AFTER UPDATE TO 3.5 Beta 4

-

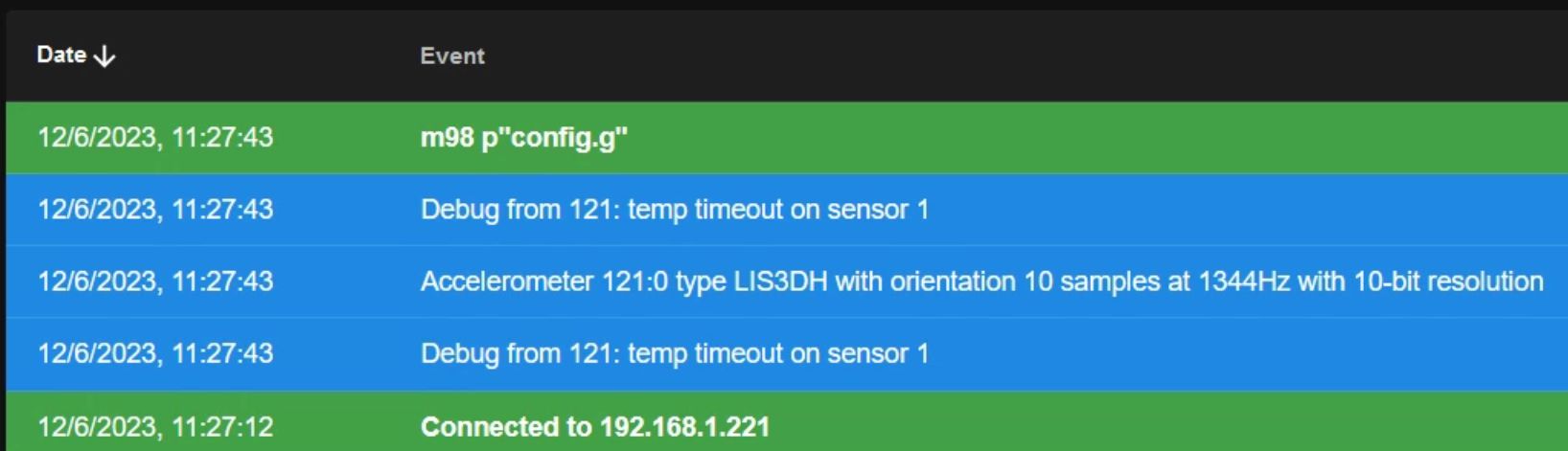

I get an error on sensor 1, after the firmware update to Beta4 (see print screen).

I don't know if it's a real error or just a warning...This is my system: ( Voron 2.4)

RepRapFirmware for Duet 3 MB6HC version 3.5.0-beta.4 (2023-06-08 23:41:30) running on Duet 3 MB6HC v1.01 (SBC mode) Board ID: 08DJM-956BA-NA3TN-6JTDJ-3SJ6S-1T82VDuet TOOL1LC rev 1.1 or later firmware version 3.5.0-beta.4 (2023-06-08 16:22:30)

Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10)My config.g:

