Best IDEX nozzle wipe mechanisms?

-

https://github.com/KevinMar1/Pebble_Wiper

The pebble wiper looks like a winner.

-

@phaedrux wow that's a complicated solution.

I wipe on a silicone brush/sponge. It's more like a brush than a sponge, but it's advertised for use as a kitchen sponge, etc.

Some of them are not real silicone and will melt. You must find real silicone.

I've heard of such thing as actual silicone sponge which would be neat, but is elusive compared to the brush shapes commonly available.

Also, high-temperature felt-like cloth is used to wipe on lulzbot printers, and it works decently. I would ideally like a combination of the two but for now the silicone brush/sponge is nice.

One thing to keep in mind is that little bits of plastic can go flinging off the brush when it is wiped, so like... plastic bits will end up in belts, on linear rails, etc.

-

Our current solution: https://www.instagram.com/tv/CVV1HHylJlC

Hopefully that link works for non-Instagram users. It’s high temp felt which can withstand ~300c.

-

@oliof

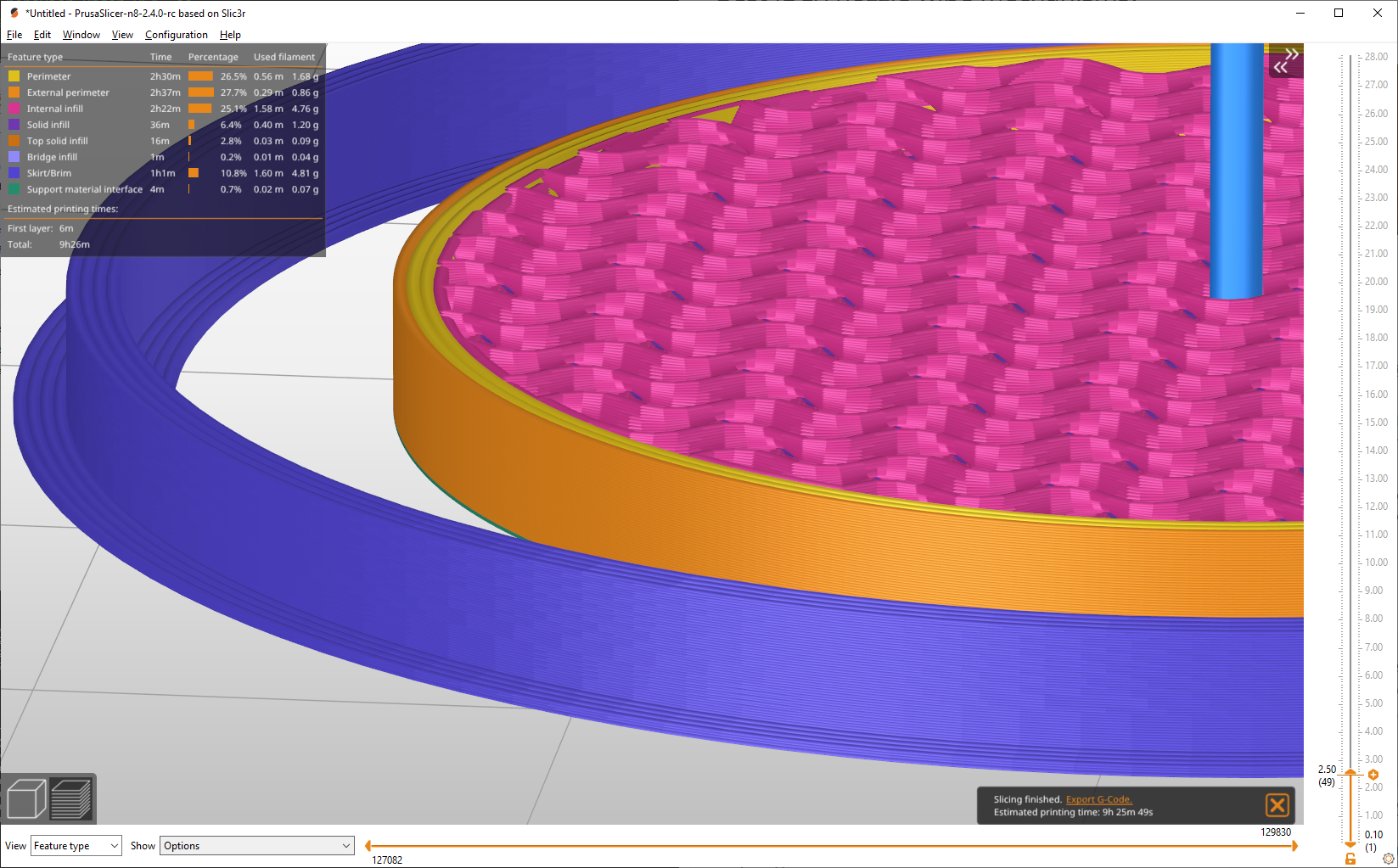

I started to use a full-height skirt (windshield option in PS) with a single perimeter. I didn't want to waste too much filament, but the skirt often kicked off the bed.

