Laser Filament Monitor - test results

-

@fma yes you are right, and that could account for some of the difference between the different filaments in my original tests.

-

Hello,

So it seems like i have successfully set up the filament monitor and i am getting good data back. My question is, is the goal to print a whole bunch of different things using different filaments, and then report back the percentages? eg, for my first test print with the filament monitor:

I am using matterhackers black ABS filament, 1.75mm

M591 D0

Duet3D laser filament monitor on endstop input 3, disabled, allowed movement 40% to 120%, check every 3.0mm, current position 7.3, brightness 91, shutter 17, measured minimum 97%, average 100%, maximum 105% over 547.9mmIs that the information you want?

Thanks!

-

@qdeathstar yes! Exactly. You are getting good results with ABS, which I did as well. Also worth noting what housing you used and how you mounted it.

-

An idea -

Could we do something where we could use a macro at the start of a print to extrude 10mm (or however much is "enough" to get a good reading) at 1mm/s, measure the amount the laser sees extruded. Then set that as 100% as a correction. Then that value could last through that print, and would theoretically be a way to automatically correct for different filament colors / types.

Obviously this would require a purge area, that not all printers have, but for those the macro could do a single line print at a designated spot, like a purge line.

-

@kraegar That's an interesting thought. We will though need some data first on how consistent the sensor behaves throughout a spool of one filament.

If it is purely dependent on color and type of filament this would be a great solution. If it also varies along the filament... it might still give a better baseline than having to set very relaxed boundaries. So after rethinking I like this idea!

-

@wilriker Agreed on inconsistencies with a spool. I'm also thinking it'll have to be combined with non-linear extrusion calibration.

-

@kraegar But then again the sensor - given it would be sufficiently accurate - could assist in tuning non-linear extrusion beforehand.

Let's wait and see where we get with it.

Probably tomorrow, I will eventually print the housing for my sensor. Loaded black filament tonight and redid bed leveling so I am set.

-

Yep, I'm thinking if we find a "best" filament for monitoring, that would be the ideal one to use for tuning non-linear extrusion.

-

Ok, So here is another test:

Black ABS - Matterhackers - Benchy Test

Calibrated Steps/mm 441M591 D0

Duet3D laser filament monitor on endstop input 3, disabled, allowed movement 40% to 120%, check every 3.0mm, current position -9.6, brightness 94, shutter 17, measured minimum 94%, average 100%, maximum 105% over 3972.5mm

