ghosting problem (extrusion width oscillating)

-

Hi,

I'm having issues with ghosting. Now that I'm analyzing the problem I realized, that it is probabely not the normal ghosting problem of oscillating x and y axes but rather a Extruder problem.

The ringing doesn't happen everywhere, for example 90° angles have almost no ghosting at all. It is more of a problem on wider angles (for which I don't have an explanation.

The actual problem can be seen on this image of a single wall ringing tower (aborted after ca 1cm)

As you can see, the axis movement looks quite stable but the extrusion width oscillates wildly, thus creating the ringing pattern. The picture above has been printed with 50mm/s speed, 1800mm/s2 acceleration, 15mm/s jerk, 0.2mm line height, 0.45mm line width.

My setup is a E3D Chimera hotend paired with two Bondtech BMG extruders and ca 75cm long capricorn bowden tubes. All the bowden connectors have collars and don't appear to be loose. The issue appears with both extruders but one seems more severe than the otherWhat I tried already

- different print speed (30mm/s and 50mm/s)

- setting pressure advance to 0

- different jerk values for extruder (10mm/s and 25mm/s)

- different acceleration values for extruder (1000mm/s2 and 3000mm/s2)

all those changes didn't affect the outcome other than that depending on the print speed the ripples are closer together or wider away which is understandable if the frequency stays the same.

Do you know what might be the reason for this strange behaviour?

Thank you very much in advance for your help! -

@jamkas Try and decouple the extruder from the XY movement by printing at the same speed in XY but at two different layer heights (like 0.2 and 0.3). how does that change the pattern.

-

@jamkas what is the geometry of your print head?

One of my machines has a severe Z axis oscillation triggered mostly by Y movement. This because the centre of mass of the print head is displaced in both Y and Z directions from the X rail, so that Y acceleration induces a torsional oscillation of the print head about the X rail. This Z axis oscillation will of course cause a corresponding oscillation in extrusion width.

You could mount an accelerometer on the print head to determine whether Z ringing is the cause of varying extrusion.

-

Thank you both for helping me!

@T3P3Tony printing in 0.1mm looked similar to the 0.2mm I used previously. 0.3mm is indeed slightly better but not very much.

@dc42 My printer has a crossed gantry, similar to an ultimaker. The print head is guided by two long LM8LUU bearings and the gantry (8mm rod) is guided by a MGW12 linear rail.

the accelerometer arrived just yesterday (luckily) and I screwed it to the print head (I was only able to attach it with two screws for now but it feels safely attached).

