heatsink for watercooled hotend, dimensions?

-

@cosmowave printing at PLA with a 0.4mm nozzle I have seen success with just a rubber tube around a thin wall tube as a heatsink. so its likely that a much smaller water contact surface will provide sufficient cooling, in comparison with an air-cooled hotend.

-

@cosmowave You don't need fins for liquid cooling. Most of the designs you'll find on the internet are for adapting air cooled heat sinks which already have fins. But if you are starting from scratch, you don't need them. My 6 input hot end is liquid cooled so I have 6 heat breaks which happen to be PTFE lined but that's optional. So the heat breaks are simple tubes, 6m diameter which slide into a cooling block which has 6 off 6.05mm diameter holes. The coolant path is simply a couple of 5mm diameter holes which run horizontally between the vertical heat breaks, and which are connected with vertical holes forming the inlet and outlet. After multiple hours of printing, the temperature of the coolant has never yet risen above about 27 deg C and the temperature inside the part of the heat breaks that are inside the cooling block never gets above about 45 deg C.

-

@deckingman @T3P3Tony thanks for you answers.

So i think my feeling was right and the cooling should be enough. -

@t3p3tony said in heatsink for watercooled hotend, dimensions?:

@cosmowave printing at PLA with a 0.4mm nozzle I have seen success with just a rubber tube around a thin wall tube as a heatsink. so its likely that a much smaller water contact surface will provide sufficient cooling, in comparison with an air-cooled hotend.

https://reprap.org/forum/read.php?152,824251 and in particular https://reprap.org/forum/file.php?152,file=105316 for example. Hard to imagine a smaller cold side heatsink.

-

@achrn yes that's the one!

-

@achrn holy sh.... this is really small and lightweight!

i think my design could also be a bit smaller...

But i'd like to keep my existing heatbreak, because it should be compatible with the air cooled system.

In the picture above you see, that the heatbreak is touching the pushfit. So i can't make the heatsink shorter.

I will thinking about to shorten the heatbreak a bit on the top side...thanks for the links!

-

@cosmowave said in heatsink for watercooled hotend, dimensions?:

I will thinking about to shorten the heatbreak a bit on the top side...

That'll have some more advantages, like less nozzle tilt

-

@o_lampe said in heatsink for watercooled hotend, dimensions?:

That'll have some more advantages, like less nozzle tilt

Yes, i know. That's the reason why i make this hotend.

-

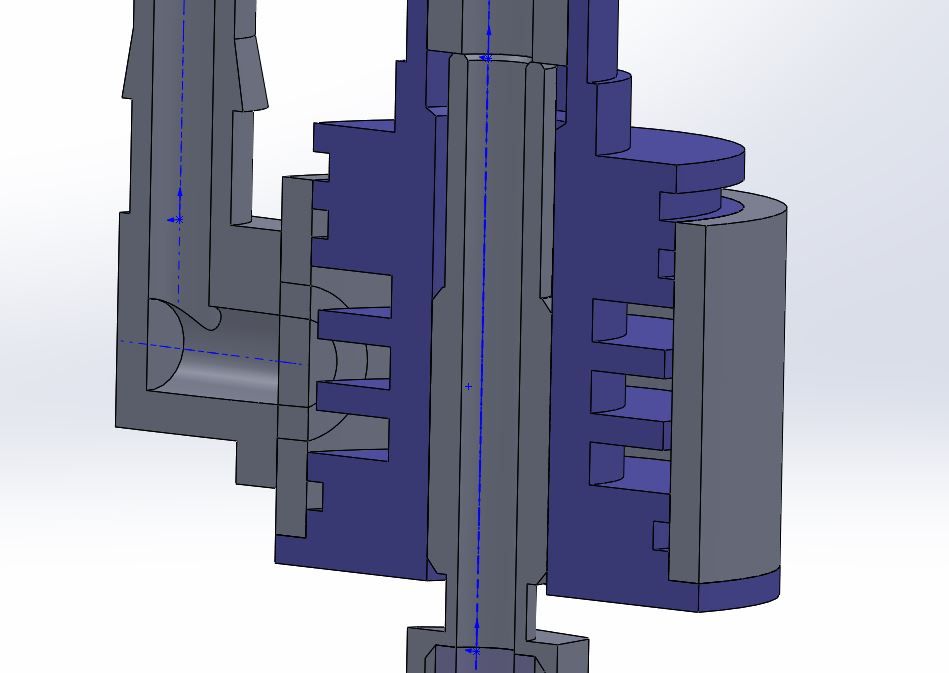

I see, that i can't make it much smaller with this concept.

My water In-Port needs nearly the space of the complete "cooling slot"!

