Precision Piezo Andromeda

-

I checked the website this time before asking:

How thick is it when mounted in a resting (non-flexed) state? In other words, how much space should be allowed in a designed mount?

Also, when multiples are wired to a piezo20, should they be wired in parallel?

Finally, what is the diameter of the center hole?

-

I have these, I am using 4 of them for under-bed sensing.

They are wired in parallel to a V2 Piezo board. My mount setup most closely resembles the rightmost of the examples, though I have no spring.

the thumbwheels hold a captive nut and fit snugly between the aluminum square tube and the Andromeda board. The square tube is mounted firmly to the bed carriage with the heated bed screws going through the tube and thumbwheels. Pressure anywhere on the bed is transmitted to the Andromeda board, and triggers the Piezo probe.

I have had good success, and I have noticed that the Z probe seldom triggers during printing, so it's false signal rejection is excellent. I have the Z probe offset set to 0.06mm, so its sensitivity is also very good. Repeatability is good across most of the bed, though it does reduce a little when probing outside of the square defined by the mounting screws. (You can see in the photo that there is a little bit of printable area outside of that square.) Within the defined square, probing is consistent. I found these to be a far superior solution to my previous set-up with the piezo discs mounted in the bed bearing mounts.

All this said, I do believe that a hot-end probe is a better solution, if you are able. Any under-bed solution is prone to inconsistency in some cases (In my case, probing outside of the square defined by the mount points.) There will also be unavoidable differences in physical response properties when more than one sensor is involved, and a potential for differences in pre-load on the sensors, unless you are extremely careful when setting things up.

-

The PCB itself is roughly 1.7mm thick but where the connector is soldered on is 5.5mm thick.

Yes they should be wired in parallel, there's another set of holes opposite the connector so they could be daisychained if needed.

The centre hole is 3.2mm just like the others.

Idris

-

@supraguy said in Precision Piezo Andromeda:

I have these, I am using 4 of them for under-bed sensing.

...

the thumbwheels hold a captive nut and fit snugly between the aluminum square tube and the Andromeda board. The square tube is mounted firmly to the bed carriage with the heated bed screws going through the tube and thumbwheels.I'm having a hard time visualizing what you described. Can you please post a picture showing the piezo board mounted and everything attached?

Thank you

Gary -

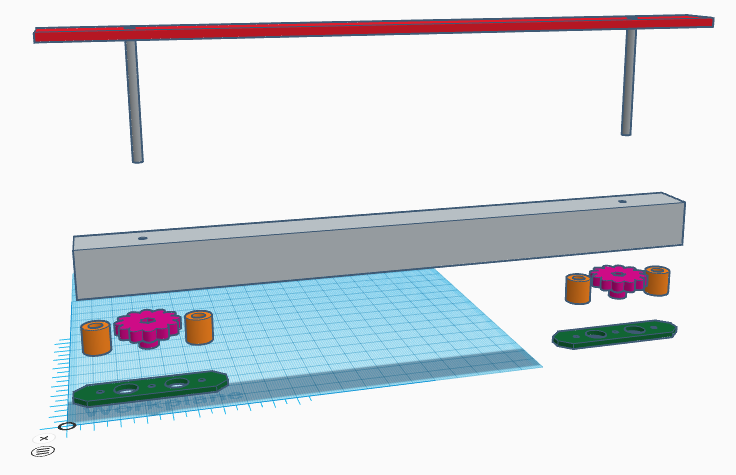

I don't have a photo installed, but this is a Tinkercad rendering of the mount. (I'm at work at the moment, and can't just snap one.)I used 10mm stand-offs instead of the orange spacers for the actual production, and the square tube is screwed to the Y axis plate

Maybe the exploded view will be a bit clearer. Because the thumbwheel is the same height as the stand-offs, it fits snugly between the Andromeda board and the aluminum tube, with no space to move. this holds the build plate stable in height and allows it to transmit any force on the build plat down to the Andromeda board for sensing.Edit: Note that I did not render the threads on the bed screws, nor the screws holding the Andromeda through the spacers to the aluminum tube. Sorry, this was more for my own use than to post for others.

