How to make Prusa Slicer work

-

Good morning, as you maybe have read in my pervious post I'm having problems with Ideamker slicer because I can't set at all the PA and it's beaving in a weird way placeing the seam.

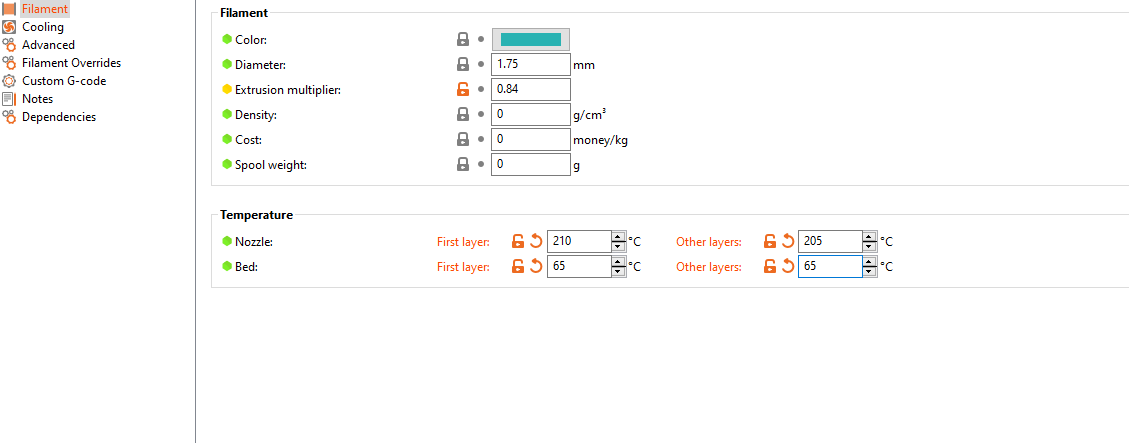

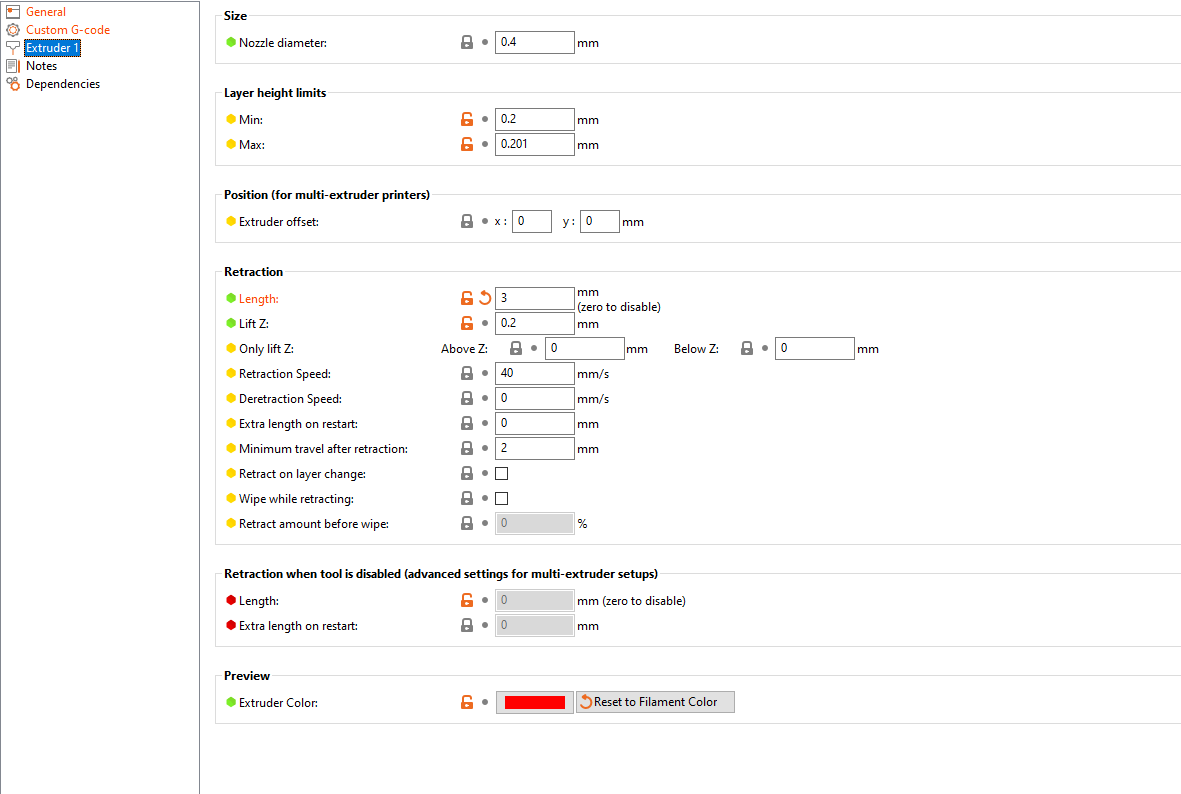

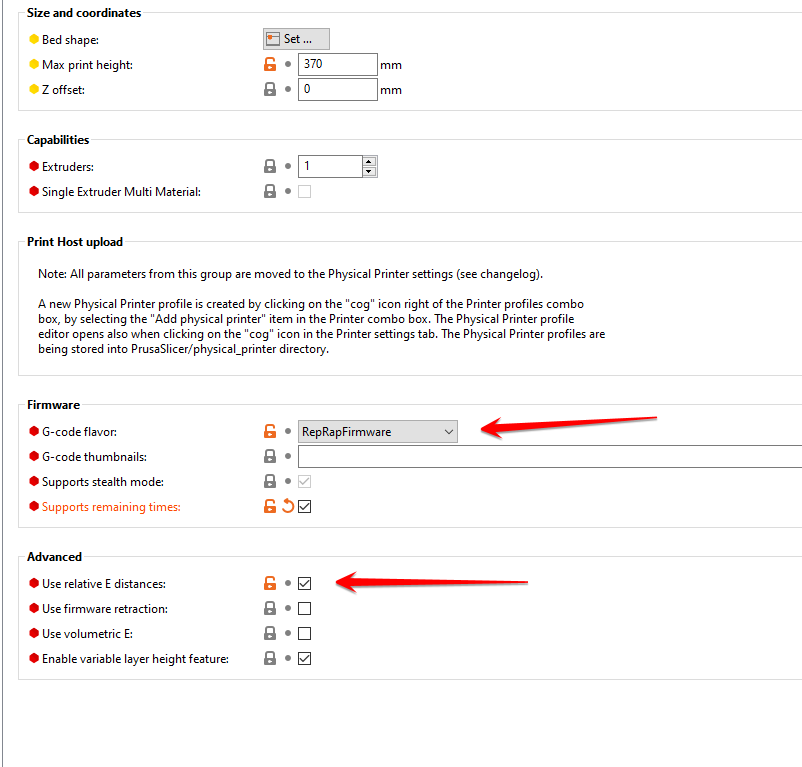

I would like to use Prusa Slicer to see if the problem is slicer-related or in some way printer-related....With PrusaSlicer I'm exeperiencing the issue that the extrusion amount is very very very poor, almost no filament come out the nozzle....of course I'm missing some settings, here's my settings, what am I doing wrong?:

here's my start GCODE:

M104 S[first_layer_temperature]; set extruder temp M140 S[first_layer_bed_temperature]; set bed temp M109 S[first_layer_temperature]; wait for extruder temp M190 S[first_layer_bed_temperature]; wait for bed temp M83 ; relative extrusion mode M98 P"Print_gcodes/print_pla_pressure_advance.g" ;pressure advance T0 M98 P"Print_gcodes/print_start_gcode.g" ; start gcode operationsprint_pla_pressure_advance.g is an empty file for now

and this is print_start_gcode.g:

M106 P11 S100 H-1 ; Turns on LED Stripe G28 XY ;Home XY M561 ; Clear any bed transform that might be in place G1 X165 Y165 ; Move Probe to middle of bed G30 ; Do a single probe G29 S1 ; load height map M201 E500.00:500.00 ; Set extruders acceleration ; ============================================== G1 Z1.0 F3000 ; move z up little to prevent scratching of surface ;----------------------------------------------------- G1 X1 Y10 Z0.3 F5000.0 ; move to start-line position G1 X1 Y250.0 Z0.3 F1500.0 E22 ; draw 1st line ;----------------------------------------------------- G1 X1.3 Y250.0 Z0.3 F5000.0 ; move to side a little G1 X1.3 Y10 Z0.3 F1500.0 E22 ; draw 2nd line G1 E-2 F3000 ; retract filament 2mm G92 E0 ; reset extruder ; ============================================== G1 Z1.0 F3000 ; move z up little to prevent scratching of surfacep.s.

