Toolboard wather cooling

-

I am in the process of upgrading my E3d toolchanger to Duet3. I have developed extra water-cooled extruder tools for the duet2. (If all goes well I can share the complete system in a few months).

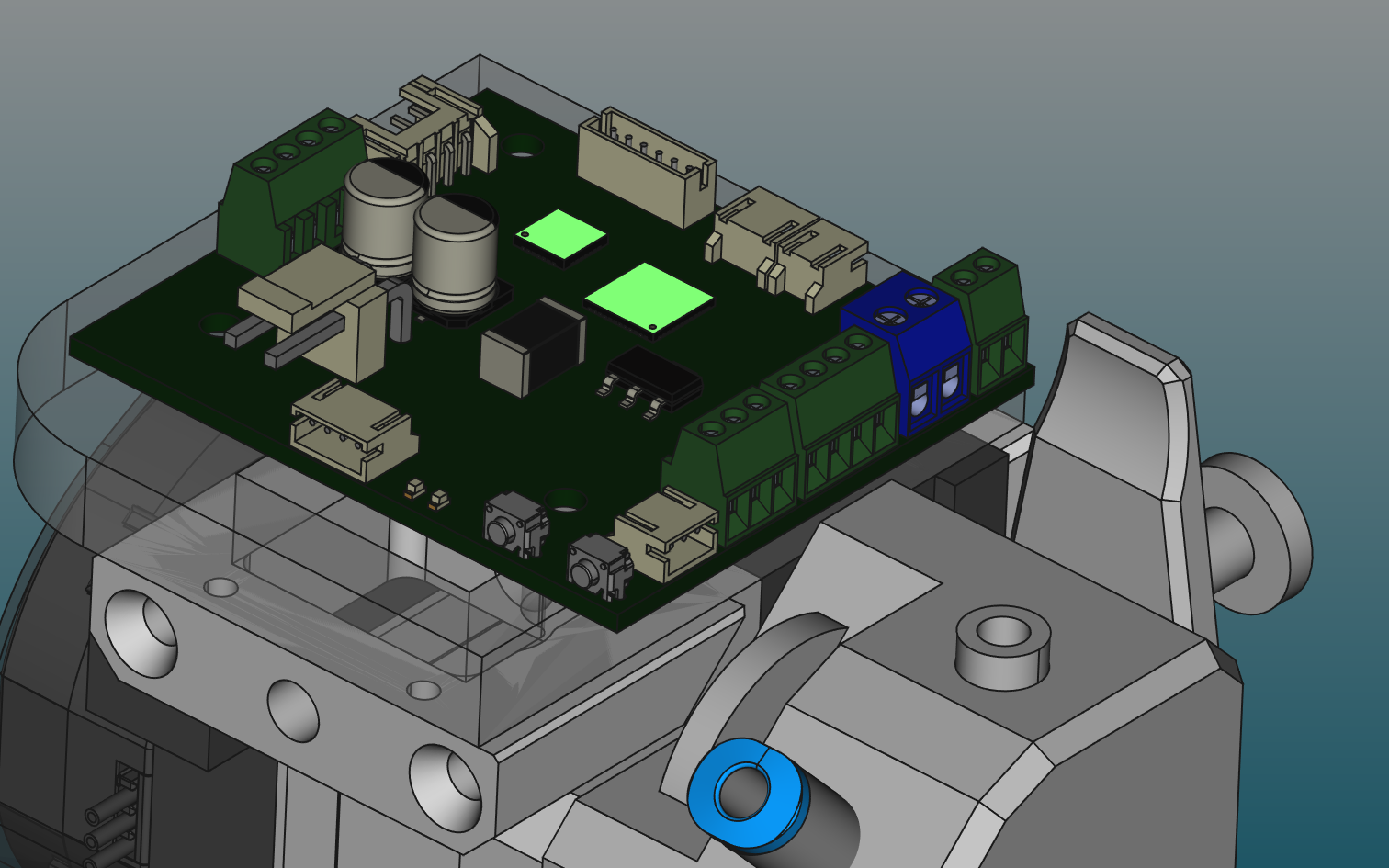

Now that the Duet3 has a toolboard, I am in the process of integrating the board into the extruder tool:

Is it enough to actively cool the driver (0) with water (according to the data sheet: 125 degrees junction temperature), or is that not necessary at all?I see that the processor should work up to 85 degrees according to the data sheet. So I don't think it needs additional cooling.

I assume that the mosfet doesn't need any additional cooling either.

Would be super happy to get feedback and advice on the components. Do you have any experience?

At the moment, I'm mainly printing with PET, where I've evaluated an optimal room temperature of around 40 degrees for my system. It may well be that in the future it will also be 60 or even 70. Who knows what else will be printed there.

*Edit:

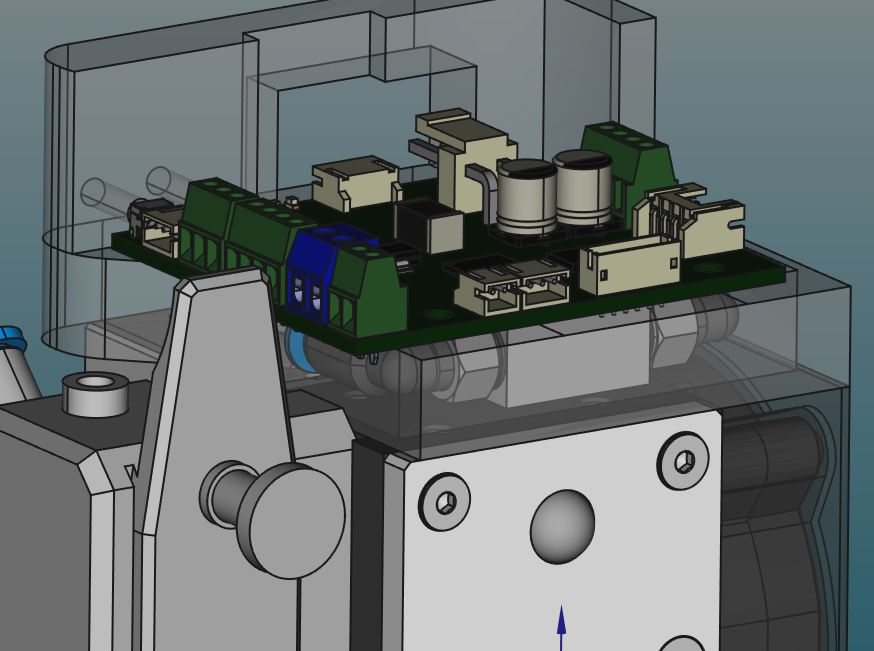

As I see, the driver and controller are pretty close, so super easy to cool both:

-

@metty, if you will be printing with a chamber temperature of 60 or 70C, then cooling the tool board would be a good idea.

I suggest you use a water-cooled aluminium block underneath the tool board, and a thin electrically insulating sheet (e.g. mica washer) between that block and the underside of the tool board. The block should make contact (through the washer) with the underside of the PCB at least around the stepper driver (small square), microcontroller (large square), and 5V regulator (the chip with 3 legs and a tab that is at one corner of the processor).

There is no need to cool the top, because the chips and PCB are designed to dissipate the heat via the underside of the PCB.

-

@dc42 Thanks! So i will continue like this:

-

Just FYI, we run toolboards in actively heated enclosures up to 80c without issue.. but water cooling would be quite the trick!