Laser Filament Monitor - test results

-

@qdeathstar The documentation is updated with more information, including the critical dimensions. https://duet3d.dozuki.com/Wiki/Duet3dFilamentMonitor_LaserVersion

-

I have just updated the documentation to bring it up to date with current firmware. Please use firmware 2.01 or the forthcoming 2.02beta if you are testing the laser sensor.

-

Received the filament sensor earlier this week and printed a case (the default one on Thingiverse) in black PLA.

Initial results with the filaments I had to hand as follows:

Currently running a 28 hour print using the yellow PLA and sensor enabled with the current state:

SENDING:M591 D0

Duet3D laser filament monitor on endstop input 3, enabled, allowed movement 40% to 120%, check every 3.0mm, current position -7.0, brightness 89, shutter 15, measured minimum 78%, average 94%, maximum 114% over 43930.2mmI haven't yet tried alternative case designs - planning to take a look at that later.

I also have a Prusa I3 mk3 for comparison and my initial impressions of the sensor are very positive.

I need to do more testing of filament sensing and failing along with recovery processes. I do like the way the Prusa will pause, prompt you and eject/reload filament with just a few clicks on the control panel. I am not sure yet how we can define macros to perform similar functions since I think we would need access to the filament sensor state but that is for another day ...

Peter

-

@dc42 said in Laser Filament Monitor - test results:

I have just updated the documentation to bring it up to date with current firmware.

I found one thing that is somehow missing:

InHardware -> Assembly -> 2)last sentence starts withAdd the washers [...]

but they have not been mentioned anywhere before especially not in the

Other Partstable. I guess one should use nylon washers here, right? -

@wilriker I think they are optional with the new PCB design as normal nyloc nuts can't cut any PCB traces or short anything. Washer will help protect the PCB and are best practice, and yes they should by nylon.

-

@t3p3tony OK. I should have some nylon washer left from the Duet. They are for M4 instead of M3 - but experience showed they also kind of work good enough for M3 screws (like when the holder you design for M4 screws ends up with too small holes... not that this ever happened to me

).

).P.S.: I received my sensor yesterday (the day you said they should arrive "around now" - do you have a spy at my post office?) and designed my holder for the sensor housing today as well as extended the sensor housing to be screwed to my holder. I will have to fix something on my Y axis first but I guess I can print these parts probably on the weekend.

-

@T3P3Tony, did you re-calibrate the extruder steps/mm for each filament?

-

@fma no I did not - I was "extruding" into free air rather than through a nozzle so there was no really back pressure on the filament so the variation should have been less than in a real printer however if your extruder has variations in steps/mm depending on filament then worth doing that.

-

Well, I think that there are always variations, even when extruding in free air: ABS is softer than PLA, so gear teeth go deeper, resulting in a smaller apparent diameter... And it would be worse when really extruding.

This means that different filaments should be calibrated changing the steps/mm, and not only with a extruding ratio on the slicer side.

-

@fma yes you are right, and that could account for some of the difference between the different filaments in my original tests.

-

Hello,

So it seems like i have successfully set up the filament monitor and i am getting good data back. My question is, is the goal to print a whole bunch of different things using different filaments, and then report back the percentages? eg, for my first test print with the filament monitor:

I am using matterhackers black ABS filament, 1.75mm

M591 D0

Duet3D laser filament monitor on endstop input 3, disabled, allowed movement 40% to 120%, check every 3.0mm, current position 7.3, brightness 91, shutter 17, measured minimum 97%, average 100%, maximum 105% over 547.9mmIs that the information you want?

Thanks!

-

@qdeathstar yes! Exactly. You are getting good results with ABS, which I did as well. Also worth noting what housing you used and how you mounted it.

-

An idea -

Could we do something where we could use a macro at the start of a print to extrude 10mm (or however much is "enough" to get a good reading) at 1mm/s, measure the amount the laser sees extruded. Then set that as 100% as a correction. Then that value could last through that print, and would theoretically be a way to automatically correct for different filament colors / types.

Obviously this would require a purge area, that not all printers have, but for those the macro could do a single line print at a designated spot, like a purge line.

-

@kraegar That's an interesting thought. We will though need some data first on how consistent the sensor behaves throughout a spool of one filament.

If it is purely dependent on color and type of filament this would be a great solution. If it also varies along the filament... it might still give a better baseline than having to set very relaxed boundaries. So after rethinking I like this idea!

-

@wilriker Agreed on inconsistencies with a spool. I'm also thinking it'll have to be combined with non-linear extrusion calibration.

-

@kraegar But then again the sensor - given it would be sufficiently accurate - could assist in tuning non-linear extrusion beforehand.

Let's wait and see where we get with it.

Probably tomorrow, I will eventually print the housing for my sensor. Loaded black filament tonight and redid bed leveling so I am set.

