Should've stuck with the knockoff GT2560?

-

I really thought if I spent $180 on a board that it'd pretty much work out of the box and come with some clear instructions. I'm pretty handy with tools (I'm an industrial maintenance tech) but I've been working on this thing for two solid days and I'm still not printing. One of my Z steppers wouldn't do anything but stutter so I poked around with my multimeter for about an hour but didn't really change/repair anything and now both Z steppers are working fine but the Y stepper is going in the wrong direction. It was working fine before. Seems like random problems. Damn thing doesn't want to stay connected over wifi, either.

The cheap GT2560 I had wouldn't let me update the firmware and I got tired of having to change the stepspermm for the z-axis (upgraded to leadscrews from threaded rod). I ordered a $40 RAMPS that was basically DOA so I thought I'd go ahead and spend the money and get what everyone said was the best controller on the market because I was starting to get tired of working on my printer more than I was printing. Dropped $180USD and I've been working on it all weekend. A lot of that was spent re-crimping those damn PITA connectors, though.

I don't mean to rant. I'm just really disappointed. The cheap board had some annoying problems but at least I could print. A lot of time and money spent to make my printer worse off that it was before.

-

You'll get there; if you polled all the duet users at 2 days and 2 weeks in you'd get some seriously different satisfaction ratings.

They are a bit alien coming from an 8bit/marlin background, but once you get them running and you see a noticeable improvement in your print quality you'll see what they're all about. It's a steep learning curve.

I also suspect if you look at how many bought a second one as they liked the first one so much it would be quite a high number.

-

That actually makes me feel a lot better. Guess I just needed a little encouragement. Thanks, man.

-

First start looking at which firmware you are running (you can find the info by selecting the settings page, general tab),

you should be running at least 1.19 (https://github.com/dc42/RepRapFirmware/tree/dev/Release/Duet-WiFi/Stable) -

That actually makes me feel a lot better. Guess I just needed a little encouragement. Thanks, man.

You're welcome, you'll find this is one of the most helpful, knowledgeable and polite forums in 3d printing.

Send us some more details of what you're struggling with and we'll soon get you printing awesome stuff.

-

The connectors will take 0.1" / 2.54mm "dupont" connectors, you mainly miss out on the latching mechanism. I didn't spot any kits where you got wires with Molex KK connectors on them. I can crimp these connectors but I just haven't yet, my old connectors will just connect.

I'm impressed with how powerful the platform is but the g code configuration is wearing thin.

-

So the current issue is the Y-axis is going the wrong way? That's an easy fix, change the relevant M569 command in config.g.

I'm a huge fan of g-code based config actually, it means that 1.) configuration of the printer can be changed mid-print and 2.) configuration can be simply and easily overridden using the g-code console which helps for initial testing and setup.

-

Stick with it, the Duet is IMO the best board for 3d printing. The community is very active and helpful, the web browser interface is great. David puts a lot of work into making the firmware better and better, which I don't think you get elsewhere. The initial setup and configuration can be a bit confusing at first but it really is great once you get onto it.

-

So the current issue is the Y-axis is going the wrong way? That's an easy fix, change the relevant M569 command in config.g.

I'm a huge fan of g-code based config actually, it means that 1.) configuration of the printer can be changed mid-print and 2.) configuration can be simply and easily overridden using the g-code console which helps for initial testing and setup.

I'll look into the M569 command. I'm a flunkie maintenance man so I just swapped the motor leads around.

-

Turning the motor plug around is my preferred solution since I'd rather everything turn the "right way" mechanically than in software. And I prefer DuPont plugs to molex so its not a problem t do so (and I'm careful which way around I insert them by default).

All I'd say is that if you were familiar with downloading Marlin, and going through configuration.h and setting all the parameters for your printer manually, then tweaking it by adjusting them and uploading, Duet/RRF is the same but its much easier as you just change the config.g file and hit reboot, or test your change by just sending the gcode at any time, even whilst printing.

If you just downloaded pre-configured firmware for your machine and flashed it and booted it up, then RRF will seem like a lot more ball-ache, but it actually makes you delve much deeper into how the machine works, broadens your understanding of it, and makes changing/upgraded/fault finding in the future far less daunting.

-

I can only speak from my own learning experience. Duet has a steep and sometimes costly (regarding time) learning curve, especially if what you're doing is currently in development

But I will say that David and the forum here are a very dedicated and helpful group of people! Stick with it and once you get your rig up and running, you'll definitely be better for it.

But I will say that David and the forum here are a very dedicated and helpful group of people! Stick with it and once you get your rig up and running, you'll definitely be better for it. -

I can only speak from my own learning experience. Duet has a steep and sometimes costly (regarding time) learning curve, especially if what you're doing is currently in development

But I will say that David and the forum here are a very dedicated and helpful group of people! Stick with it and once you get your rig up and running, you'll definitely be better for it.

But I will say that David and the forum here are a very dedicated and helpful group of people! Stick with it and once you get your rig up and running, you'll definitely be better for it.Words from my mouth. I love this thing once i understood it. Lot's of little quality of life things that impress me daily.