even changing from relative to absolute "E dsitance" nothing changes -

@the_dragonlord in the filament settings: extrusion multiplier 1.0

-

@wejrijo said in How to make Prusa Slicer work:

@the_dragonlord in the filament settings: extrusion multiplier 1.0

no changes

-

@the_dragonlord said in How to make Prusa Slicer work:

@wejrijo said in How to make Prusa Slicer work:

@the_dragonlord in the filament settings: extrusion multiplier 1.0

no changes

-

@wejrijo said in How to make Prusa Slicer work:

@the_dragonlord said in How to make Prusa Slicer work:

@wejrijo said in How to make Prusa Slicer work:

@the_dragonlord in the filament settings: extrusion multiplier 1.0

no changes

Thank you but I know well how to set and calibrate my printer....with Ideamaker and Simplify3D I have no extrusion issue, only with PS

-

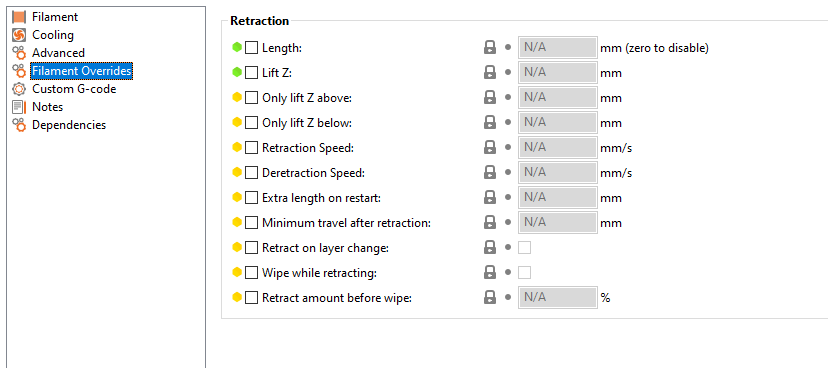

@the_dragonlord Look at the Filament Override tab

-

@pcr said in How to make Prusa Slicer work:

@the_dragonlord Look at the Filament Override tab

empty....

-

@the_dragonlord said in How to make Prusa Slicer work:

with Ideamaker and Simplify3D I have no extrusion issue, only with PS

Slice the same very simple model (like a three-layer solid square) and read the gcode to see if they are all consuming the same amount of filament?

I note that in the gcode snippet up thread, your first two lines each extrude 22mm of filament over a 240mm line, that's 52.9mm3 of material, so should be laying down a 0.22mm2 line of extrusion, which if nozzle is at 0.3mm off the bed should be 0.7mm wide. If you're not getting that, it looks like a printer problem, not a slicer problem.

-

@achrn said in How to make Prusa Slicer work:

@the_dragonlord said in How to make Prusa Slicer work:

with Ideamaker and Simplify3D I have no extrusion issue, only with PS

Slice the same very simple model (like a three-layer solid square) and read the gcode to see if they are all consuming the same amount of filament?

I note that in the gcode snippet up thread, your first two lines each extrude 22mm of filament over a 240mm line, that's 52.9mm3 of material, so should be laying down a 0.22mm2 line of extrusion, which if nozzle is at 0.3mm off the bed should be 0.7mm wide. If you're not getting that, it looks like a printer problem, not a slicer problem.

The two lines come out perfectly, the problems start with the sliced GCODE

-

@achrn said in How to make Prusa Slicer work:

@the_dragonlord said in How to make Prusa Slicer work:

with Ideamaker and Simplify3D I have no extrusion issue, only with PS

Slice the same very simple model (like a three-layer solid square) and read the gcode to see if they are all consuming the same amount of filament?

I note that in the gcode snippet up thread, your first two lines each extrude 22mm of filament over a 240mm line, that's 52.9mm3 of material, so should be laying down a 0.22mm2 line of extrusion, which if nozzle is at 0.3mm off the bed should be 0.7mm wide. If you're not getting that, it looks like a printer problem, not a slicer problem.