-

Yep, I'm thinking if we find a "best" filament for monitoring, that would be the ideal one to use for tuning non-linear extrusion.

-

Ok, So here is another test:

Black ABS - Matterhackers - Benchy Test

Calibrated Steps/mm 441M591 D0

Duet3D laser filament monitor on endstop input 3, disabled, allowed movement 40% to 120%, check every 3.0mm, current position -9.6, brightness 94, shutter 17, measured minimum 94%, average 100%, maximum 105% over 3972.5mm

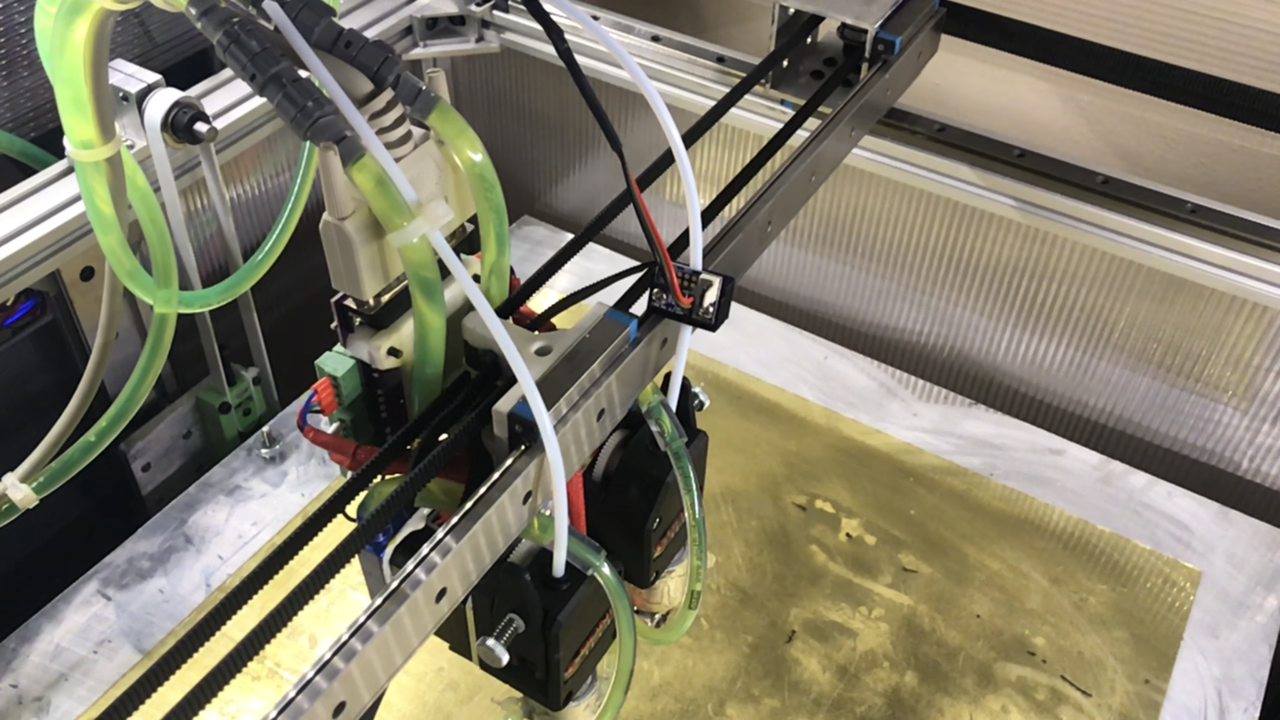

I am using the fully enclosed mount provided in the documentation and it is mounted about 3" above the extruder. I am using a bondtech BMG extruder direct drive.

I am going to run the test again now with white ABS.

-

Just a few layers in, the laser monitor appears to be consistently under reporting the white abs. I am going to let this test go, double check my steps/mm calibration, then retest with my work lights off...

-

Hey everyone, I'm a little late joining the party but I'm here. Let's see if I get this all right.

Current Setup:

1 Filament Sensor on E0

Mount printed in Proto-Pasta Matte Fiber Black (hoping the matte helps with the readings)Photos of custom mount + block provided via Thingiverse (not modified from STL yet)

Ok, I think that's everything about my setup. I did wonder though are we running the sensors disabled 100% of the time or is that up to us whether we want it active or not? Ie, if we get froggy and want to activate it after we feel confident with it do we want that data or just keep collecting data points.

Also, haven't looked into it, but couldn't we get the M591 D0 data dumped to a file automagically at the end of each print? I feel like I saw enough commands in the the RepRap playbook that that feels possible. I might dig into that.

Thanks, I'l be back with data, for now, I'm off to torture my filament sensor with matte fiber, CF, and glitter!

- TinkerZ