David's IR Sensor: Questions

-

I'm building a 500mm CoreXY and unable to use bltouch, due to the magnetic field of my custom bed.

I want to run David's IR sensor, as the form factor is perfect for my printhead design. I am normally used to printing on PEI flex sheets, but I understand that will not work with this sensor. I do not have the means to bake a black grill paint coating underneath a PEI sheet.

I am considering going with the Buildtak black nylon surface. Will this work ok?

Also, are there any other recommendations any other flex sheet build surfaces that will work well with this sensor, with similar characteristics to PEI? I print ASA about 90% of the time.

Thanks

-

@br7408

I use two sensors (BLTouch & dc42's IR Probe).

I only use the BLTouch on print surfaces where the IR probe has its problems.

99% of the time the IR probe is in use.I have a matte black GRP (glass fiber reinforced plastic) FR4 from Printbay.

It is the Blackprint, as already mentioned, it is matt black and has no imprints such as a company logo or any stripes or patterns.I've been using this Blackprint for a few years and it's still just as great as it was on day one.

I mainly print nylon and ABS.

The Blackprint has no trouble with ASA.The plate consists of a magnet system (magnetic plate for the aluminum bed and the flexible black print itself is also magnetic.

It should work with your existing magnetic board.Printbay also manufactures to measure and has sizes over 500x500mm.

Printbay video of me.

Here I show how the "matched pair technique" of the blackprint works.

The magnetization of the plate is "strip-like" and thus the plate is always exactly aligned horizontally.

But normal spring steel PEI plates also work for me, but then this strip-shaped magnetization is not available and the PEI plate can be moved "continuously" even though it is held magnetically.I can only recommend this Blackprint. In addition, of all the records I know, she looks the hottest.

I hope I could show you something new.

Please write here which record you last chose.

Purely out of curiosity and interest

Google Translate

----- Original Text -----Ich nutze zwei Sensoren (BLTouch & dc42's IR Probe).

Den BLTouch nutze ich nur bei Druckoberflächen wo der IR-Probe seine Probleme mit hat.

Zu 99% ist der IR-Probe im Einsatz.Ich habe eine mattschwarze GFK (Glasfaserkunststoff) FR4 von Printbay.

Es ist die Blackprint, sie ist wie bereits erwähnt, mattschwarz und hat keinerlei Aufdrucke wie zB ein Firmenlogo oder irgendwelche Streifen und Muster.Ich nutze diese Blackprint schon einige jahre und sie ist noch genau so toll wie am ersten Tag.

Ich drucke hauptsächlich Nylon und ABS.

Mit ASA hat die Blackprint keine Schwierigkeiten.Die Platte besteht aus ein Magnetsystem (Magnetplatte für das Alubett und die biegsame Blackprint ist selber auch magnetisch.

Sie sollte mit Deiner bestehenden Magnetplatte funktionieren.Printbay fertigt auch auf Maß und hat Größen über 500x500mm.

Printbay Video von mir.

Hier zeige ich zeige wie die "Matched Pair Technik" der Blackprint funktioniert.

Die magnetisierung der Platte ist "streifenförmig" und somit ist die Platte horizontal immer exakt ausgerichtet.

Bei mir funktionieren aber auch normale Federstahlblech PEI Platten, dann ist diese streifenförmige magnetisierung aber nicht vorhanden und die PEI Platte kann "stufenlos" verschoben werden obwohl sie magnetisch gehalten wird.Ich kann diese Blackprint nur empfehlen. Zudem sieht sie von allen Platten die ich kenne... am geilsten aus.

Ich hoffe ich konnte Dir etwas neues zeigen.

Bitte schreibe hier, für welche Platte Du Dich zuletzt entschieden hast.

Rein aus Neugier und Interesse

-

@br7408 it may work against a PEI coated flex sheet, if the surface colour is uniform (or you can avoid probing at points where it isn't) and the PEI layer is thin. Worth a try. The IR sensor doesn't work well against a sheet of PEI on top of a bed plate, because the reflections from the front and back surfaces interfere and the thickness is large enough for that to matter.

Let me know how well it works. If we can find a surface that works well enough, then with a firmware change we could run it as a scanning Z probe.

-

PS there is another coating you can get on flexible build plates called PEX. I don't know whether this is also transparent to IR. If it isn't then it could be a good solution.

-

@Norder Thank you very much for that information. I will look into that plate and report back what I end up going with.

-

@dc42 I saw the PEX ones as well, some say they work better than the PEI.