Here are the first layers of a simple cube sliced with ideamaker:

;PRINTING: default-box.3mf ;PRINTING_ID: 0 G1 F2400 E-3.0000 G0 F9000 X155.292 Y155.292 ;TYPE:WALL-OUTER ;WIDTH:0.585 G1 F1500 E3.0000 G1 F2400 X164.708 Y155.292 E0.6321 G1 X164.708 Y164.708 E0.6321 G1 X155.292 Y164.708 E0.6321 G1 X155.292 Y155.292 E0.6321 G0 F9000 X156.462 Y156.462 ;PRINTING_TIME: 13 ;REMAINING_TIME: 202 ;LAYER:1 ;Z:0.500 ;HEIGHT:0.200 M106 S255 G4 P200 M106 S255 M104 T0 S205 ;PRINTING: default-box.3mf ;PRINTING_ID: 0 M82 M98 P"Print_gcodes/pressure_advance_at_layer_change.g" M83 G0 F900 Z0.500 G0 F9000 X155.225 Y155.225 ;TYPE:WALL-OUTER ;WIDTH:0.450 G1 F600 X164.775 Y155.225 E0.3288 G1 X164.775 Y164.775 E0.3288 G1 X155.225 Y164.775 E0.3288 G1 X155.225 Y155.225 E0.3288 G0 F9000 X156.125 Y156.125 ;PRINTING_TIME: 17 ;REMAINING_TIME: 198 ;LAYER:2Here are the same file sliced with PS:

;LAYER_CHANGE ;Z:0.44 ;HEIGHT:0.2 M98 P"Print_gcodes/pressure_advance_at_layer_change.g" G1 Z0.440 F7200.000 G10 S205 ; set temperature G1 X160.200 Y169.800 ;TYPE:External perimeter ;WIDTH:0.4 G1 F900.000 G1 X160.200 Y160.200 E0.28504 G1 X169.800 Y160.200 E0.28504 M73 P15 R2 G1 X169.800 Y169.800 E0.28504 G1 X160.260 Y169.800 E0.28325 G1 E-3.00000 F2400.000 G1 Z0.640 F7200.000 G1 X160.342 Y161.178 G1 Z0.440 G1 E3.00000 F2400.000 ;TYPE:Solid infill ;WIDTH:0.456468 M73 P16 R2 G1 F3600.000 G1 X160.995 Y160.525 E0.03177 G1 X161.580 Y160.525 E0.02011 G1 X160.525 Y161.580 E0.05131 G1 X160.525 Y162.165 E0.02011 G1 X162.165 Y160.525 E0.07975 G1 X162.749 Y160.525 E0.02011 G1 X160.525 Y162.749 E0.10819 G1 X160.525 Y163.334 E0.02011 G1 X163.334 Y160.525 E0.13663 G1 X163.919 Y160.525 E0.02011 G1 X160.525 Y163.919 E0.16507 G1 X160.525 Y164.504 E0.02011 G1 X164.504 Y160.525 E0.19351 G1 X165.089 Y160.525 E0.02011 G1 X160.525 Y165.089 E0.22195 G1 X160.525 Y165.674 E0.02011 G1 X165.674 Y160.525 E0.25039 G1 X166.259 Y160.525 E0.02011 G1 X160.525 Y166.259 E0.27883 G1 X160.525 Y166.843 E0.02011 G1 X166.843 Y160.525 E0.30727 G1 X167.428 Y160.525 E0.02011 G1 X160.525 Y167.428 E0.33572 M73 P17 R2 G1 X160.525 Y168.013 E0.02011 G1 X168.013 Y160.525 E0.36416 G1 X168.598 Y160.525 E0.02011 G1 X160.525 Y168.598 E0.39260 G1 X160.525 Y169.183 E0.02011 G1 X169.183 Y160.525 E0.42104 G1 X169.475 Y160.525 E0.01006 G1 X169.475 Y160.817 E0.01005 G1 X160.817 Y169.475 E0.42104 G1 X161.402 Y169.475 E0.02011 G1 X169.475 Y161.402 E0.39260 G1 X169.475 Y161.987 E0.02011 G1 X161.987 Y169.475 E0.36416 G1 X162.572 Y169.475 E0.02011 G1 X169.475 Y162.572 E0.33572 M73 P18 R2 G1 X169.475 Y163.157 E0.02011 G1 X163.157 Y169.475 E0.30728 G1 X163.741 Y169.475 E0.02011 G1 X169.475 Y163.741 E0.27884 G1 X169.475 Y164.326 E0.02011 G1 X164.326 Y169.475 E0.25040 G1 X164.911 Y169.475 E0.02011 G1 X169.475 Y164.911 E0.22196 G1 X169.475 Y165.496 E0.02011 G1 X165.496 Y169.475 E0.19352 G1 X166.081 Y169.475 E0.02011 G1 X169.475 Y166.081 E0.16507 G1 X169.475 Y166.666 E0.02011 G1 X166.666 Y169.475 E0.13663 G1 X167.250 Y169.475 E0.02011 G1 X169.475 Y167.250 E0.10819 G1 X169.475 Y167.835 E0.02011 G1 X167.835 Y169.475 E0.07975 G1 X168.420 Y169.475 E0.02011 G1 X169.475 Y168.420 E0.05131 G1 X169.475 Y169.005 E0.02011 G1 X168.822 Y169.658 E0.03178 M106 S127.5They are completely different from each other.....

