-

This is very cool, thanks for the thorough report. I am looking forward to seeing some pictures.

I note your point about homing the Y. It looks like you have solved the issue I was having at MRRF with the P3 on the dual axis uncombined and recombining by explicitly putting P4 on the uncombined and P3 on the recombined axis. I should have tried that but it was busy so quite rushed. I will pass this on to 3ddistributed!

-

I already did quite a lot of machining after connecting the Duet board and more serious things came up.

(1) I tried pausing a file and I saw the machine moving to absolute 0, passing just 0.5mm above a workpiece fixture while having a rather expensive end mill in the spindle. Lesson properly learned… the content of the pause.g file must be removed! While leaving the Z movement to 5mm above the workpiece might sound interesting, if the Z axis is too close to the top there might be undesired side effects.

(2) Related to the above, leave only "G1 R1" in the resume.g file, but insure that the tool is relatively close to the workpiece and the direct path to the position where the files was paused is not going to interfere with anything.

-

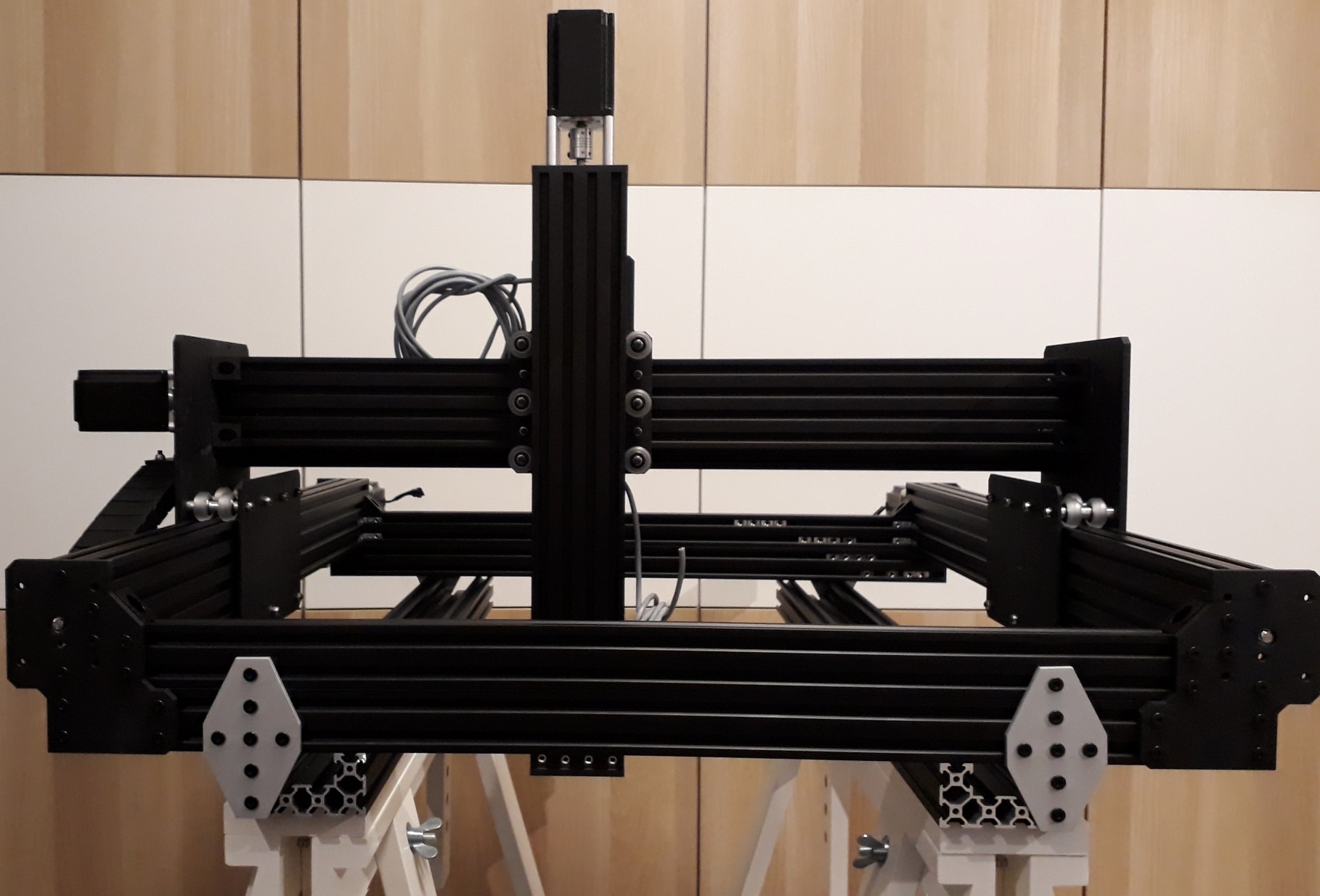

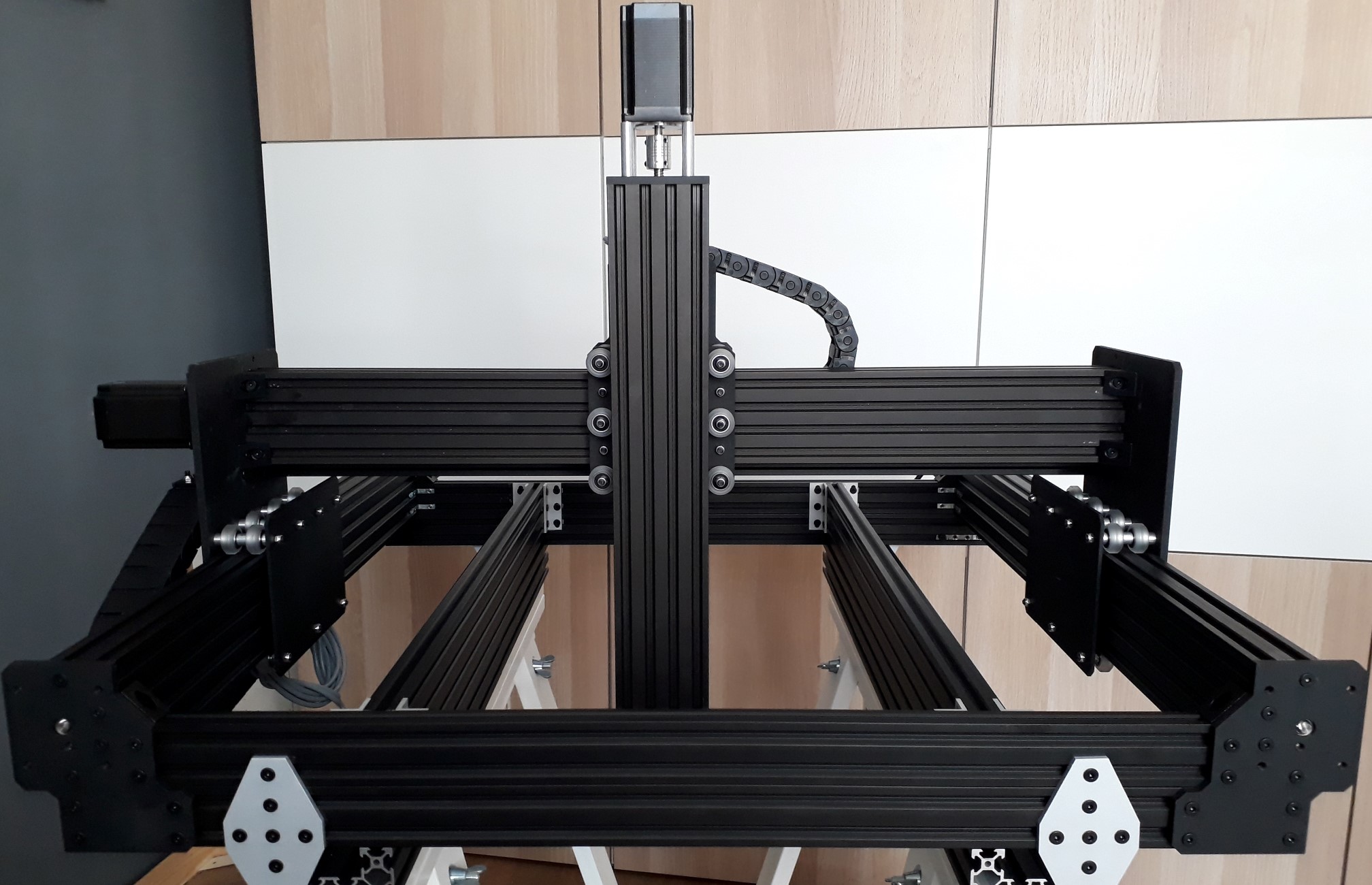

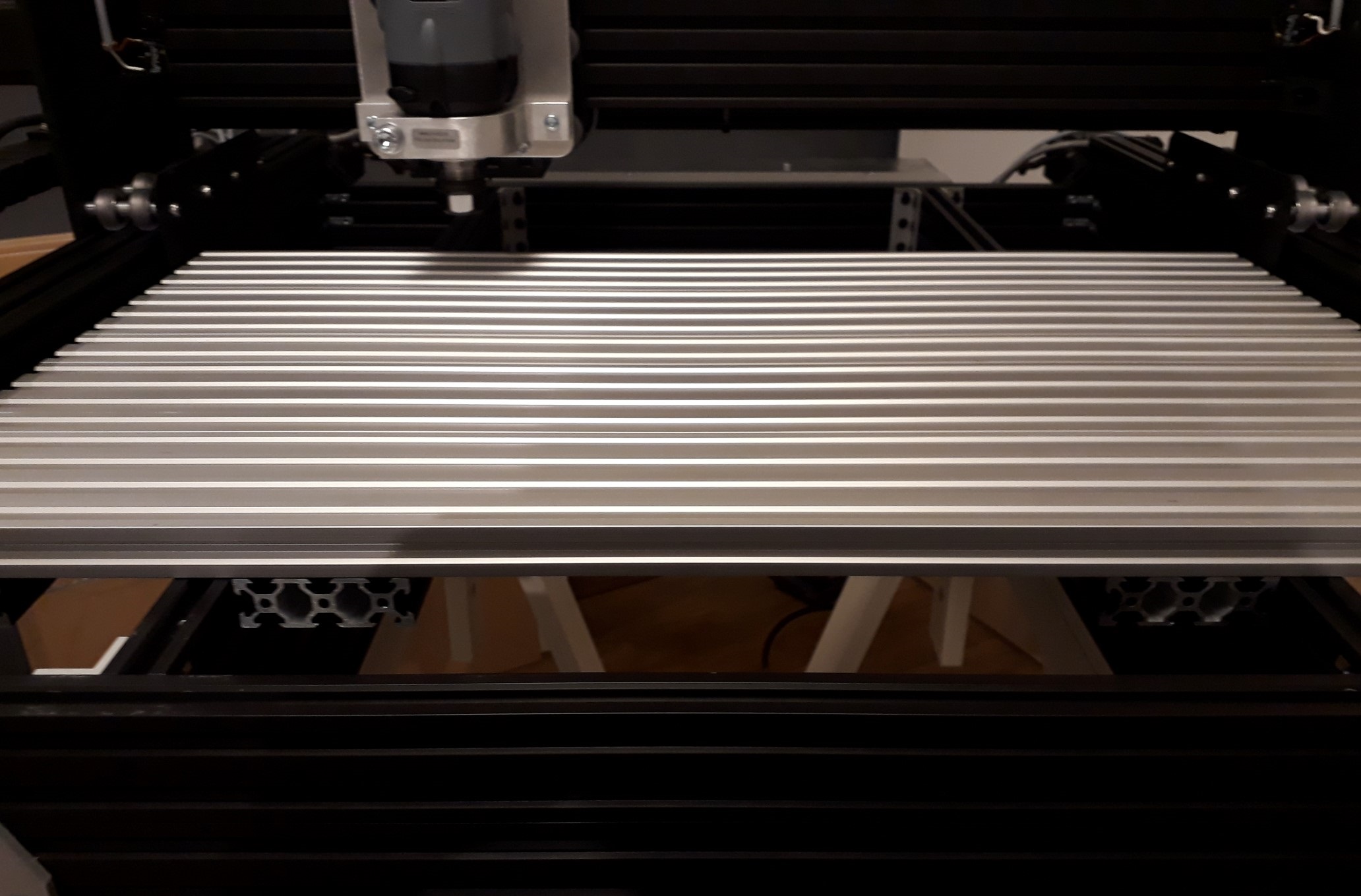

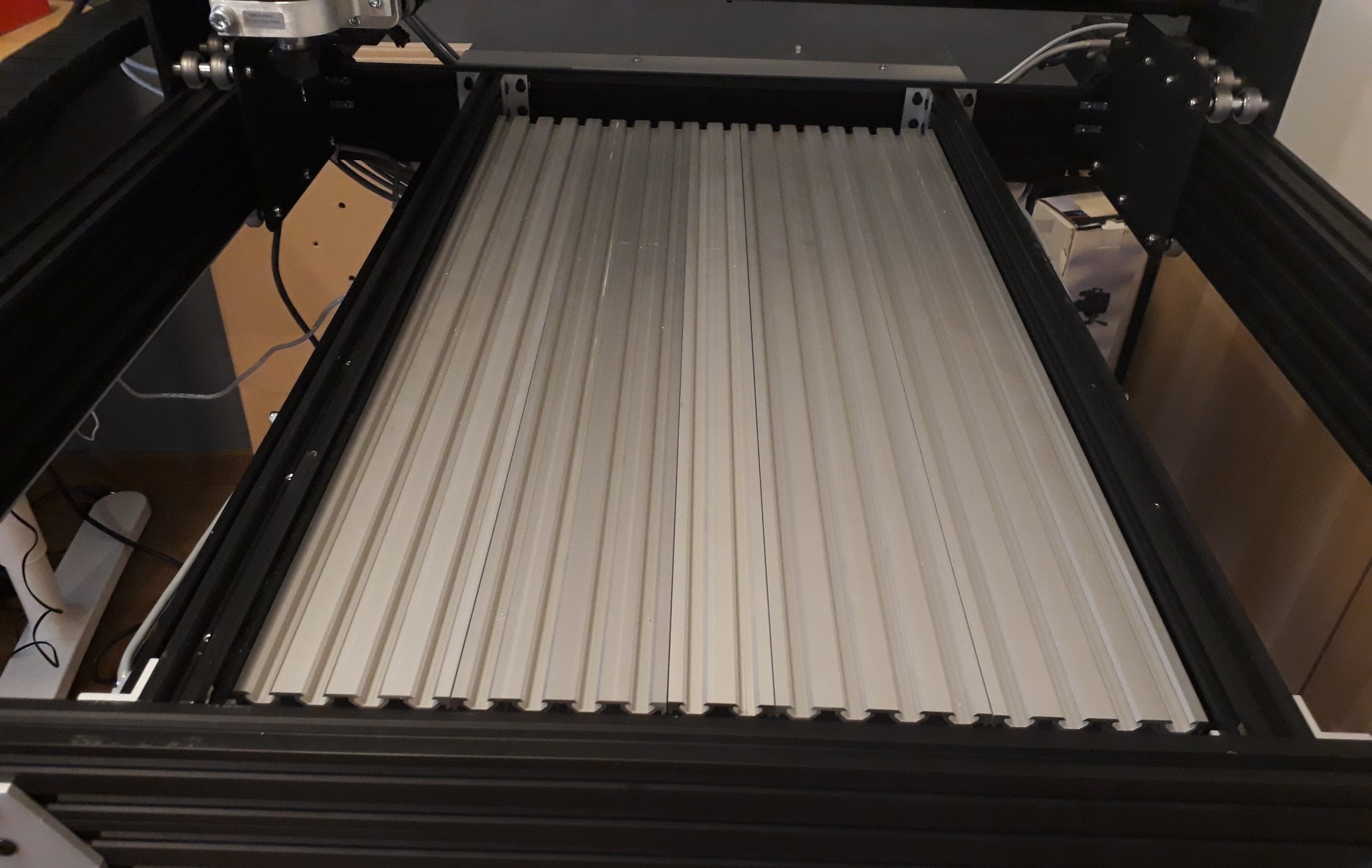

Now some pictures of the machine.

This is the whole frame, with extended Z that can visibly reach well below when machining in some tall item. The C-Beam extrusions below the front and rear beams are non-standard and are intended for extra rigidity and mechanical support for the whole machine when used as open frame.

Here the machine is fully built, including drag chains.

A table built from V-slot extrusions, installed in the highest position possible, for machining items from thin raw materials.

The same table installed in the central area for thicker items.

Duet3D support, including a, 80mm 24V fan. That took me about 30-40 minutes to design and mill from standard Aluminum profiles and 5 minutes to put together.

Installed Duet3D and PSU on the rear beam, under a large Aluminum sheet to prevent damage from milling residues.

