and still can retract 40mm/s so I believe it will be fine, but we will see. I don't see anyone doing it and so I wanted to pioneer a bit. If I steer away from the titan, than yes I will for sure have to ditch the stepper.

-

Thats a good thought. I just put them in there as habit, I have always been told to use them. But I see your logic, and with this weight of this build platform I doubt it will move, even with a z-hop. Especially if I try to use stall homing.

Again thanks for coming over to help me out, I realize now I was mainly focused on your build using the sqare aluminum tubing, I thought it was genius, but kinda missed all the extra rigidy you did to the frame.

-

-

I didn't see the XY stage in the CAD model, so it seems like you're working from the outside in. You may find that the XY mechanism that will fit in the space you've allowed for it won't reach you print envelope goal. When you have a print size goal, it's better to start by designing the mechanism, then build the enclosure around it.

If your goal to to minimize moving mass, using the F608 bearings I used may not be optimal. Those bearings are heavy, and have 8mm bore, so their axles are heavy, too. If you look around you might be able to find plastic or aluminum flanged pulleys that use smaller bearings and smaller axle hardware, while maintaining the relatively large diameter. A lot of printers use smaller diameter pulleys and seem to have adequate belt life and print quality.

Those tiny corner brackets don't really do much for rigidity compared to putting a sheet of plywood (ugh) or polycarbonate on the sides of the printer.

You might want to put leveling feet on the bottom of the machine. If the machine sits on an uneven surface the frame will twist to conform to that surface, especially if the machine is heavy. That twisting will distort the XY plane and could make it hard to tram the bed. UMMD usually sits on uneven concrete floors. When I move it to a new location I push on the frame and see if it rocks a little and if it does (almost always) I adjust the leveling feet to minimize the rocking.

UMMD's frame would have been a lot more rigid if I had screwed PC sheets for the side walls instead of fitting the dual layer PC into the frame's slots. I wasn't too concerned about rigidity (the 4040 extrusion is pretty good) and was more concerned with thermal insulation and appearance (I take it to makerfaires, etc).

-

I'll toss in a few comments here based on my build of Black Beauty (which @mrehorstdmd gave me some ideas on as well)...

You will indeed need some sort of bracing on the frame but the standard corner brackets will not be enough considering the lengths of the extrusions.

An enclosure would be good but I found that having a permanent enclosure double as both thermal control and frame rigidity meant that you could only access the print surface from the front where you'd have a door. With a small bed, this isn't an issue but with a large bed it's pretty convenient to be able to reach in from any side or at least the left and right but then you'd then need side doors that have fixed frames to act as the brace.

You could do the diagonal braces as @Stephen6309 suggested but they'd need to create a triangle with at least 100mm on each side.

Another option is to use pieces of 20mmx40mm extrusion set a little ways up from the bottom and down from the top with the 40mm face being vertical. That will give you more mating surface and be less intrusive than diagonal bracing. You could even add another 3 pieces on the sides and back midway to get even more support.

With either the braces or the extra horizontal members you can do anything with the enclosure you want since it's not load bearing.

A big +1 on @Phaedrux 's recommendation of the Volcano.

-

@mrehorstdmd said in New CoreXY 400x400x560mm Build in Progress:

I didn't see the XY stage in the CAD model, so it seems like you're working from the outside in. You may find that the XY mechanism that will fit in the space you've allowed for it won't reach you print envelope goal. When you have a print size goal, it's better to start by designing the mechanism, then build the enclosure around it.

If your goal to to minimize moving mass, using the F608 bearings I used may not be optimal. Those bearings are heavy, and have 8mm bore, so their axles are heavy, too. If you look around you might be able to find plastic or aluminum flanged pulleys that use smaller bearings and smaller axle hardware, while maintaining the relatively large diameter. A lot of printers use smaller diameter pulleys and seem to have adequate belt life and print quality.

Those tiny corner brackets don't really do much for rigidity compared to putting a sheet of plywood (ugh) or polycarbonate on the sides of the printer.

You might want to put leveling feet on the bottom of the machine. If the machine sits on an uneven surface the frame will twist to conform to that surface, especially if the machine is heavy. That twisting will distort the XY plane and could make it hard to tram the bed. UMMD usually sits on uneven concrete floors. When I move it to a new location I push on the frame and see if it rocks a little and if it does (almost always) I adjust the leveling feet to minimize the rocking.

UMMD's frame would have been a lot more rigid if I had screwed PC sheets for the side walls instead of fitting the dual layer PC into the frame's slots. I wasn't too concerned about rigidity (the 4040 extrusion is pretty good) and was more concerned with thermal insulation and appearance (I take it to makerfaires, etc).

Indeed the CoreXY is not in the model for the time being, but I do have a pretty good idea of what it will come out to be as for size and travel of the gantry. As for the corners I am still planning on either getting corner braces (aluminum or printing Carbon Fiber PC) as well as enclosing the printer once I have it up and running with PC as well. Just something not on the to-do list for the time being. Once I begin to dismantle the FT-5, I will have a decent supply of excess extrusions so as for reinforcing, that is when I will probably add them.

I am seeing now though this is really the first stab I have had at designing a printer from the ground up, and I really appreciate the input from everyone so please keep it coming

Seeing a few things I can improve on, and others I will just wait to see the outcome.

Seeing a few things I can improve on, and others I will just wait to see the outcome. -

Have you considered a zesty nimble for remote direct drive extruder to lower your carriage mass? You could add a duex board and then drive all 3 z screws independently for auto leveling.