-

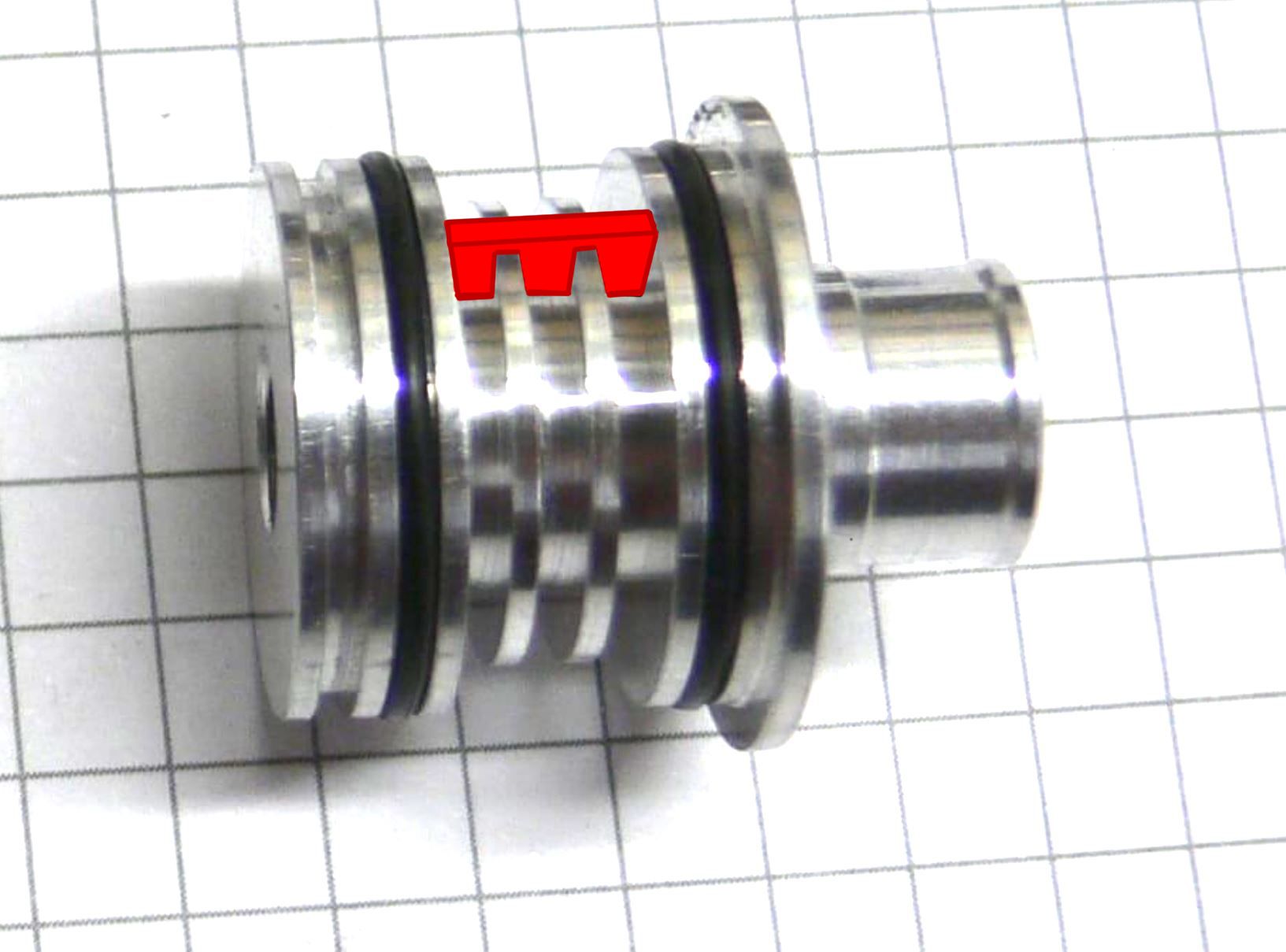

Sorry for answering to this old post. And this is only for info:

I have finished the work on my prototype watercooled hotend. Now it's ready to make first tests...

The heating block and heatbreak is from a DTO hotend.Here are some images

-

@cosmowave Are those brass barbs custom or off the shelf?

I am also going to do something very similar in future.

You might also consider this kind of barbs:

https://www.aliexpress.com/item/10000328905489.html?spm=a2g0o.order_list.0.0.1eb11802NQgtOw

or:

https://www.aliexpress.com/item/10000328986062.html?spm=a2g0o.order_detail.0.0.540843ceOvlKPDI've received those 2 weeks ago and seem pretty good quality.

-

I use a water cooled Phaetus Dragon in my BigDelta.

-

@mandragora said in heatsink for watercooled hotend, dimensions?:

Are those brass barbs custom or off the shelf?

They are more like custom. They were used as gearbox ventilation fitting in an old f1 car.

I have glued them in a carbon tube. They're from nitrated titanium, very light.

I try to reduce wheight on my effector (Delta). -

@cosmowave

Wouldn't it have been better to install the two connections opposite each other and not next to each other like here ?

Or are the two connections separated by a bridge so that the water has to go around the entire cooling fins ?I suspect when water pressure builds up there, the cooler water doesn't get everywhere, because water always takes the shorter route.

Sorry, I changed your photo to make it clear what I mean.Google Translate

----- Original Text -----Wäre es nicht besser gewesen die beiden Anschlüsse gegenüber zu verbauen und nicht wie hier nebeneinander ?

Oder sind die beiden Anschlüsse durch einen Steg getrennt so dass das Wasser um die gesamte Kühlrippen herum muss ?Ich vermute wenn sich dort ein Wasserdruck aufbaut, gelangt das kühlere Wasser nicht überall hin, denn Wasser nimmt immer den kürzeren Weg.

Sorry, ich habe mal Dein Foto verändert um deutlich zu machen was ich meine.

-

@norder Yes. You're right. It would be better to place the in/outlet on opposite sides. But i haven't the space for that.

I don't have "bridge" between the ports. But i'm sure, the cooling will be sufficient.