Retrofit Hardware

-

-

@Lexan you said they were "normal" Z motors, so I assumed they were bipolar stepper motors without drivers. Is that correct? If so then they need much more than 15mA.

-

@dc42 no i ment 2 steppers, controlled each by one 1lc toolboard, and the servo that lift the current extruder is something similar like this https://www.sunfounder.com/products/25kg-high-torque-servo

-

ah okay i get the issue, so this is an extra servo just for the hotend unit.

my plan for the z axis stepper drivers is to use the TMC5160 from the 6HC board -

@Lexan correct. You can't drive an external driver using a 6HC

-

@Lexan ah i see my fault, the 6XD can, right ?

Edit: just seen that make's no sense for my situation. -

@Lexan yes, the 6XD can.

In the duet 3 family it's pretty much yet the 6XD or 1XD boards for each motor with an external driver -

@jay_s_uk okay this fix the problem that i didnt seen comming, but wont answer my problem i see comming

can i control the 25 kg servo via the 1lc toolboard ?

and if yes, wich port can i use? -

@Lexan do you have a part number for it?

-

@jay_s_uk said in Retrofit Hardware:

@Lexan do you have a part number for it?

i will check that out tmrw, just play with the idea to use a 3hc board instead the 2x 1lc

-

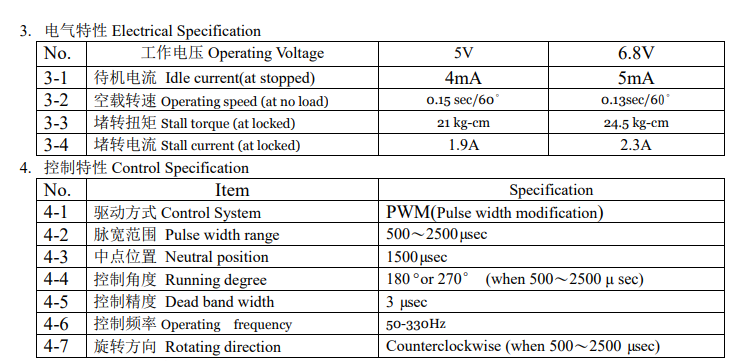

@Lexan should be a DSSERVO DS3225

-

@Lexan said in Retrofit Hardware:

DSSERVO DS3225

I would say not. seems like it can pull up to 1.9A which is too much for a toolboard

-

@Lexan any recommends how to controll this one instead ?

i think ~2A will be also too much for the 6hc -

@Lexan it may well be. Best to just use a step down converter.

The control can still be from the toolboard or 6HC. -

@Lexan okay but then the control could also be from a toolboard, right ?

the way to the hotend is about 4 meters, so i would like to take the cables as short as possible -

@Lexan yes to controlling from the toolboard. you'd either have to run a separate 5v cable or mount a stepdown converter on the toolhead