toolboard to match nema14 motors

-

Hi,

The 1LC format is nice to mount on a Hemera, but people use other extrusion systems as well ...it would be great to see other toolboard form factors like the pancake board to fit on the back of one of the currently popular mini extruders with round nema14s ... sadly I lack the time and skills to adopt the 1LC toolboard myself, but if anyone feels inspired, let me know (-:

PS: Yes, I know, chip shortage makes this hard.

-

Very nice project for those who knows electronics.

I am already using a 3 tool tolchanger and I am interested in upgrading it from duet2 to duet3 electronics.

If it was possible to make such a toolboard I would buy them and do the upgrade yesterday. -

@sigourosandreas yeah, similar, if that existed, I'd upgrade my IDEX yesterday ...

-

@oliof as I said. Design is easy... Chips not.

-

@oliof said in toolboard to match nema14 motors:

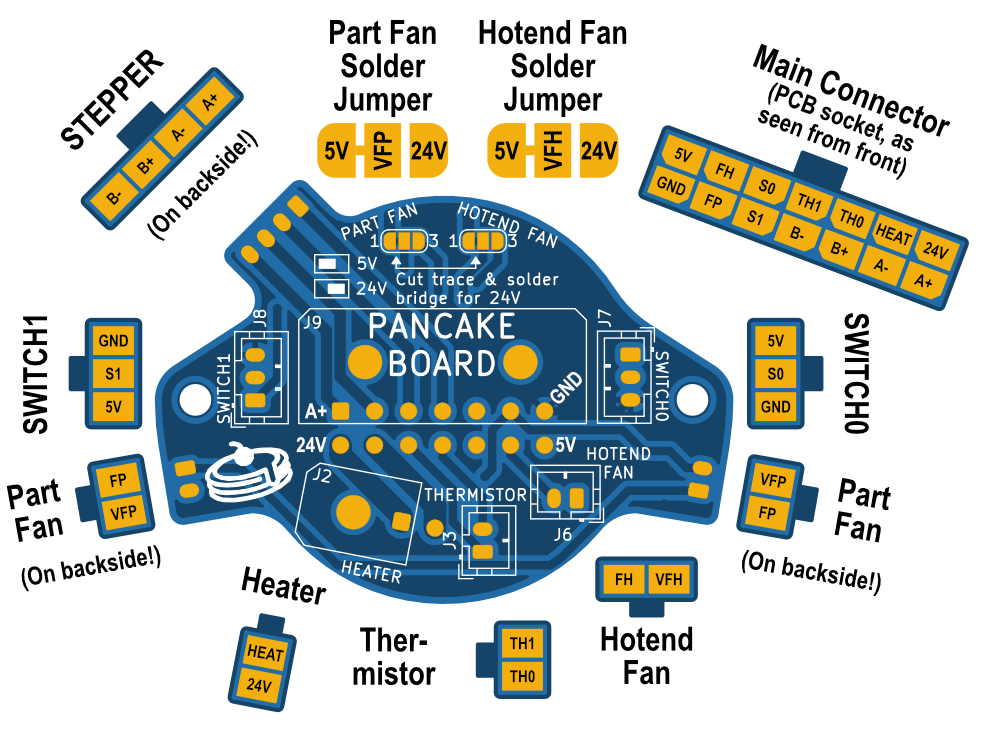

it would be great to see other toolboard form factors like the pancake board to fit on the back of one of the currently popular mini extruders with round nema14s

I don't think it is physically possible to pack all the 1LC electronics in to that small space; the 1LC is rather tightly packed, and that is smaller still.

However: What about a two-part design?

Use the pancake adapter concept but duplicate the Duet Smart Effector machine side connectors, and have a dedicated tool board to link to either adapter (counting the smart effector as an adapter) with the same two multiway plugs?

Or just a single easy-to-assemble multiway at the tool board end that can be wired as needed to either adapter board?

I like the toolboard concept, but apparently the latest revision come with loose 2mm connectors rather than pre-made ones?

I'd not inflict those one anyone by choice! Mine, happily, are V1.0 with screw terminals and pre-made connector tails. -

@rjenkinsgb maybe not everything on the 1LC is needed ...

-

For closure, the MKSTHR36 2040 based toolboard fills this gap in the product line-up. I will be able to report how it works probably end of next week.

-

@oliof did this work ok.

-

@R4ffers you will need to build your own version of the firmware, but it works. One thing to consider with the MKSTHR36 is that the heater output and fan0, as well as fan1 and fan 2, share a PWM channel, so they must have the same PWM frequency or one or the other won't work. Luckily I was able to just swap from fan0 to fan2 on my setup; but you could also just explicitly set the PWM frequency to be the same on each pair.

As a side note, as far as I was told, klipper does not have this issue because they aren't using hardware PWM, but since its easy to work around, I wouldn't say this behavior is a bug per se.

Edited to add: Since setting CAN addresses via Gcode does not work (yet) on the SB2040 based board, if you use multiple ones, you will need to set the address for each one in source code and then flash. This worked without a hitch on my IDEX printer using two toolheads (which is currently undergoing a revision of the print carriage for unrelated reasons).

-

@oliof Did you get the ADXL345 to work with input shaping?

-

@Th0mpy no, there is no ADXL support in mainline RRF, and I did not bother to switch to an STM board and use the fork that has ADXL support built in since I am using poorman's IS configuration on most systems (just set frequency to 43Hz and use ZVD) which gets me 90% of a fine tuned IS setup 90% of the time.

-

@oliof Unfortunate, but I understand. I ordered the 2040, two piece, for the Voron Stealthburner to play with. If I can get the 2040 working with the Duet 3, I was thinking about redoing the board to include the LIS3DH instead. It "should" be straightforward, but I'd like to first see the 2040 work.

Any pointers on compiling RRF for the 2040?

-

@Th0mpy the 3.5-dev branch of the Duet3Expansion project includes support for the RP2040.