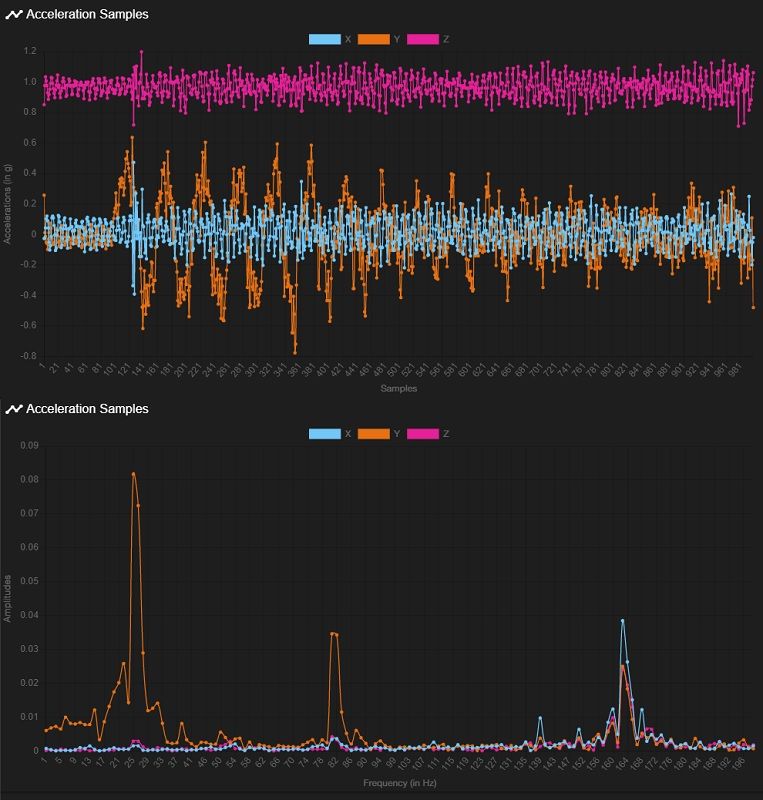

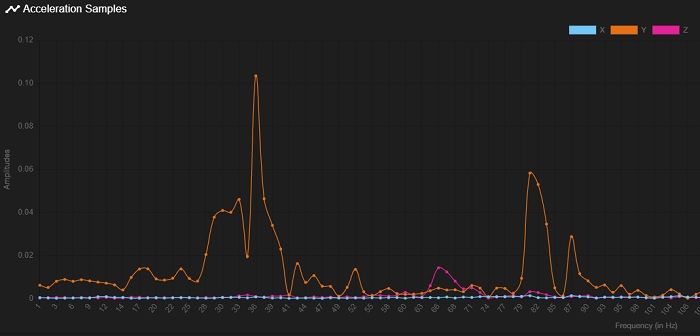

So today I installed it and did some experimenting. There I realized, the Y axis accelerates with much oscillation. I guess the peak at 26hz might be the culprit because (50mm/s)/(26hz) equals roughly 2mm which correlates quite well with the ripples.Here is the analysis of the movement in Y direction.

G1 X200 Y100

G4 S2

M956 P0 S1000 A0

G4 P10

G1 Y200 F3000

Movement in X direction doesn't have this 26hz peak.

G1 X150 Y150

G4 S2

M956 P0 S1000 A0

G4 P10

G1 X250 F3000

Also there is no 26hz oscillation right after moving stops.

G1 X200 Y100

G4 S2

G1 Y200 F3000

M400

M956 P0 S1000 A0):

Do you know any possible reasons for this behaviour?

-

@t3p3tony said in ghosting problem (extrusion width oscillating):

@jamkas Try and decouple the extruder from the XY movement by printing at the same speed in XY but at two different layer heights (like 0.2 and 0.3). how does that change the pattern.

please try this as well

-

@t3p3tony I printed the test piece in 0.1, 0.2 and 0.3mm. 0.1mm looks just as bad as 0.2mm. The 0.3mm print has slightly less pronounced ripples but it is still there.

-

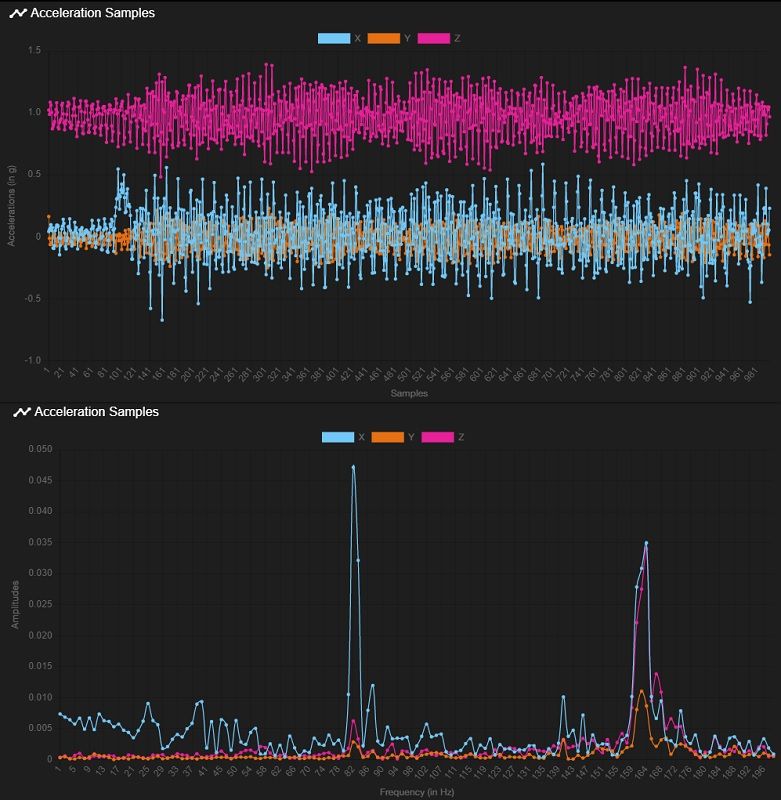

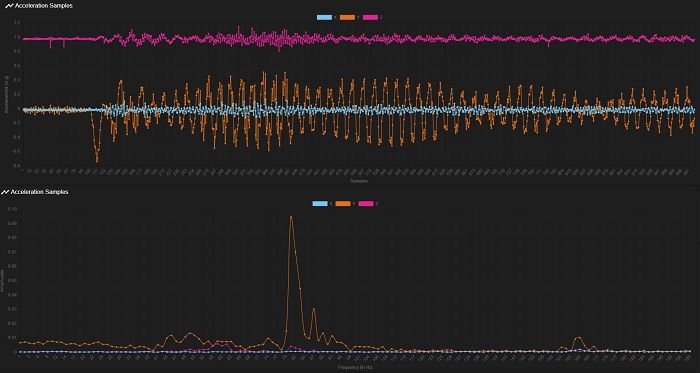

I did some more testing. This time I mounted the accelerometer on the rod which drives the printhead in the Y direction:

There the peak at 26hz is a lot less, hardly a problem anymore. On the other hand the oscillation at 82hz is much more prominent than on the print head.