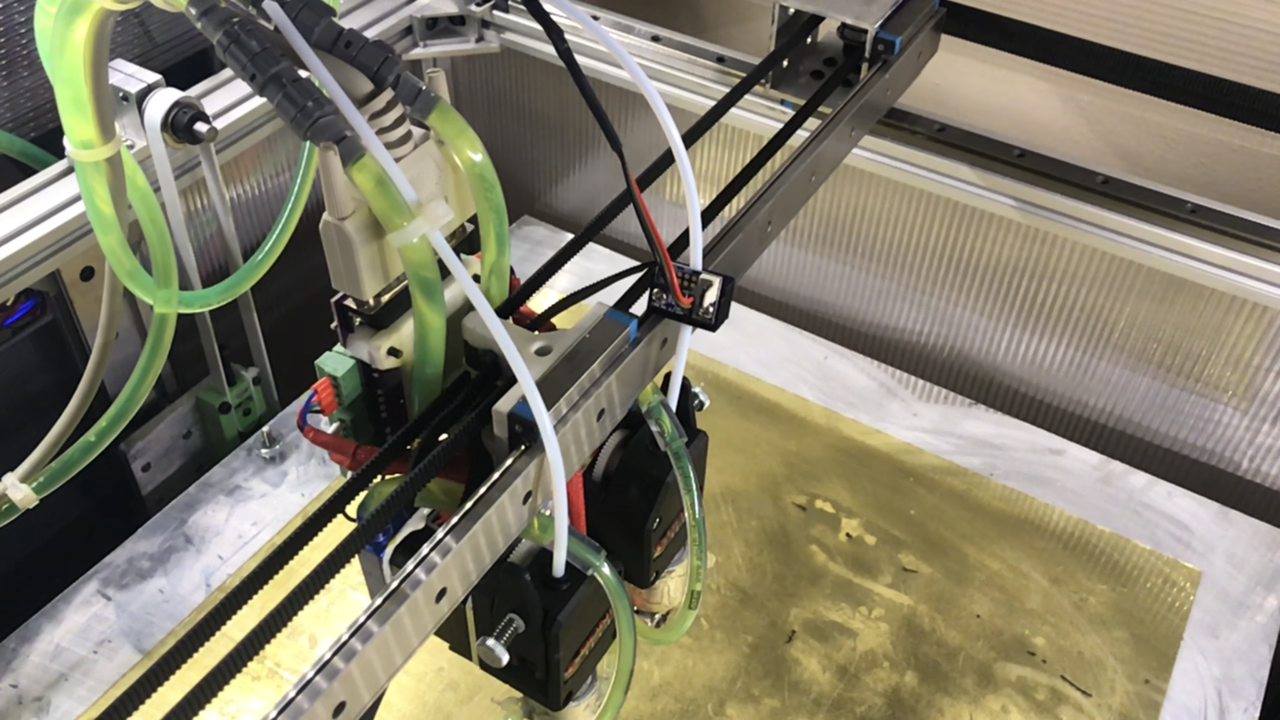

I am using the fully enclosed mount provided in the documentation and it is mounted about 3" above the extruder. I am using a bondtech BMG extruder direct drive.

I am going to run the test again now with white ABS.

-

Just a few layers in, the laser monitor appears to be consistently under reporting the white abs. I am going to let this test go, double check my steps/mm calibration, then retest with my work lights off...

-

Hey everyone, I'm a little late joining the party but I'm here. Let's see if I get this all right.

Current Setup:

1 Filament Sensor on E0

Mount printed in Proto-Pasta Matte Fiber Black (hoping the matte helps with the readings)Photos of custom mount + block provided via Thingiverse (not modified from STL yet)

Ok, I think that's everything about my setup. I did wonder though are we running the sensors disabled 100% of the time or is that up to us whether we want it active or not? Ie, if we get froggy and want to activate it after we feel confident with it do we want that data or just keep collecting data points.

Also, haven't looked into it, but couldn't we get the M591 D0 data dumped to a file automagically at the end of each print? I feel like I saw enough commands in the the RepRap playbook that that feels possible. I might dig into that.

Thanks, I'l be back with data, for now, I'm off to torture my filament sensor with matte fiber, CF, and glitter!

- TinkerZ

-

@tinkerz said in Laser Filament Monitor - test results:

I did wonder though are we running the sensors disabled 100% of the time or is that up to us whether we want it active or not? Ie, if we get froggy and want to activate it after we feel confident with it do we want that data or just keep collecting data points.

That's entirely up to you. Once you know how a particular filament behaves with the sensor, you may feel confident to do prints with the sensor enabled. If you switch to a different filament, I suggest you run with the sensor disabled for a little while to see if it plays nicely with the sensor.

Also, haven't looked into it, but couldn't we get the M591 D0 data dumped to a file automagically at the end of each print? I feel like I saw enough commands in the the RepRap playbook that that feels possible. I might dig into that.

I don't think it's possible right now, but it sounds like a good idea. Something like an M-code that causes non-trivial output from the following code(s) on the same line to be copied to the log file.