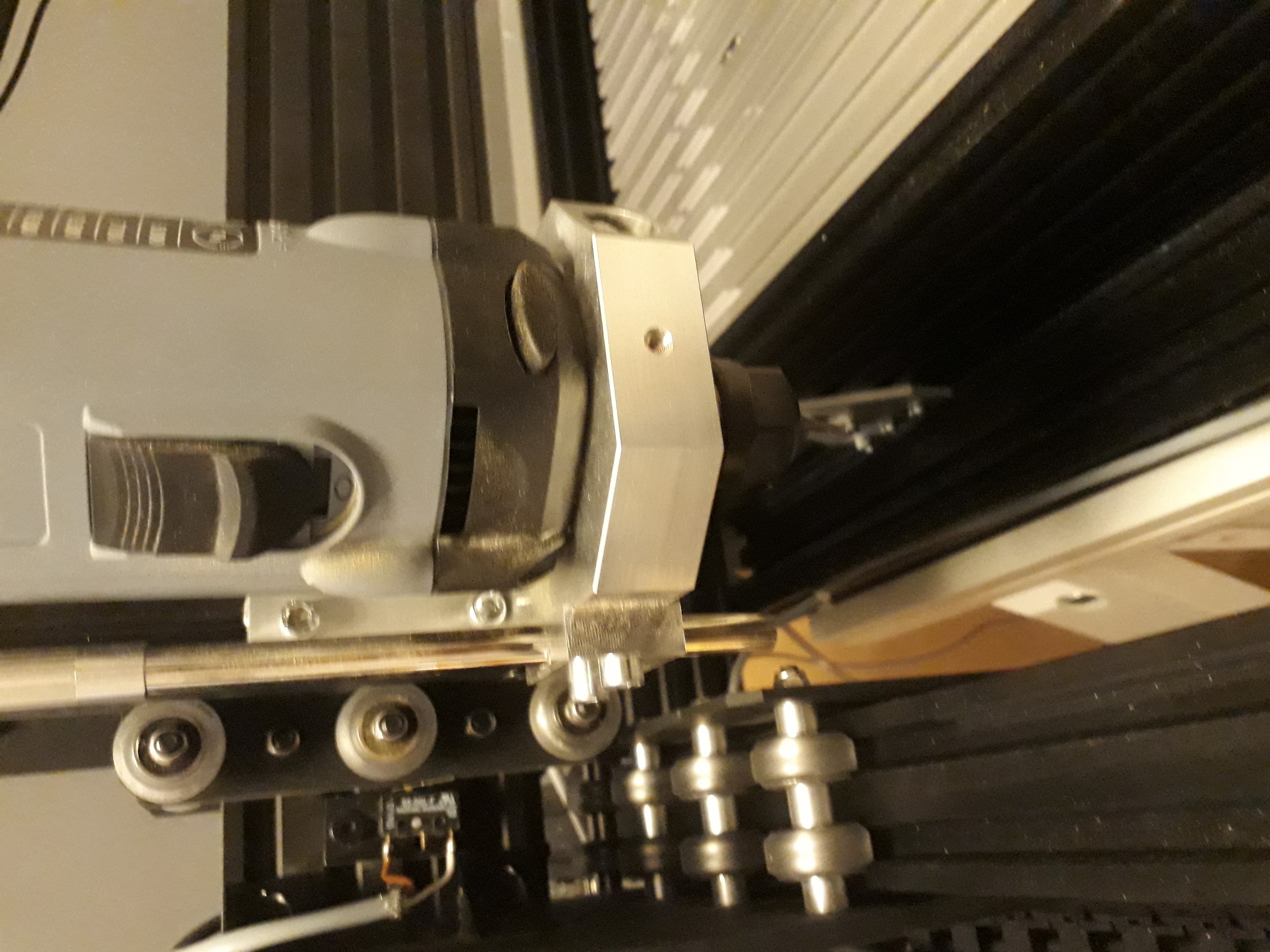

Kress spindle and USB microscope for X/Y aligning of the raw material.

-

I have created a basic page on using RepRapFirmware to control CNC machines at https://duet3d.dozuki.com/Wiki/Configuring_RepRapFirmware_for_a_CNC_machine. Those of you using Duets to control CNC machines, please feel free to edit it.

