Need ideas for inline wire connectors for steppers

-

Hi.

Several of the motors I am using on a build have the wiring harness connected internally within the motor, rather than a connector. This has some obvious drawbacks. For one you have fixed length to work with. And you get whatever wire they give you, rather than proper motion, or cable carrier rated wire.

Since this is a large corexy I don't think the wire leads will be long enough to reach the duet board which will be installed in a proper control box on the side of the machine.

What I would like to do is cut the factory leads off short leaving a pigtail. Install a connector. Then run my own shielded cable to the controller. (shield to be terminated at one end, probably to the frame near the motor).

I would prefer something more secure than Dupont connectors, and I am sort of lost when it comes to the numerous options options for various molex connectors.

I have also seen this done using a fancy Wago connector on an industrial CNC machine that I installed.

Anyway. I am curious if anyone has any input on some good solutions for this.

Thanks.

-

When I find stepper motor cables too short, I just solder extra lengths of colour-coded twisted wires to them and insulate the joints with heatshrink sleeving.

-

If the wires come right out of the motor, I wouldn't cut them short. I prefer to wrap the extra length up with a zip tie and/or use it as strain relief.

WAGO's are good replacements for bus type connectors up to 5 wires, but not so great for multi lead cables because you need one WAGO for each wire in the cable.

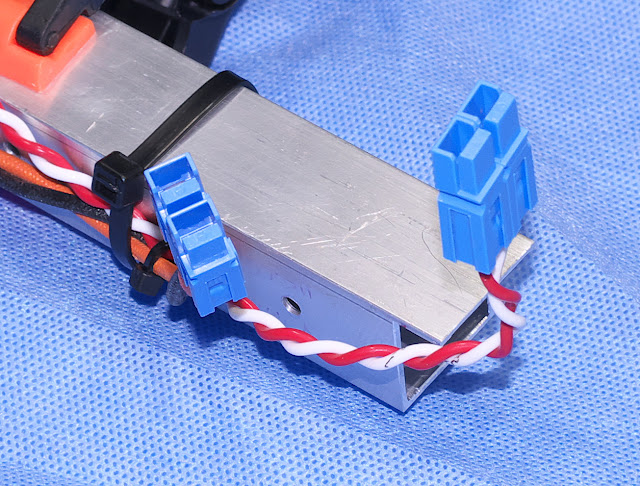

Anderson power-pole connectors are good because you can create multi-wire connectors just by stacking them, and they can be stacked so they can only be put together one way, eliminating the possibility of wiring errors. They come in different sizes with different current capacities, though the smallest ones are still sort of bulky. These are power-pole connectors- one is for low voltage control input to an SSR and the other for AC Line voltage:

-

I've extended the motor leads on my printer using dupont connectors and secured them with a wrap of electrical tape. The wires don't move though. If you want a true locking connector look for Molex KK series such as those that come with the Duet, or for something even more heavy duty JST SM series. Those are often seen on hotend and thermistor connections.

JST kit on amazon I have used: https://www.amazon.ca/gp/product/B0188DMF3A/ref=s9_dcacsd_dcoop_bw_cr_x__a_w

Molex KK:

-

@phaedrux said in Need ideas for inline wire connectors for steppers:

JST kit on amazon I have used: https://www.amazon.ca/gp/product/B0188DMF3A/ref=s9_dcacsd_dcoop_bw_cr_x__a_w

Molex KK:

Thanks for posting that JST kit. I had not been able to find a kit yet with both male, and female plug housings. (The one I have has PCB mount headers) . I will pick one of those up to use for fans etc... at the very least.

-

@mrehorstdmd said in Need ideas for inline wire connectors for steppers:

If the wires come right out of the motor, I wouldn't cut them short. I prefer to wrap the extra length up with a zip tie and/or use it as strain relief.

I see the point of strain relief but that might make you end up with a high quality cable connected to an arbitrary quality and possible tiny gauge cable still connected to the motor.

-

I had originally started down the road of connectorizing, tried several different styles, then gave up. Motors don't go bad so often that connectorizing is worth the effort. I left the motor tails long and just went with butt splices. Lightly twist the black/green wires together and the red/blue wires together to help reduce EMI.

In an effort to eliminate my EMI induced false endstop triggers, I've also dumped my 18ga parallel conductors in favor of 22ga shielded twisted pair for both the motors and endstops. Black/green motor wires on one pair and red/blue on another.

Oh yeah...also a lot less bulky at the Duet2 since I've got 8 motors.