Trying to understand pattern-sensitive under-extrusion

-

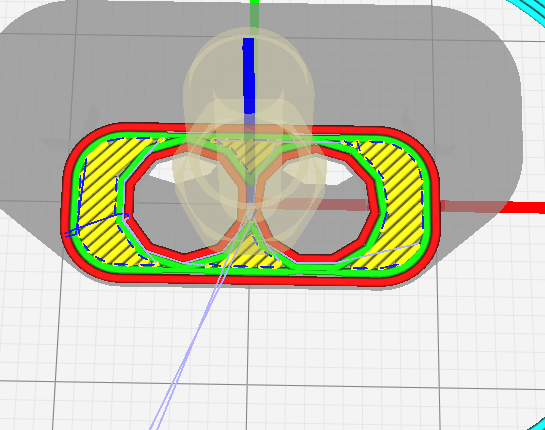

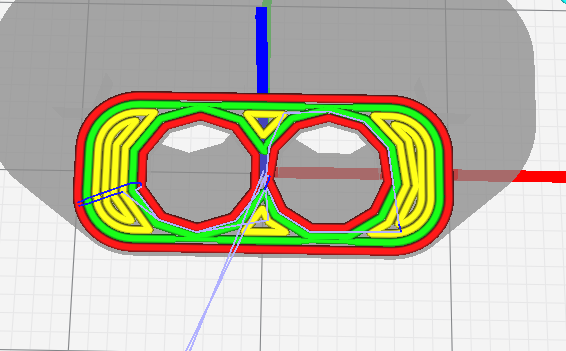

I have a small part that I print often on my Kossel Mini using PLA. I print using moderate speeds and the parts normally come out very nice. I have found that on the first layer, depending on the skin fill pattern used, I can get bad under-extrusion on the latter part of the skin. i.e. the skin starts off not under-extruded but by the time the last of the skin is printed, there's definite under-extrusion visible. That occurs when I use either lines or zig-zag pattern. If I use concentric pattern for the skin lines, no under-extrusion occurs. Here are the first layers for each of those skin patterns (skin is yellow).

The lines pattern suffers from increasing under-extrusion as it is printed from left to right.

The concentric pattern doesn't suffer from any under-extrusion (again it gets printed from left to right).

I have tried lots of combinations of retraction settings including no-retraction and it makes almost no difference.

So I am wondering what's going on here? Could it be that when printing lines (or zig-zag) across a narrow region, the nozzle pressure is gradually diminishing because the nozzle is changing direction abruptly after each short extrusion? Conversely, when printing the concentric pattern, is the nozzle pressure being maintained because the extrusions are longer and with fewer abrupt changes in direction?

Anybody got any thoughts on this?

Thanks.

-

What are your speed and slicer settings?

-

As mentioned above, I have tried lots of different settings which made next to no difference.

Currently, I am using PLA, 0.4mm nozzle, 200deg, no heatbed, line width 0.5mm, speed 20mm/S.

If I print using zig-zag or lines for that layer, it underextrudes. If I print with exactly the same settings except that I use concentric pattern for the skin, it doesn't underextrude.

Duet settings are:

M350 X16 Y16 Z16 E16 I1 ; Set 16x microstepping with interpolation

M92 X80 Y80 Z80 ; Set axis steps/mm

M906 X1000 Y1000 Z1000 E1400 ; Set motor currents (mA)

M201 X3000 Y3000 Z3000 E3000 ; Accelerations (mm/s^2)

M203 X20000 Y20000 Z20000 E1800 ; Maximum speeds (mm/min)

M566 X1200 Y1200 Z1200 E1200 ; Maximum instant speed changes mm/minuteI do not modify accel or jerk in the slicer.

Extruder is now a Bondtech BMG, before I was using a Titan and it exhibited the same behaviour.

As an aside, apart from this underextrusion, which is fixed by using the concentric skin pattern, the print quality got noticeably better when switching from the Titan to the BMG. It wasn't that bad before but it's even better now.

-

What is anything is the difference in the total extrusion commanded by the slicer between the two infill patterns?

-

For the concentric pattern, it uses 0.760531m for the whole print, for the lines pattern it uses 0.760672m.

I'm only changing the skin pattern on the first layer, everything else in the print is the same.

-

Hi @dc42 , I guess I want to increase my understanding of the dynamics of the nozzle pressure when printing a sequence of short lines and what happens when it involves either 90 changes in direction or travel moves.

-

As the filament consumption is the same to within 0.14mm (and greater for the lines pattern), then assuming the extruder isn't skipping steps and nonlinear extrusion isn't significantly in play, the under-extrusion that you are seeing must be being countered by over-extrusion somewhere else.

Are you using pressure advance? Without it, short printing moves will tend to be under-extruded in the middle and over-extruded at the ends. Is that what is happening when you use the lines pattern?

-

@dc42 said in Trying to understand pattern-sensitive under-extrusion:

As the filament consumption is the same to within 0.14mm (and greater for the lines pattern), then assuming the extruder isn't skipping steps and nonlinear extrusion isn't significantly in play, the under-extrusion that you are seeing must be being countered by over-extrusion somewhere else.

Are you using pressure advance? Without it, short printing moves will tend to be under-extruded in the middle and over-extruded at the ends. Is that what is happening when you use the lines pattern?

I am not using pressure advance and, yes, I would say that the lines are under-extruded more in the middle compared to the ends.

I forgot to say above that it is, of course, a bowden extruder.