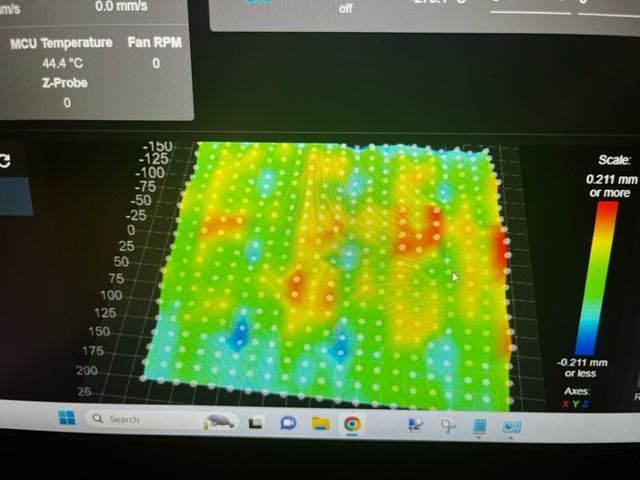

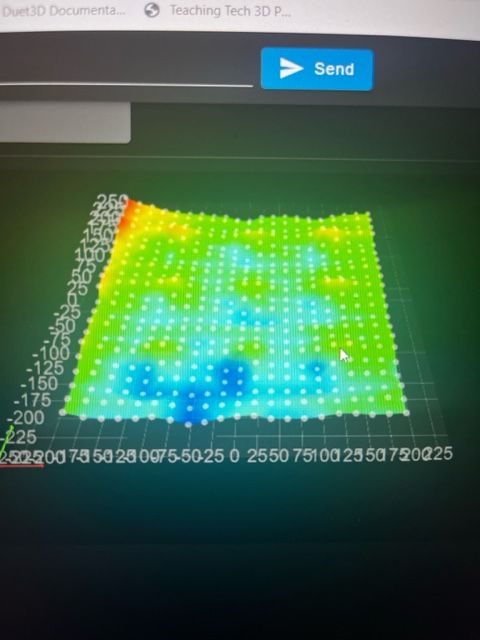

I have the sensors on order, and I will design & draw up a new CAD mount once I get them. I currently have a PEI sheet that came with the printer, so I will do an initial test with that. Anything is better than this bltouch as it is giving crazy readings due to this bed.

-

@br7408

Regarding the falsified measurement results of the BLTouch due to the disturbing magnetic fields... I once posted something about this with a solution that works quite well, depending on which metal you use.

Maybe it will help you ?Link to Thread:

https://forum.duet3d.com/topic/29491/hint-bltouch-incorrect-measurement-due-to-magnetic-print-bed?_=1682329087880Google Translate

--- Original Text ---Zu den verfälschten Messergebnissen des BLTouch wegen der störenden Magnetfeldern... dazu habe ich mal etwas gepostet mit einer Lösung die je nachdem welches Metall man nimmt, ganz gut funktioniert.

Vielleicht hilft es Dir weiter ?Link zum Thread:

https://forum.duet3d.com/topic/29491/hint-bltouch-incorrect-measurement-due-to-magnetic-print-bed?_=1682329087880 -

@br7408 For what it's worth, it is my understanding that the Creality CR Touch uses an optical sensor, which shouldn't be affected by magnetic beds. From https://www.creality3dofficial.com/products/creality-cr-touch :

Inside of CR Touch is a small PCB with an electro-magnetically controlled metal probe. The sensing function is via a light-triggered "Hall Effect" switch with a Normally Open design.

Electrically, it's a straight swap for a BLTouch, though it's a different size physically.

Ian

-

@dc42 I have a PEX sheet that I can test (even though it is partially destroyed, it should be sufficient for testing). I am also awaiting some other materials for testing soon, I will let you know how those go.

-

@Norder I tried that with what magnetic shielding tape available at a local store. Minimal improvement as these magnets are very strong.

-

@oliof said in David's IR Sensor: Questions:

@dc42 I have a PEX sheet that I can test (even though it is partially destroyed, it should be sufficient for testing). I am also awaiting some other materials for testing soon, I will let you know how those go.

That would be great. I ordered and received the buildtak nylon surface. I will try that and the textured PEI that I currently have and report back. I should receive the sensors tomorrow and I will start revising my printhead CAD design for mounting provisions.

-

I'm happy to report that Dave's IR sensor works great with TinyMachine's PEI plate and WhamBam's PEX plate. It is ok on textured PEI, but I believe the uneven-ness of the texture throws off the height map slightly.

-

@br7408 thanks for the feedback. I will build new IR sensor firmware soon to test with the scanning sensor support in RRF 3.4beta4.

-

@dc42 3.5b4, no? Also, how would one update the firmware in existing sensors at home?

-

@oliof said in David's IR Sensor: Questions:

Also, how would one update the firmware in existing sensors at home?

You would need a programming tool for AVR microcontrollers, such as a USBASP or AVRISP or an Arduino running the ISP program, plus a 6-pin pogo pin adapter such as https://www.sparkfun.com/products/11591.