-

Cool beans, thanks for the info, I've been planning to make a cnc router with a spare mks board, but I guess a third Duet isn't far away…

-

Thank you for posting this. im just getting setup and this is very helpful

-

After a lot of tests done with G2/G3, based on issues discovered while trying to machine a rather small Aluminum item, the maximum jerk should be limited to 300mm/min for X, Y and U. So change in config.g the line for M566 to:

M566 X300 Y300 Z12 U300

-

Thanks for the feedback!

-

OK, this is a bit amusing since I just purchased a workbee, have a duet wifi spare and a bunch of time. While waiting on it to show up here i'm spending some time creating a post processor for Bobcad/cam that'll work with the duet. Shouldn't be too terrible to make it work right.

-

@abbott_m I made one for CamBam. Actually two of them as firmware versions prior to 2.0 were not 100% compatible with GCode standards (proper or de facto ones). So if you go for firmware 2.0 you just need to avoid some GCodes that are not supported for now - like G17, G18, G19 (I have actually removed only G17 as it is safe considering that the Duet3D works only on the XY plane for now, but I left the others in place so I get an error if I configure anything wrong during CAM).

Which WorkBee have you chosen? Belt or lead screw?

-

By using latest firmware at the time of writing this, that is 2.01beta2, the maximum jerk can be safely increased to 400mm/min. Also the G2/G3 behavior, visible especially during some trochoidal machining paths as generated by CamBam, is fixed. Based on more tests that have to be done, the maximum jerk could be further increased.

-

@catalin_ro

That's interesting. Any updates?

-What kind of stepper motors are you using, Nema 23?

-Hows the duet stepper motor drivers handling the nema motors torque? -

@cncpro

Not much! The WorkBee is now changed to an 800W air cooled spindle bought on AliExpress and I have also added a 4th Axis that I install only when needed.The steppers are NEMA 23 rated for 3A, 345oz*in. They are way stronger than what the WorkBee would need.

The 3A steppers are handled very well by the Duet drivers when using a 24V PSU, much better than the GRBL+DRV8825 combo I have initially used (left over from previous CNC, until the Duet had enough CNC capabilities!). Using some higher voltage capable drivers might help getting higher RPMs but the lead screws are normally limited around 300RPM to avoid melting the Delrin nuts. With the OpenBuilds "standard" lead screws that gives 2500mm/s. For my needs that is quite enough, though I consider some times beefing up the mechanics a little bit (at 8mm thickness the lead screws a little wobbly) - but I need to find enough spare time for finding a solution.

-

@dc42 can you post current post processors on this page?

-

@adamfilip I don't know if David has any CNC mill post processor for the Duet. All I can help you with is the CamBam 1.0 one. I have used it extensively and it is working very well with firmware 2.0 and newer. As I can't upload the file (it's name is Duet3D v2.0.cbpp), here is its content:

<?xml version="1.0" encoding="utf-8"?>

<PostProcessor xmlns:xsi="http://www.w3.org/2001/XMLSchema-instance" xmlns:xsd="http://www.w3.org/2001/XMLSchema" Version="0.9.8.0">

<ToolChange />

<CutterCompOff />

<WorkplaneXY />

<VelocityModeExactStop />

<VelocityModeConstantVelocity />

<EndRewind />

<Repeat />

<SpindleCW>M3 {$s} G4 S30</SpindleCW>

<SpindleOff>G4 P0 M5</SpindleOff>

<RotaryAxis>B</RotaryAxis>

</PostProcessor> -

I asked Ryan from Ooznest about the post processor they use for Duet and they said they just use standard GRBL

-

It may be of interest that RRF 2.02RC7 supports Fanuc-style GCode in the sense that where you have a sequence multiple G0, G1, G2 or G3 commands, after the first line the subsequent lines can just specify the new coordinates (and feed rate if necessary), omitting the G command.

-

@adamfilip GRBL might work as post processor with the latest firmware, I admit! 8 months ago that was not possible and I have added the dedicated CamBam post processor because of that.

-

With the latest rc7 firmware, fanuc postprocessor should work, I'll make a powermill post and post it here once it's done. It should be pretty easy now. It'll work with featurecam and artcam too.

If you looked for it, any cam should include a fanuc post. -

@dc42 I am currently running the latest firmware on duet wifi but I am getting a bad command error on the line with no G command when running a GCode file. I don't know if I am missing something.

For example:

G1 X100 Y100 F2000

X200 Y200

G1 X0 Y0The gantry moves to X100 and Y100 then back to 0 only