A wider skirt or a raft would help I guess.The main advantage is, that it's closest to the part (unlike the pebble wiper or silicone brushes).

The melt-chamber pressure is fully built up and there's less time to start oozing again.

-

@oliof I don't know if this will be much help but this is the latest iteration of my wipe/purge facility. https://www.youtube.com/watch?v=ppa1e_GClQ4&t=518s

My situation is a bit different to yours in that my main hot end has 6 inputs and as such, I have a need to purge filament as well as wipe the nozzle. I also have other hot ends where the nozzle is at a different position in the Z direction, so I need to be able to easily adjust the height of the wiper.

The silicone strip works well. I wipe the nozzle by moving it back and forth in the Y direction while also moving left to right in the X direction. In my case, the build plate moves in Z and the nozzle is in a fixed position. The challenge has always been how to mount the wiper so that it is in a fixed position relative to the nozzle while not interfering with the build plate. Anyway, it might give you some ideas....

-

@oliof I have the pebble wiper design installed and it works very well once you have it set up properly. Does it do more than any other purge and wipe tool? Maybe not.

I have an e3d tool changer with a couple of home made Orbiter / v6 hot end tools and a Hemera. The version I use is on a linear rail so that it can accommodate different size tools.

-

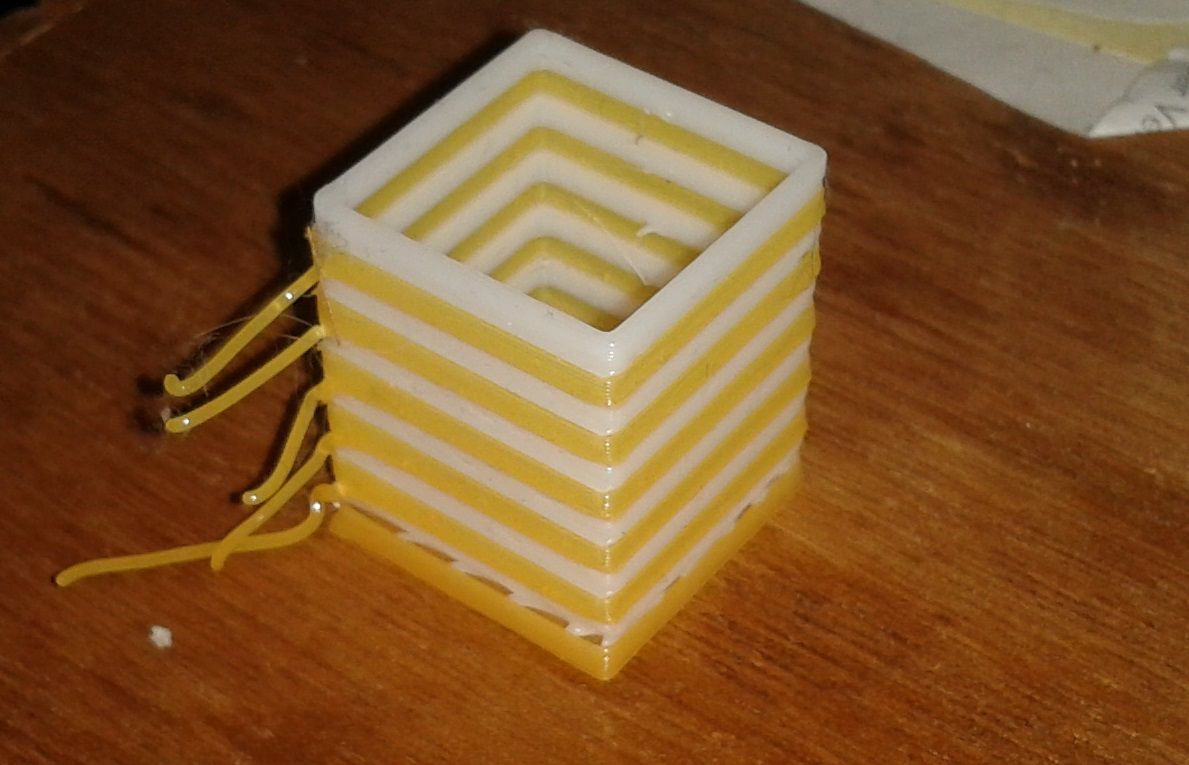

@o_lampe I do the same thing: use the tall skirt to purge (because even with perfect wiping, the nozzle needs to be primed or the first moves look crappy)

I had the same issue of the skirt being knocked off.