-

@the_dragonlord Here's what happens:

-

@the_dragonlord said in How to make Prusa Slicer work:

They are completely different from each other.....

They aren't expected to be the same.

Also, I note your Prusa example has a skirt, apparently with curves at the corners, so that muddies the waters. There's also reference to pressure advance in teh code, but I don't think that's more than a red herring.

Your ideamaker cube has this:

G0 F9000 X155.292 Y155.292 ;TYPE:WALL-OUTER ;WIDTH:0.585 ... G1 F2400 X164.708 Y155.292 E0.6321 G1 X164.708 Y164.708 E0.6321 G1 X155.292 Y164.708 E0.6321 G1 X155.292 Y155.292 E0.6321So that is simple squares, the nozzle moving 9.416mm to a side and using 0.6321mm of filament. That's 0.161mm2 extrusion.

The Prusaslicer cube has this

G1 X160.200 Y169.800 ;TYPE:External perimeter ;WIDTH:0.4 ... G1 X160.200 Y160.200 E0.28504 G1 X169.800 Y160.200 E0.28504 ... G1 X169.800 Y169.800 E0.28504 G1 X160.260 Y169.800 E0.28325So that is simple square, the nozzle moving 9.600mm to a side and using 0.28504mm of filament. That's only 0.072mm2 extrusion

The comments say the Prusa is a thinner wall, but only 10% thinner. Pro-rata both to 0.45 thick would bring the Prusa up to 0.0805mm2.

So the Prusa is delivering half as much filament (curiously, exactly half as much) for some reason. However, I'm suspicious that the Prusa is delivering what it should - a 0.4 x 0.2 mm extrusion should be 0.4x0.2=0.08mm2. Have you, long ago, put some correction factor into the other slicers for some reason?

With a factor of exactly two I'd start to wonder if a 400 step stepper was swapped for a 200, and 'fixed' by putting an extrusion multiplier in? As per previous poster's suggestion, I'd go back and check calibration and configuration of the extrusion hardware from fresh, but you didn't like that suggestion.

-

@achrn said in How to make Prusa Slicer work:

G0 F9000 X155.292 Y155.292 ;TYPE:WALL-OUTER ;WIDTH:0.585 ... G1 F2400 X164.708 Y155.292 E0.6321 G1 X164.708 Y164.708 E0.6321 G1 X155.292 Y164.708 E0.6321 G1 X155.292 Y155.292 E0.6321So that is simple squares, the nozzle moving 9.416mm to a side and using 0.6321mm of filament. That's 0.161mm2 extrusion.

Aha, but I've just noticed that further down it has

0 F900 Z0.500 G0 F9000 X155.225 Y155.225 ;TYPE:WALL-OUTER ;WIDTH:0.450 G1 F600 X164.775 Y155.225 E0.3288 G1 X164.775 Y164.775 E0.3288 G1 X155.225 Y164.775 E0.3288 G1 X155.225 Y155.225 E0.3288Which is much closer to the Prusa case. I don't jknow what that slicer is doing there. I still think teh GCode from Prusa is calling for about teh right amount of material.

-

@achrn said in How to make Prusa Slicer work:

@the_dragonlord said in How to make Prusa Slicer work:

They are completely different from each other.....

They aren't expected to be the same.

Also, I note your Prusa example has a skirt, apparently with curves at the corners, so that muddies the waters. There's also reference to pressure advance in teh code, but I don't think that's more than a red herring.