I repeated the measurement on the other side of the rod which yielded quite the same result.

How is it possible that the print head amplifies the 26hz oscillation so much? At first I thought of a faulty linear bearing but I can't hear anything that sounds like a broken bearing. Could it be that a single long LM8LUU bearing is too short and I need to use two LM8UU for each axis on the print head instead?

Also, what might be the reason for the huge 82hz oscillation on the rod which drives the Y axis? some NEMA17 motor problem?I'm quite at a loss about this riddle and am really grateful for your valuable help! Thank you very much!

-

@jamkas with vibration issues like this there are two things at play. The excitation source that makes the structure vibrate, and the natural frequencies of the structure.

For ringing on prints, the excitation source is the sudden acceleration of the print head, which will generally excite a wide range of frequencies, but only for a short while. You will also get some constant(ish) excitement from the stepper motors etc which is what causes the noise on printers, but that's not what you are seeing here.

So you instead need to look at the natural frequencies of the machine and what those mode shapes look like. From what you're measuring, it seems that the 26Hz mode causes a response on the print head, but not the ends of the gantry. That likely means that it is a mode which only involves the print head moving. This could be the rods flexing (maybe the span length is different in the different axes, or do you use different bearings?). It could also be the cooling fans flapping. They look like they are much stiffer in one direction than the other and may weigh enough to cause to wobble. Other thought could be your hotend mounting. It's a Chimera by the looks of things so may have different mount stiffnesses in different directions.

Maybe try a few more tests with different parts taken off to see?

Re the 82Hz mode on the y block, it could be the stepper motor or belt meshing frequency or something else, especially if it doesn't decay on longer moves

Hope some of that helps!

-

@jamkas post a picture please. The point of the test is to see if the ripples occur at different spacing with different layer heights. If the problem is caused by the extruder (e.g. an eccentric drive gear) then the pulses will be spaced differently at different layer heights. if the problem is caused by the motion system then they will be in the same places no matter what the layer height.

-

So here is what I tried in the last few days:

- The ripples have the exact same spacing when printing with 0.1mm as with 0.3mm.

- The ripples are spread further apart if I speed up the print to 160% print speed

I interpret both of these results that the extruder is not at fault but instead it's something with the print head.