; Note: Core XY Voron 2.4 Duet3 ( SBC RASPBERRY SD 64GB ) ; ; ---------- GENERAL PREFERENCES --------- G4 S2 ; WAIT 1 SEC FOR 1LC G90 ; absolute coordinates... M83 ; relative extruder moves M669 K1 ; Select CoreXY mode M564 S1 H1 ; Forbid axis movements when not homed M575 P1 S1 B57600 ; enable support for Paneldue display ; ; ---------- DRIVES MAPPINGS ---------- ; ; Rear ; | Z1 | Z2 | Z2 - Z1 ; -----+----- ; | Z0 | Z3 | Z3 - Z0 ; -----+----- ; Front ; M584 X4 Y5 Z0:1:2:3 E121.0 ; set drive mapping +++ possible swap X and Y M569 P0 S1 ; Z0 motor FL goes forwards M569 P1 S0 ; Z1 motor RL goes backwards M569 P2 S1 ; Z2 motor RR goes forwards M569 P3 S0 ; Z3 motor FR goes backwards M569 P4 S1 ; A motor goes forwards M569 P5 S1 ; B motor goes forwards M569 P121.0 S0 ; E1 motor Extruder goes backwards (scheda 1LC porta 121) M671 X-67.5:-67.85:422.5:422.5 Y-10:443.8:443.8:-10 S10 ; Define Z belts locations (Z0=Front_Left Z1, Z2, Z3...ecc) S10=mm di correzione massima ; ; ---------- DRIVES PARAMETERS ---------- M350 X32 Y32 Z32 E16 I1 ; configure microstepping with interpolation M92 X158.5 Y158.5 Z800 E1678 ; set steps per mm M98 P"/macros/print_scripts/setup_printing.g" ; MACRO con parametri di Jerk, speed, accel, corrente. ; ; ---------- AXIS LIMITS ---------- M208 X0 Y0 Z0 S1 ; set axis minima (S1) M208 X340 Y350 Z350 S0 ; set axis maxima (S0) ; ; ---------- ENDSTOP --------- M574 Y2 S1 P"!io1.in" ; Configure enstop Y(2) posizione alta dello switch e pin !io1.in invertito M574 X2 S1 P"!io2.in" ; Configure enstop x(2) posizione alta dello switch e pin !io2.in invertito ; M591 P2 C"121.io1.in" S1 D0 ; filament monitor connected to E0_stop su scheda espansione 1LC porta 121 ; ; ---------- Z-PROBE ---------- M558 P8 C"!121.io1.in" H20 F500 T5000 ; set Z probe type inductive (P8), altezza tastatura (H5), velocità tastatura mm/min (F500), velocità di spostamento mm/min (T6000) su scheda espansione 1LC porta 121 G31 P500 X0 Y24 Z3.32 ; set Z probe trigger value, PIU' ALTO E' Z PIU' SI AVVICINA AL LETTO M557 X5:335 Y5:345 S63 ; define mesh grid (GRIGLIA maglia 5 x 5 con 63mm di spazio) ; ; ----------- HO - HEATERS BED ---------- M308 S0 P"temp0" Y"thermistor" T100000 B4138 A"LETTO" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 R0.961 K0.467:0.000 D3.05 E1.35 S1.00 B0 ; 28/05/22 DOPO AUTOTARATURA LETTO CON (M303 H0 P1 S90) M140 H0 ; map heated bed to heater 0 ; ; ----------- H1 - HEATERS NOZZLE ---------- ; M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 A"ESTRUSORE" ; Configure sensor 1 as thermistor on pin temp1 M950 H1 C"121.out0" T1 ; Create nozzle heater output on out0 su scheda espansione 1LC porta 121 and map it to sensor 1 M307 H1 R4.216 K0.327:0.000 D8.25 E1.35 S1.00 B0 V29.4 ; DOPO AUTOTARATURA NOZZLE CON (M303 H1 P1 S250) il 05/06/23. M143 H1 S275 ; set temperature limit for heater 1 to 275C ; ; ---------- TOOLS ---------- M563 P0 S"TOOLS-0" D0.5 H1 F0 ; DEFINE TOOL 0 => P0=Tool 0, S"..."=Tool name, D0.5=drive 0.5, H1=heather 1, F0=fan 0. G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; ; ---------- FAN 0 VENTOLA RAFFR. STAMPA PWM (out4) 24v ---------- M950 F0 C"121.out2" Q500 ; Fan 0 su 121.out2, use PWM, using 121.out2 M106 P0 C"VENTOLA FILO" S0.0 H-1 ; set FAN_0 name and value. ; ; ---------- FAN 1 VENTOLA HOTEND (out8) 24v ---------- M950 F1 C"121.out1" Q500 ; Fan 0 su 121.out2, use PWM, using 121.out2 M106 P1 C"HOTEND" H1 L0.1 X0.5 B0.3 T60:250 ; PARAMETRICA Termostatica ( da 30% a 100% con temp. da 70°C a 250°C ) ; ; ---------- FAN 