-

@mikebridge said in New CoreXY 400x400x560mm Build in Progress:

Have you considered a zesty nimble for remote direct drive extruder to lower your carriage mass? You could add a duex board and then drive all 3 z screws independently for auto leveling.

Mike,

I will say I am not entirely sure of what you're talking about, Ha!

Just looking around for it, I never new there was such a thing lol. I will try to stick with my direct drive for now as the gantry design is pretty much done. But I will definitely keep this unit in mind in case I have to move away.

As for auto leveling with each lead screw this is something I also thought about, but didn't deem it necessary. Plus I would lose roughly 50-60mm of usable z height.

-

@fickert said in New CoreXY 400x400x560mm Build in Progress:

As for auto leveling with each lead screw this is something I also thought about, but didn't deem it necessary. Plus I would lose roughly 50-60mm of usable z height.

I haven't found need for auto-leveling on my XY machine. It only takes a minute or two to do it by hand and it doesn't need to be done again for quite some time.

Frederick

-

@fcwilt said in New CoreXY 400x400x560mm Build in Progress:

@fickert said in New CoreXY 400x400x560mm Build in Progress:

As for auto leveling with each lead screw this is something I also thought about, but didn't deem it necessary. Plus I would lose roughly 50-60mm of usable z height.

I haven't found need for auto-leveling on my XY machine. It only takes a minute or two to do it by hand and it doesn't need to be done again for quite some time.

Frederick

I have 2 of the 3 leadscrews currently installed. While being guided by linear rails, there is very little slop, so I assume if I cannot get stall homing to work on the z-axis then I will not be that sad. I agree this will hopefully not need much leveling in general.

-

@fickert said in New CoreXY 400x400x560mm Build in Progress:

@stephen6309 said in New CoreXY 400x400x560mm Build in Progress:

@fickert You may want to put some diagonal bracing on the side to keep the printer from twisting. On my corexy i made, I drilled access holes and tapped the extrusion ends to screw them together to not use any angle brackets.

I did think about this. Probably not a bad call at all. I was even thinking of doing some diagnal cable bracing as an alternative. Similar to pull barn structuring. Figure it's something I can add down the line.

I was wondering if you considered building an enclosure?

It would help for printing specific materials, strengthen your frame and keep it from bending and twisting. -

I apologize for anyone that has stumbled upon this and saw there was no conclusion.

This printer has been fully operational at the start of the 2019 year.

We bought a home and moved in late Dec. 2018.

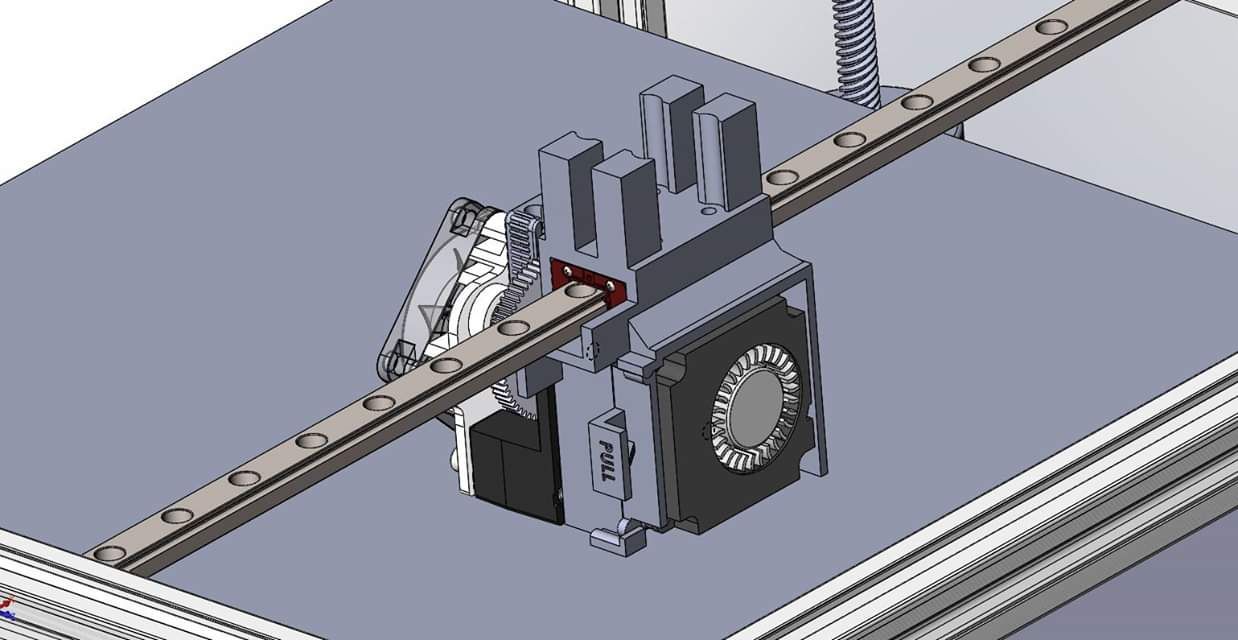

We bought a home and moved in late Dec. 2018.I attached a few photos of the full setup. Ignore the extra long shoulder screws on the carriages, I had these lying around and they work great!

I have been printing a bunch of poly-carbonate for a few projects from friends of mine (Porsche intake system, and mounting components)

Also the spine is 24 inches long

-

One thing I still really would like to do is mill and tap the joints at the ends and cut 45 degree 100-150mm extrusions for the corners.

-

@Fickert Looks good.