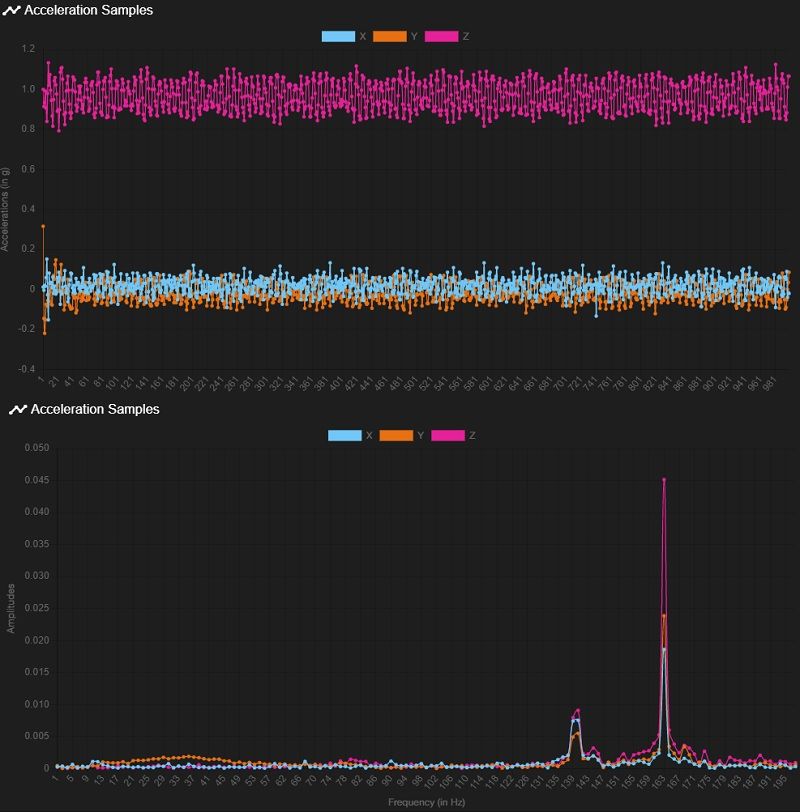

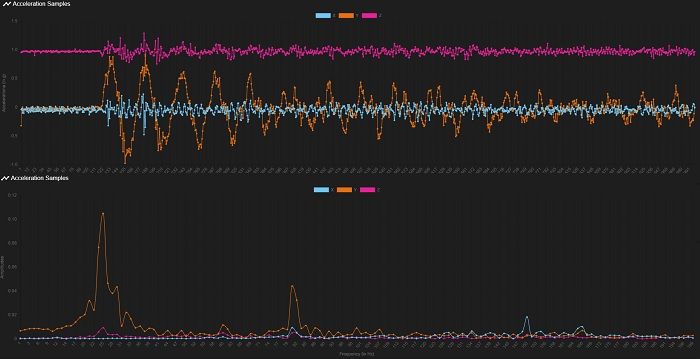

To tackle the 26hz vibrations, I tried to remove things from the print head. First the two fans on either side, then the blTouch. Both didn't change anything in this regard. Then I removed the hotend, leaving only the base with the two bearings. This shifted the vibration towards a higher frequency, peaking at 36hz.

Then I removed the print head entirely and put the accelerometer to the exact spot where the print head was on the rod that moves in Y-direction. There were no vibration around 26hz

Then I designed a completely new print head which was wider (two linear bearing in each axis instead of one) and with the hotend/bltouch higher up in order to get the center of mass closer to the rods. The result (completely assembled) was disheartening as it had the very same vibrations at 25hz as the old print head had.

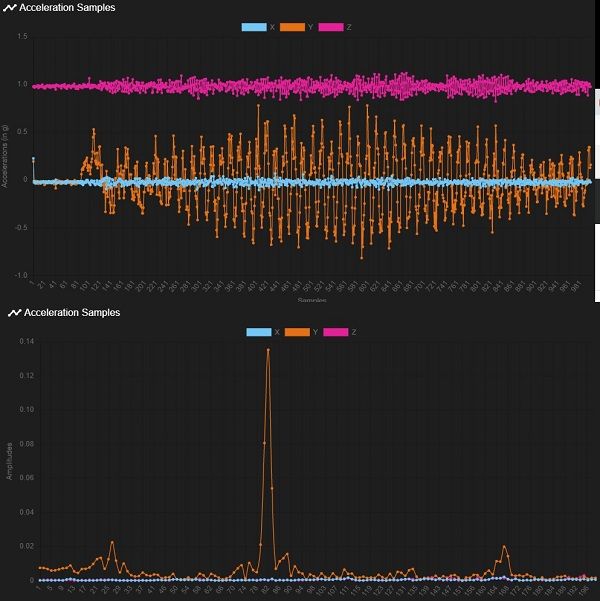

I'm now considering to create and test a setup with direct drive in order to see how a much heavier setup (with the extruder+motor on the print head) affects my situation.

Still I find it curious that it only affects movement in Y direction. The bearings are identical ones (LM8LUU), the rod along the X axis (driving the movement in y direction) is 556mm long, the other one only 450mm but as both are 8mm diameter hardened steel and the print head is quite light I feel like they shouldn't flex enough to cause my problems.Now to the 80hz oscillation: I read on this site that GT2 belts should be tensioned to 6-8 pounds which is 26.6-35-5 Newton. I measured the tension on my setup acoustically using the android app "BeltTensionMeter". There I learned that my belts were at around 80-90N. Seems I had a slightly wrong feeling about how tense it should be when I set up the system... So I re-tensioned all belts to the recommended 35N. Then, to make the motors run even more smoothly, I changed microstepping for X and Y axes from 64 to 128 microsteps.

Sadly, both changes didn't affect the 80hz oscillations at all.Currently, I don't consider the 80hz to be a big problem. The visible ripples on my prints are 2mm apart if I print with 50mm/s print speed (as good as I can measure it...). This correlates very much with my 26hz problem as (50mm/s)/(26/s) = 1.9mm. The 80hz would produce 0.625mm wide ripples at 50mm/s and I don't see any of that kind on my prints.