Smart Effector 8-pin cable connector failure

-

@oryhara the only issue have seen with the 8-pin JST connector on Smart Effector 4 on my delta is that the plug doesn't lock in to the socket positively enough, so that under some conditions the cable can partially pull the plug out of the socket. I temporarily solved the issue by providing a little more slack on the cable. I've not had any problem with the crimps.

However, what I should really do is print a tripod-like part to attach to the three mounting holes on the Smart Effector so as to provide a point to which the cable can be tied, thereby preventing the cable pulling on the plug. This would also prevent the cable being flexed from side to side on the plug, which could result in the wire fracturing internally where it enters the crimp. If you use your printer a lot, that may be what is happening on your machine. So I recommend adding such a strain relief.

-

@dc42 a CAN-FD enabled smart effector would be nice...

-

@jay_s_uk yes I've been pushing for one for a long time. Unfortunately the projected sales volume is low.

-

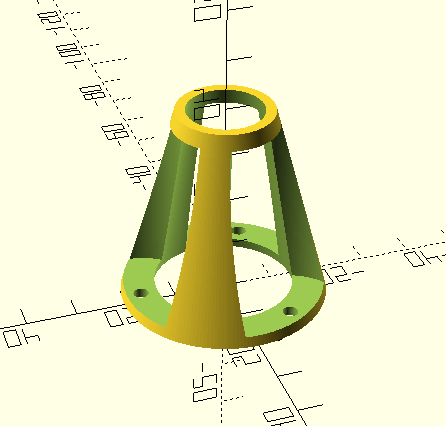

@oryhara here's an idea of what I had in mind to provide points to anchor the cables to. I can provide the OpenScad file if it's useful to you.

-

@dc42 said in Smart Effector 8-pin cable connector failure:

@jay_s_uk yes I've been pushing for one for a long time. Unfortunately the projected sales volume is low.

Does this mean it's unlikely to happen? I'd really like one that was CAN, and preferably also slightly larger to simplify mounting an extruder. I thought I'd seen reference to this being something that might happen, but if that's now not the case I'll start thinking about getting a toolboard and an extruder onto my current smart effector.

-

@achrn yes I'd like a CAN-connected tool board/Smart Effector for my delta too; and like you I would want it larger, to support modern lightweight direct drive extruders.

-

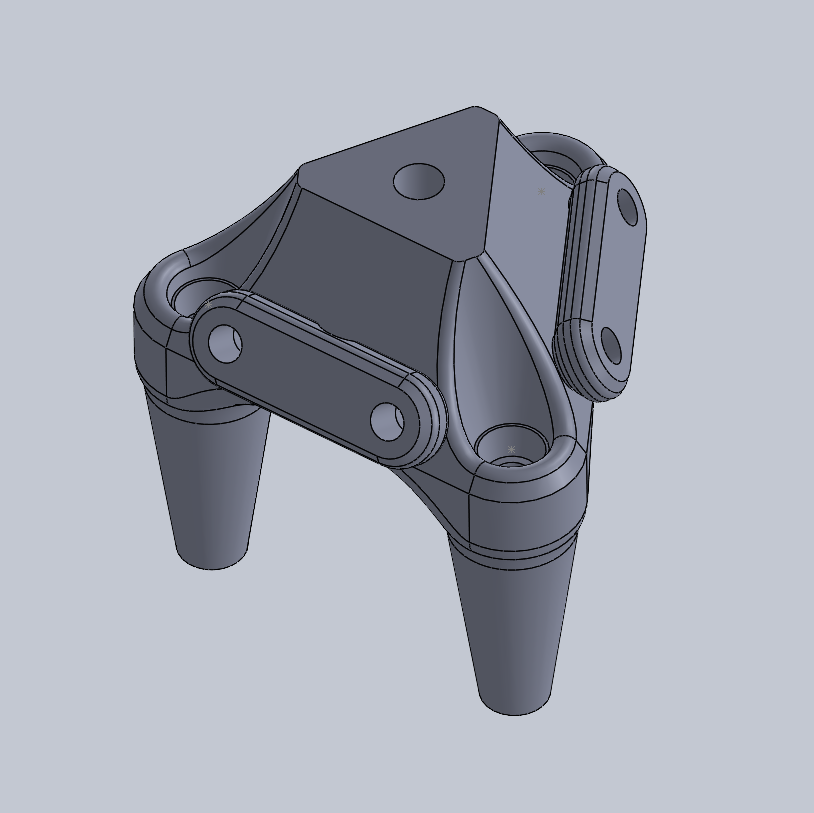

I had a similar idea. its much bulkier than it needs to be for sure. I'm not obsessed with speed. I'd rather have rock-solid reliability.

In use, I found the cables wiggled enough for the conductor within to break at the point where they are 'clamped' to the strain relief part(the 2 flat bars pictured clamp wires to the strain relief piece). I think I was also clamping it too tightly.

-

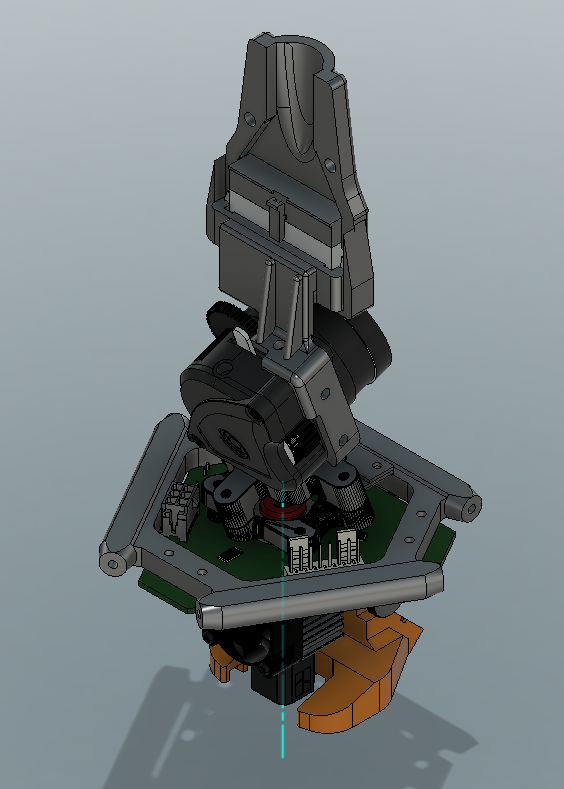

@oryhara I am currently working on this:

I am using 2x12p microfit connectors to take all the strain

-

@ignacmc I've had the wires to the Microfit 3 connector for heater and fan power break just above the pin when I didn't use strain relief. Whereas it's easy to remove pins from KK and JST connectors and fir new ones, it's hard to remove pins from Microfit 3 connectors. That's why we only use them when we need the current-carry capacity they provide.

-

@dc42 there are printable microfit pin removal tools for people that can't or won't spring the 40+EUR for a genuine pin removal tool.

-

@dc42 Yes. My idea is having a solid strain relief anchor point on top of the direct extruder. As I am routing 23 wires to the hotend (heaters, fans, extruder, smarteffector and accelerometer) I am using a 2x12p Microfit and from there routing the wires in bundles to the molex KK and JST. I expect those connectors downstream of the Microfit will not suffer any stress because all is taken by the Microfit. I agree that the Microfit is not an easy connector to deal with. I bought a cheap extractor from aliexpress that seems to do the work