Your ideamaker cube has this:

G0 F9000 X155.292 Y155.292 ;TYPE:WALL-OUTER ;WIDTH:0.585 ... G1 F2400 X164.708 Y155.292 E0.6321 G1 X164.708 Y164.708 E0.6321 G1 X155.292 Y164.708 E0.6321 G1 X155.292 Y155.292 E0.6321So that is simple squares, the nozzle moving 9.416mm to a side and using 0.6321mm of filament. That's 0.161mm2 extrusion.

The Prusaslicer cube has this

G1 X160.200 Y169.800 ;TYPE:External perimeter ;WIDTH:0.4 ... G1 X160.200 Y160.200 E0.28504 G1 X169.800 Y160.200 E0.28504 ... G1 X169.800 Y169.800 E0.28504 G1 X160.260 Y169.800 E0.28325So that is simple square, the nozzle moving 9.600mm to a side and using 0.28504mm of filament. That's only 0.072mm2 extrusion

The comments say the Prusa is a thinner wall, but only 10% thinner. Pro-rata both to 0.45 thick would bring the Prusa up to 0.0805mm2.

So the Prusa is delivering half as much filament (curiously, exactly half as much) for some reason. However, I'm suspicious that the Prusa is delivering what it should - a 0.4 x 0.2 mm extrusion should be 0.4x0.2=0.08mm2. Have you, long ago, put some correction factor into the other slicers for some reason?

With a factor of exactly two I'd start to wonder if a 400 step stepper was swapped for a 200, and 'fixed' by putting an extrusion multiplier in? As per previous poster's suggestion, I'd go back and check calibration and configuration of the extrusion hardware from fresh, but you didn't like that suggestion.

Thanks for your answer, in Ideamaker I haven't made any adjustment on the stepper steps/mm or some kind of multiplier...It not I didn't liked the suggestion, it's that they are all steps that I've made right now and I'm sure that in Ideamaker I have no firmware overrides about step/mm or so on...I've just made several thin wall tests to get the exact extrusion multiplier for all my filaments....I really don't know what's happening....even with Simplify3D it all gone well...only with PS there are problems...

-

@the_dragonlord How did you tune your extruder steps/mm set in config.g? If it involved something that used your slicer you may have in effect tuned for that. What value do you have set for steps/mm in your config.g file and what extruder are you using?

-

@gloomyandy said in How to make Prusa Slicer work:

@the_dragonlord How did you tune your extruder steps/mm set in config.g? If it involved something that used your slicer you may have in effect tuned for that. What value do you have set for steps/mm in your config.g file and what extruder are you using?

415 step/mm, original bondtech BMG

-

@the_dragonlord Assuming that has a standard 1.8 degree stepper (does it?), that sounds fine.

-

@gloomyandy said in How to make Prusa Slicer work:

@the_dragonlord Assuming that has a standard 1.8 degree stepper (does it?), that sounds fine.

it sound because it is fine

with other slicers I have no problems

with other slicers I have no problems -

Is the first layer height the same? Same width and flow rate?

-

@the_dragonlord I've used PS for years with issues so am slightly perplexed by your issue!