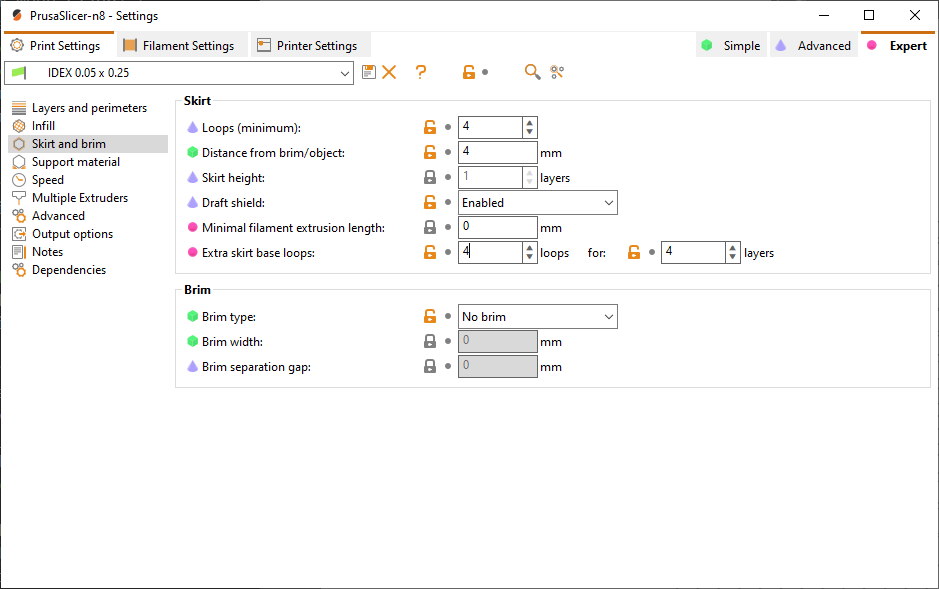

I modified prusaslicer to have a feature where you can add a brim essentially to the skirt, and you can add it for as many layers as you want.

https://github.com/n8bot/PrusaSlicer/releases

-

@bot

That's excellent! Did you start a pull request?

I couldn't use the 'official' wipe tower from PS, because my extruders had different nozzle sizes.[OT]

I have several slicer-related wishes, I can't fulfill on my own. Mainly related to hashPrinter's multi toolpath.

Do you think, the Prusa-gang has an open ear for wishes, their printers don't need? -

@o_lampe I have also never been able to use the wipe tower gizmo, but boy howdy did they put a lot of complicated effort in implementing that wipe tower and all its workarounds. The tall skirt works perfectly for me, and with the new base loop settings it adheres well too.

I love the Prusa team, but they are resistant to changes that come form outside, it seems.

I plan on maintaining my version as somewhat of a "community edition." I want to keep it as close to stock PS as possible, while providing the features and changes that the community wants, but that Prusa team is unwilling to implement.

Some of the changes I've made have ended up in stock PrusaSlicer (maybe coincidentally, or maybe I inspired them?). So, the goal is to have all changes merged in upstream, but if not we will maintain them.

However, I don't want to get swamped by feature creep -- for some things, we will send people to SuperSlicer to get the feature implemented.

This version is intended to be much closer to upstream Prusa, and we want to avoid any log4j-style feature creep scenarios.

This version is intended to be much closer to upstream Prusa, and we want to avoid any log4j-style feature creep scenarios.What feature(s) did you have in mind?

The prusaslicer issue tracker on GitHub is a great place to start the discussion -- if the prusa team is willing to implement something, that is always the best way to go. If not, we can carry on from the discussion there, so that things don't become fragmented.

My idea is to work 100% with the Prusa devs, not against them.

-

@bot said in Best IDEX nozzle wipe mechanisms?:

What feature(s) did you have in mind?

It's still unclear to me how the Duet team will implement the idea of multi-gcode streaming (and mini-Z axes on every extruder). But based on that, I'd like to try to print different objects simultaneously. Or have all four extruders work on the same object with collision detection.

A slicer and RRF would have to cooperate to synchronize print speed to have (almost) matching layer times.

It would also need a setup-option to link an object to a certain extruder (or two extruders to split infill/perimeter between different nozzles)

The wishlist is pretty long, it's actually a slicer of it's own kind. Otherwise I'd need several clever postprocessing plugins.[/OT]

Back to subject:

Scenario= single nozzle but several objects: do you think you could wrap the skirt(s) around single objects instead of going around the whole print area?