-

@supraguy Thank you. This was exactly what I needed to understand. However, I hope you understand that the lack of thread rendering leaves me wondering exactly what thread spacing was used. (I'm kidding. Please don't waste time answering.)

Based on this, I'm guessing that your bed doesn't move, or at least doesn't move in the Z axis?

-

Heh. Standard 3mm thread.

My bed moves on the Y axis, parallel to the aluminum bar.

If I'd designed the printer for this in the first place, I wouldn't need the aluminum bar, the standoffs for the Andromeda boards would simply mount directly to the acrylic frame instead, but since that frame doesn't extend much past the build platform mounting screws by anything even close to the requisite 20mm, this was done to add in the needed stiffened mounting.

-

how would the second from the right actually trigger when pressure was put on the plate? the sensor would 'unflex'?

-

@mikebridge The sensor responds to changes in pressure rather than total pressure. It makes no difference whether the change in pressure is positive or negative except that the polarity of the signal is inverted so you plug the Andromeda in the other way around.

Idris

-

Or flip the board over. So long as the wingnut isn't shorting out circuitry, that is.

-

@supraguy Oh yeah... that's a much better idea

-

@moriquendi phenomenal. How do they deal with low temperatures? Moved my coreXY into the garage to start getting the baby's future room ready and dc42's IR probe doesn't seem to like the near freezing temperatures with the PEI surface.

-

@mikebridge said in Precision Piezo Andromeda:

...dc42's IR probe doesn't seem to like the near freezing temperatures with the PEI surface

That's probably because you are getting condensation on the surface, coupled with the fact that PEI is transparent to IR. Wiping the surface first to remove condensation may help. However, a piezo offers potentially better probing accuracy then the IR sensor can give using PEI as the target.

-

@mikebridge said in Precision Piezo Andromeda:

@moriquendi phenomenal. How do they deal with low temperatures? Moved my coreXY into the garage to start getting the baby's future room ready and dc42's IR probe doesn't seem to like the near freezing temperatures with the PEI surface.

Sorry I cant resist, If I ever needed a reminder why i have a cat this is it.... good luck with the printer in the cold environment, maybe a heater will help.

-

@calvinx oh, we have cats too (thus why all our 3d printers have enclosures), and I told my wife I have a rule of "we can't have more pets than persons living in the house", but she's pregnant now, so we're up to 3 cats and she keeps mentioning wanting a dog too...

@dc42 it was triggering fine against the PEI indoors (the back of the PEI is painted w/ high-temp black paint), and there's no noticeable condensation on the surface, similar error when the bed is cold or hot. perhaps something shifted when it was moved to the garage, I'll check that today.

-

Piezo sensors have no issues with the kind of temperatures you're likely to encounter in a garage. What you do have to be aware of is that the responsiveness does change with temperature. If you tune the system when everything's cold and then probe when it's been sitting with a hot bed for long enough for for the piezos to warm up you may see different results.

Idris

PS, Dogs are persons, just FYI.

-

My experience is this:

The piezo sensors like consistent temperatures. A change of more than about 10 deg C up or down will change how the system responds. It's getting cold here, and with the drop in temperature, I find that I need to use a space heater to keep the temperature around the printer more consistent in order not to need to make adjustments, which I'd rather avoid. My printer is in the attic, and in the summer, it's mid to upper 20s up there. In the winter, it's in the middle teens, and my last print I had my first false trigger with the Andromeda. I turned on a space heater and re-started everything when it got to 22 degrees up there, and everything was great. I assume that I could have readjusted the trigger threshhold on the board, but I want to avoid making those adjustments if at all possible. Besides, cooler air temperatures are likely to change the printing characteristics of the extruded plastic, too, so keeping a consistent temperature for use is a good thing.

If your printer is enclosed, and you are keeping a consistent temperature for printing anyway, I can say that I have noticed no ill effects from the Andromeda boards being stored in low temperatures, but I think the coldest that I might have tried to use it would be maybe 14°C

-

@dc42 turns out the glass cracked under the PEI sheet and that was causing the inconsistent readings. replaced w/ a geckotek spring steel build plate (see my other thread on the high temp magnetic sheet if people want more info) and my readings are very consistent now.