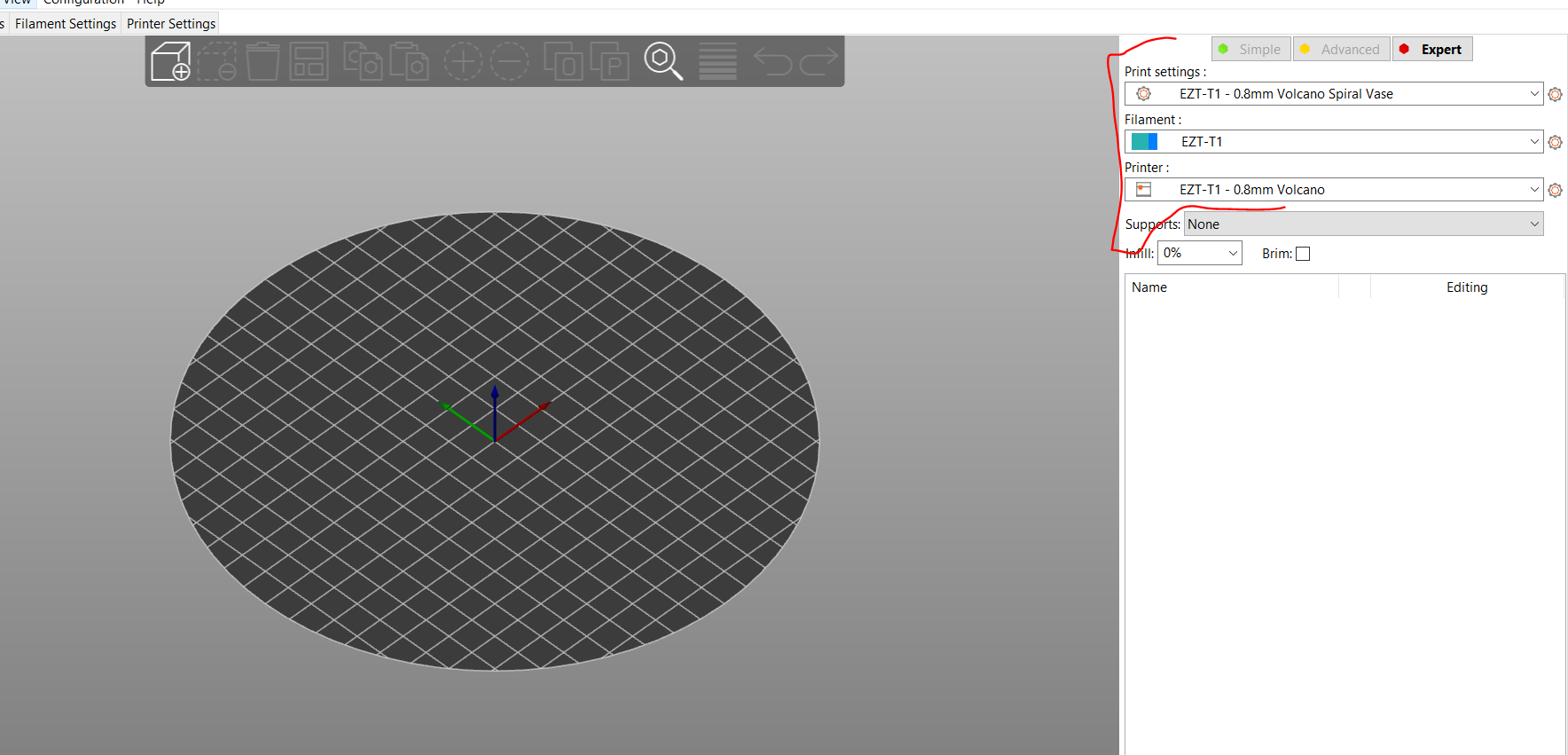

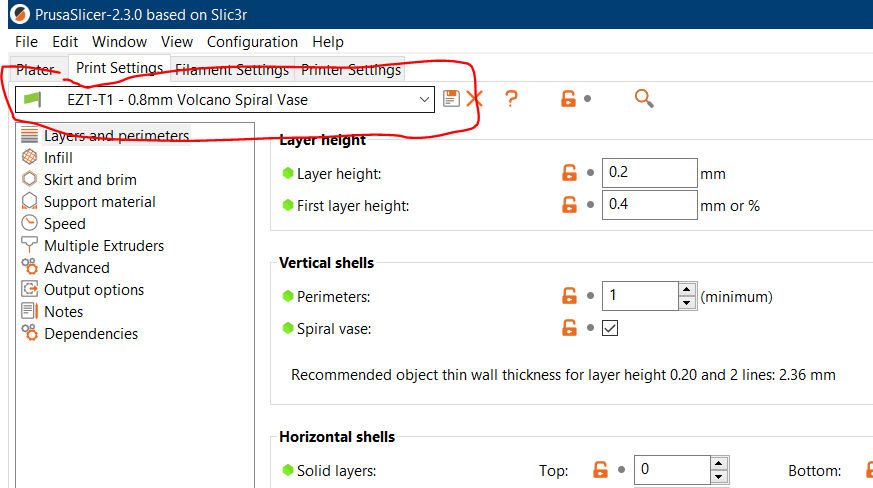

One thought - are the filament/printer/print profiles that you're editing the ones that PS is using to slice the file? I.E. Do these:

Match these:

Could simply be that you're actualy slicing with one of the default 2.85mm profiles?

Failing that, if you can export your config from PS (File, Export, Export config), post it here and I can try it on mine to see what's up. Might need to rename the filetype to .txt to upload it to the forum