2 VENTOLA MCU PWM (out5) 24v --------- M308 S3 Y"mcu-temp" A"MCU" ; configure sensor 3 as thermistor for MCU M950 F2 C"!out5+out5.tach" ; Fan 2 su out5, use PWM (needs ! inverted), using out5.tach M106 P2 C"VENTOLA MCU" L0.1 X0.8 B0.1 T26:35 H3 ; set FAN_2 value T26:32°C velocità ventola L-10% X-80% ; ; ---------- FAN 3 VENTOLA PWM RASPBERRY (out6) 24v --------- M308 S4 P"temp2" Y"thermistor" T100000 B4138 A"RASPBERRY" ; Configura il sensore 4 (S4) come riscaldatore sul pin temp2 con nome RASPBERRY M950 F3 C"!out6+out6.tach" ; Fan 3 su out6, use PWM (needs ! inverted), using out6.tach M106 P3 C"VENTOLA RASPBERRY" L0.1 X1.0 B0.9 T35:45 H4 ; set FAN_3 value T35:45°C velocità ventola L-10% X-100% ; ; ---------- PORT 1 RELE' ACCENSIONE (io4.out) IO PORT PWM ---------- M950 P1 C"io4.out" Q500 ; allocate GPIO PORT.1 to io4.out at 500Hz ; M42 P1 S0.0 ; Printer OFF set 0% PWM on GPIO port 1 ; M42 P1 S1.0 ; Printer ON set 100% PWM on GPIO port 1 ; ; ---------- ACCELEROMETRO ---------- M955 P121.0 I10 ; ACCELEROMETRO SU SCHEDA 1LC (I10 = orientamento scheda) ; ; ---------- PULSANTE FISICO CHE ATTIVA MACRO ---------- ; M950 J5 C"io5.in" ; ; Crea trigger n°5 su porta "121.button0" M950 J5 C"121.button0" ; Crea pin 5 su porta 121.button0 della scheda 1LC M581 P5 T2 S1 R0 ; P5=pin 5 creato con M950 (J5), T2=Trigger logico a cui associare gli ingressi, S1=funziona da inattivo ad attivo, R0=attivo in ogni momento ; Qualsiasi numero di trigger # maggiore di 1 provoca l'esecuzione del file della macro sys/trigger2.g (T2) M950 J6 C"121.button1" ; Crea trigger n°6 su porta "121.button0" M581 P6 T3 S1 R0 ; Crea pin 56 su porta 121.button1 della scheda 1LC ; ;---------- EMERGENCY BUTTON ---------- ; M950 J7 C"121.button0" ; Crea trigger n°7 su porta "121.button0" ; M581 P7 T4 S1 R0 ; configurara pin IN N°7 (P7), ed aziona trigger 4 ; ; ---------- NEOLED ---------- ; M150 X1 Q3000000 ; SPI frequency to 3MHz M950 E0 C"led" T1 M98 P"0:/macros/7C-NEOLED ITALIA.g" ; Esegui la MACRO "7C-NEOLED ITALIA.g" ; M150 R255 U255 B255 P90 S25 F0 ; Luce bianca per 25 led potenza 90 su 255 ; M150 R0 U0 B255 P200 S24 F0 ; Set luce BLU per 24 LED ; ; ---------- MISCELLANEUS ---------- M912 P0 S-1 ; parametro per tarare la temperatura della MCU (-1°C) ; M911 S24.5 R24.9 P"M913 X0 Y0 G91 M83 G1 Z3 E-2 F500" ; Autosalvataggio stampa per mancanza di corrente, sospende a 25.0v e riparte a 25.8v M300 S2500 P3000 ; Emette suono a S=2500Hz per P=3 secondi T0 ; select first tool ACTIVE ; ---------- END SCRIPT ----------- ; ; ; ---------- FUNZIONI NON PIU' ATTIVE ---------- ; ; ---------- FAN 4 LUCE LED su RISCALDATORE (out3) 24v ---------- ;M950 F4 C"out3" Q1000 ;create FAN_4 on pin out3 and set its frequency at 1000hz ;M106 P4 C"LUCE LED" S0.1 ;LED ON AL 10% ;M106 P4 S0.0 ;PER SPEGNERE LED ; ; ---------- SERVOCOMANDO RC ---------- ; M950 S2 C"out9" ; assign GPIO port 2 to out9 (Servo header) ; M280 P2 S100 ; S25 fine corsa DX S175 fine corsa SX S100 centro corsa ;Do I need to change any parameters? Before with Beta3 I didn't get any warnings...

-

@Gianluca just to make sure: Did you also update the firmware on the toolboard?

-

@Gianluca you can ignore that warning if sensor 1 is giving sensible readings. I have seen that warning too. In previous firmware versions there wasn't anywhere for that message to be displayed, so I don't think it is new.

I have created a Github issue for this, https://github.com/Duet3D/RepRapFirmware/issues/866.

-

@oliof Yes, by SBC...

-

@dc42 Thank you for your great work!!!