z probe on kossel linear plus anycubic

-

Good Evening everyone, or rather early morning as I write this.

I just put a Duet wifi onto a stock Anycubic Kossel Linear Plus.

This machine uses a switch for the z probe....

I was following Danal's excellent guide, up until he left the firmware at 2.xxx

Then I moved on to 3.xxx

My sticking point is the configurator for Z probe.

I just don't know what to select

I tried to do normal Z, inverted Z, e0stop, inverted e0stop.

Nothing works though.

There was some talk of rewiring the Z switch but I would prefer to have it work with just config changes at this time.

Can anyone suggest the proper settings for this Anycubic Kossel Linear Plus?

I have the Z probe into the e0 port on the board.

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Thu Jun 10 2021 00:41:52 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Martin" ; set printer name M665 R135.4 L271.5 B105 H250 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E96.00 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop ; Z-Probe M558 P5 C"^!zprobe.in" H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z15.65 ; set Z probe trigger value, offset and trigger height M557 R85 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S90 ; set temperature limit for heater 0 to 90C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S250 ; set temperature limit for heater 1 to 250C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S0 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0:1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory T0 ; select first toolm115 FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.1.1 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2020-05-19b2 -

M558 P5 C"^!zprobe.in"

Change the zprobe.in to e0stop if that's the pin you're using.

Or am I missing something?

@bahnstormer said in z probe on kossel linear plus anycubic:

FIRMWARE_VERSION: 3.1.1

Also a good idea to update to 3.2.2

https://github.com/Duet3D/RepRapFirmware/releases/download/3.2.2/Duet2and3Firmware-3.2.2.zip -

@phaedrux said in z probe on kossel linear plus anycubic:

M558 P5 C"^!zprobe.in"

Change the zprobe.in to e0stop if that's the pin you're using.

Or am I missing something?Thank you very much for replying!

Which combination of drop down choices from the configurator would give me that result?

Or is this a custom code I'd have to enter?

-

To update the topic -

@Phaedrux suggestion worked. I now show Z probe 0 and when pressed, z probe 1000However, during auto calibration, the head crashes into the bed

If I press the z stop with my finger early, i see it goes to 1000 in teh webcontrol, but it still tries to crash into the bed, and I have to kill the power. Any thoughts there?As to why the whole problem started:

It seems like the Configurator, the wiki and the firmware are not quite in sync with each other.

So you can use the configurator, get sort of close by guessing as it doesn't tell you what all the drops downs mean, then you have to manually edit the config file yourself.

-

@bahnstormer said in z probe on kossel linear plus anycubic:

Which combination of drop down choices from the configurator would give me that result?

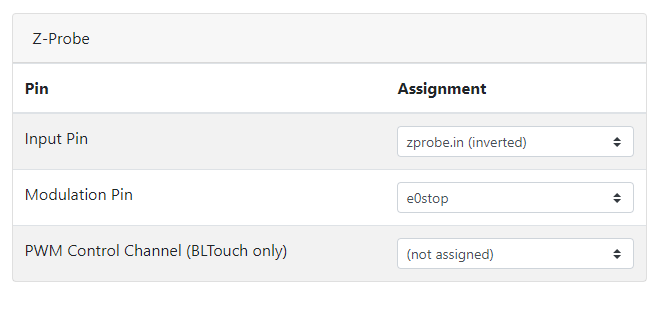

Set the input pin to e0stop and the modulation pin to none. Most types of Z probe don't use a modulation pin.

-

@dc42 unfortunately not possible from the drop down

here's a screen shot of my options:

only under the modulation pin drop down is the e0stop available. Is this a bug in the configurator?

-

Yes that doesn't seem to be intentional. There is a major overhaul to the config tool coming soon. Thanks for bringing that to our attention.

The config tool as it is now is limited to begin with, so the intention has always been that it gets you a starting point for syntax and command layout and then you would go through the customization process for your actually printer and doing the testing and commissioning to get it all working correctly.

-

@phaedrux awesome look forward to the new version.

If you can I would write

" the intention has always been that it gets you a starting point for syntax and command layout and then you would go through the customization process"

at the start of the configurator for other new users like me who assume that it is 100% all you need