-

I began installing the Duet Wifi on my printer on Friday. I've worked on it all weekend and all day today and still haven't managed a single successful print. Current problem is nozzle height. I've adjust my z-stop and leveled (trammed) my bed over and over again today. It seems like the z axis homes to a different place when I click "Home Z" than it does when it homes to start printing. When I click "Home Z" it'll barely touch the limit switch lever and stop. When it's printing, it smashes the lever all the way down against the body of the limit switch. Just now figured that out. But it's been one thing after another.

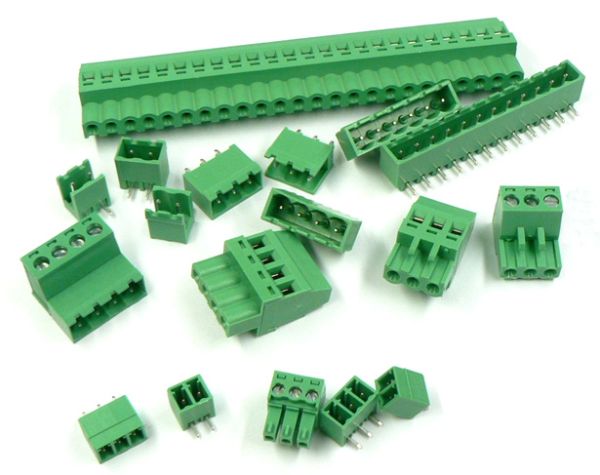

EDIT: Also, what is the deal with using the molex connectors? Luckily I had a pair of the special crimpers because I like buying tools but man, what a pain in the ass. I don't see any advantage molex connectors have over the green terminal block/header plugs like these:

Crimping molex, dupont and jst connectors is pretty fiddly. Seems like there should be a bench-mounted press for those instead of hand-held crimpers. After crimping new molex connectors for everything on my printer, I don't see why those connectors exist at all.

-

What type of printer is it?

-

What type of printer is it?

It's a cheap ebay i3 clone. A Geeetech i3 pro B knockoff made by CTC. Though there is very little left of the original machine.

-

Some of the early Duet 06 boards were manufactured with screw terminals throughout. They were not popular. With screw terminals, you can't disconnect and reconnect motor cables, endstop cables etc. quickly. There is also a much greater chance that users will mis-wire the board, especially after disconnecting and reconnecting several cables.

-

Some of the early Duet 06 boards were manufactured with screw terminals throughout. They were not popular. With screw terminals, you can't disconnect and reconnect motor cables, endstop cables etc. quickly. There is also a much greater chance that users will mis-wire the board, especially after disconnecting and reconnecting several cables.

….....and the risk of stray strands causing shorts - unless ferrules are used throughout (which need to be crimped).

-

The green connectors have screw terminals in a housing and then plug into a header. Alot of the more technical equipment where I work uses them. Maybe I just need practice with the molex/dupont crimper but twisting a wire nice and neat to get it in a terminal sure seems a lot easier than trying to hold those tiny pins by the end to get them to sit in the crimper just right, then close it enough to hold the pin while you try to stick the wire through and try to get it lined up with the wings correctly. But maybe I just suck at it.

My clumsy mechanic hands just better suited to turning a screw driver.

My clumsy mechanic hands just better suited to turning a screw driver.EDIT: Oh, I hope I'm not coming off as too combative or disgruntled. I really am enjoying the board and all the neat things it makes possible. Also, you guys are great and super helpful. I'm extremely grateful. Sometimes I play "devil's advocate" without realizing it just to get/keep a discussion going. I often learn a lot from discussions and learning is always a good thing.

-

I typically buy the arduino DuPont connector kits and just cut the leads in half and solder the wires together then wrap with heatshrink rather than trying to crimp the pins. I guess there is a chance the solder will break down at some point but I havent had trouble thus far. I usually give the wires a good twist together before soldering. I'm all thumbs so crimping pins turns into @!#×$!! If you know what i mean…lol

-

Hang on in there - you'll get there. If a 64 year old carpenter (me) can get get there, so will you. The best advice I can give is just to read through the documentation https://www.duet3d.com/wiki and if you can find the time have scan through this https://duet3d.com/wiki/G-code or at least book mark it for easy reference.

Oh and as you've discovered, we're a pretty well behaved bunch on this forum on the whole - but yes, sometimes playing "Devil's advocate" as you put it, isn't the best way to elicit help.

About the firmware. The Duet team actively seek user input and suggestions for features or improvement. These tend to get acted on promptly which results in frequent firmware updates and new features being added on a fairly regular basis. Whilst this is good for seasoned users, it can make it seem to be a bit daunting for new users who have to try and pick it all up from scratch. Just remember that because a feature exists, it doesn't mean you have to use it. Stick to the basics to start with then play around with some of the more advanced features once you get the machine up and running.

BTW, using a pair of needle nosed pliers to make the initial crimp then finishing off with the proper tool works well for me. I can never get the cable, connector and crimping tool all in the right place to start with.

HTH