ZERO KELVIN HOTEND TEMP

-

@dc42 so ive restated it many times and its not shown the correct temp. ive tried deleting everything in config-overrid.g and anything that has to do with tunig if it appeared in config.g

so essentially im starting with a fresh install and its showing -273 still

-

@adalton5683 If you are sure that everything is configured correctly but you are still seeing-273, then did you read my post above (27th Jan @ 07:41) ?

-

@deckingman I think our timezones are off so I cant find a post at that time. so can you specify what post.

-

@adalton5683 said in ZERO KELVIN HOTEND TEMP:

@deckingman I think our timezones are off so I cant find a post at that time. so can you specify what post.

The first post after your opening posts.

-

@deckingman

Ok yeah I’ve already check that. The meter is giving me correct resistances on the therm. I did however order a new thermistor anyway just incase. Also checked and rechecked the crimps even checking their resistance. -

@adalton5683 try sending M308 S0 from the console with no other parameters. It will report the current parameters for sensor 0 and the last error recorded.

-

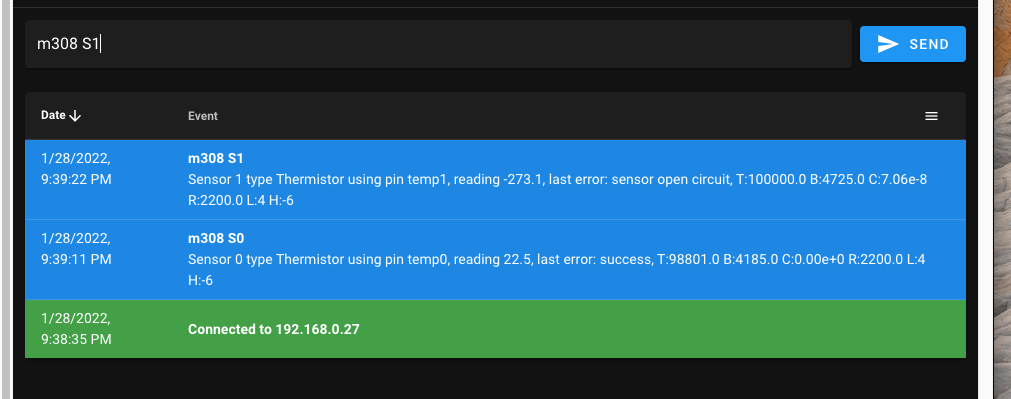

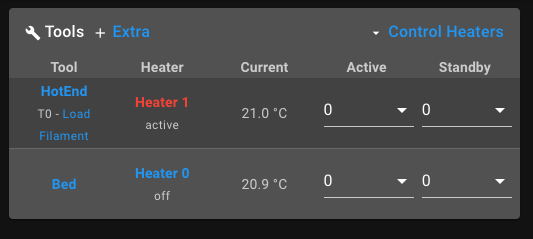

@dc42 I ran both S0 and S1

also my replacement thermistor arrived so I installed it, just the clipped end.

-

Can you switch from temp1 to temp2 connection on the board and update the M308 to reflect?

M308 S1 P"temp2" Y"thermistor" T100000 B4725 C7.06e-8

Does it still show -273?

Can you make up a much shorter lead for the thermistor to see if it's a break in the wiring?

-

1000 Thanks to you my friend! Your fix did not work bc i didnt try it but it did lend itsself to me finding my hot end thermistor plugged into out6 like a fan when I went to try it. I have no clue how it got there.

looks like its always anoob mistake .

-

So to to the devs, how well does this board handel CNC? ive got a couple CNC builds going rightnow and I ended up buying another one of these boards since I thought I toasted the heater/driver. So I will probably use this second board for a smaller 3 axis NEMA 17 cnc machine. hoping to power mostly everything but the spindle from it if possible.

I heard there is a CNC firmware. whos the main guy on that project?

My other build is a 12Nm NERMA34 4 axis, w/5hp spindle running with 110V in planning on using a rotary phase converter to hopefully get all 3hp out of that spindle. Im assuming this board cannot supply 6A ish per stepper right?

-

@adalton5683 Probably best to ask your CNC question in a new thread in the CNC forum for some more visibility.

https://forum.duet3d.com/category/28/cnc

And you can see some more details here: https://duet3d.dozuki.com/Wiki/Configuring_RepRapFirmware_for_a_CNC_machine