-

Hi all,

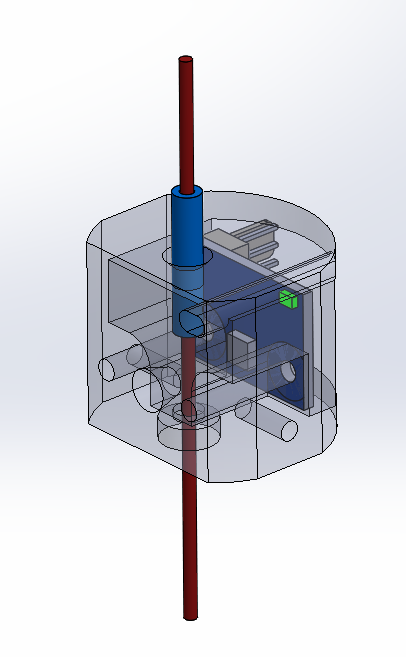

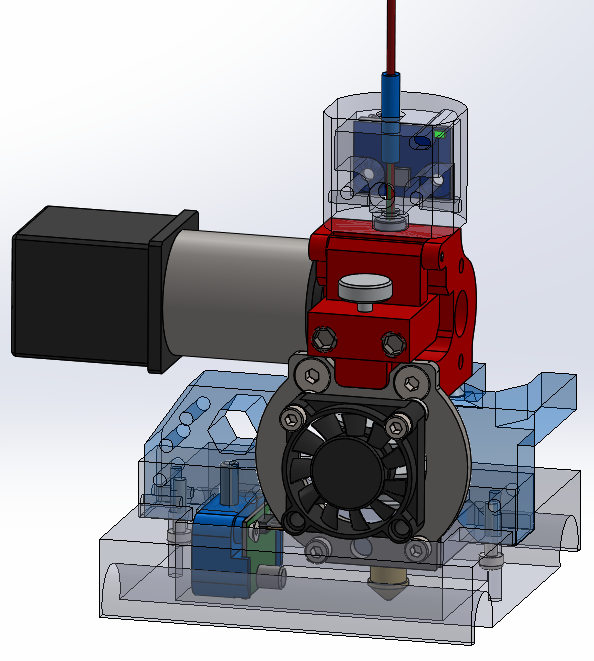

I designed a housing for the sensor, which will enable me to install the sensor on top of the Extruder, to eliminate undetected movment during retractions and improve reading accuracy.

The enclosure will be printed using a black filament to minimize IR reflections.

Currently, the distance between the sensor to the filament is set to 8[mm], because that what David recomneded.Here are some images:

The housing is still under development, so it would be beneficial to read the feedbacks before printing and testing the first version.

As soon as I will print and test it, I will share and upload the CAD files to Thingiverse.

-

@guyaros That looks great. actually during test on the filament we used etc we got the best readings at 9mm gap but that is not conclusive. worth trying a variety of gaps.

-

@guyaros Isn't the filament window in line (at least partially) with the filament sensor and therefore lacking in the background for the sensor to compare against? Ie, isn't light getting to the sensor?

I do love the design and was like "yes, let's print it. can I have the step file so I can put it on my extruder mount?" And was enjoying the filament window when it suddenly hit me that it may be letting light get to the sensor.

Thoughts? Have you tried it yet?

-

@t3p3tony said in Laser Filament Monitor - test results:

we got the best readings at 9mm gap but that is not conclusive.

Strange, I could swear I saw 7mm in the first post but checked and it says 9mm.

I wanted to start with what you tested. So it's good that my print of the housing today failed already at the brim.

worth trying a variety of gaps.

I already sliced all (integer) gaps 4-9mm to accommodate this.

@tinkerz There also is an open variant of @dc42's original housing so a filament window is not necessarily bad but it has to be tested as well.

-

@t3p3tony Did you use the open or closed version of the housing for the above tests? It does not say so in the text.

-

@wilriker Thanks for clearing that up about there being both opened and closed. I saw the closed but also saw the one making reference to divergence of the light with the angled window. Guess I just assumed they had eliminated that already. Carry on all!

-

@wilriker sorry, used the open version. I have also tried closed won other tests without a conclusive improvement, possibly due to internal reflection.

-

Sure, i will re-run the last test. The light blue filament is about 2 years old, so im not sure if that might have something do do with the reading. I think it might have detected some real slippage there.