HELP...SSR With Heater Channel on 3CH daughterboard

-

So, I thought I understood how to set everything up correctly, but here I am.

So reading some other threads, it sounded like you could use the "heater channel" for a hotend to trigger your SSR to turn on a bed or enclosure, or in my case, I need to do both independently.

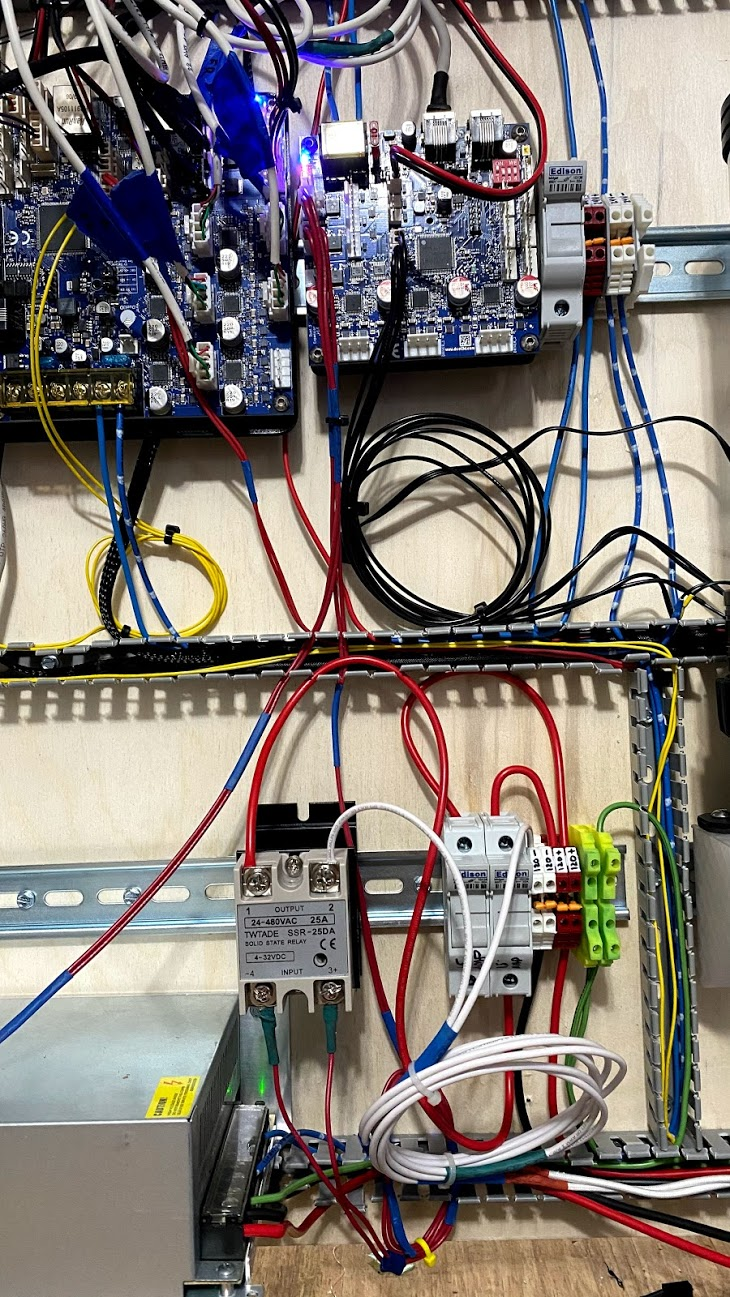

Here is a picture of what I have, it just keeps giving a heater fault when trying to turn on the bed heater, I've switched around polarity and I haven't been successful yet.

Heater "1.out_1" (daughterboard) is being used to trigger the relay. I'm running 24V VIN.

Here is the exact relay I am using: SSRI am using the same wiring setup as the diagram except that the input side of the SSR is on "1.out_1" as previously mentioned.

Just need the guidance to get this online.

Thanks.

-

Does the LED indicator on the SSR light up when you send the command to turn on your bed?

Do you see any temp rise in DWC? Or does it fault immediately?

What temp does your thermistor say in DWC at idle? -

@alex-cr It faults right away. The temp it gives is 22.5C. Just double-checked again, it does not turn the light on.

-

Post your config.g file. If you run M98 P"config.g" do you get any errors?

I just had a bad experience with ignoring the errors coming out of it because I thought I knew better, cost me a couple days...

-

@alex-cr I think your on to something, this makes sens sensor #0 and 3 not being configured, I was too ignoring them

What do I need to do to fix it?; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Apr 19 2021 17:15:29 GMT-0400 (EDT); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E145.51:145.51 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X400 Y400 Z440 S0 ; set axis maxima; Endstops

M574 X1 S1 P"io1.in" ; configure active-high endstop for low end on X via pin io1.in

M574 Y2 S1 P"io0.in" ; configure active-high endstop for high end on Y via pin io0.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M558 P5 C"^io3.in" H15 F1200 T6000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:400 Y50:400 S50 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"1.out1" T0 ; create bed heater output on 1.out1 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp2" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin temp2

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S455 ; set temperature limit for heater 1 to 455C

M308 S2 P"temp3" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp3

M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 2 to 280C

M308 S3 P"temp1" Y"thermistor" T10000 B4723 C1.19622e-7 ; configure sensor 3 as thermistor on pin temp1

M950 H3 C"1.out0" T3 ; create chamber heater output on 1.out0 and map it to sensor 3

M307 H3 B1 S1.00 ; enable bang-bang mode for the chamber heater and set PWM limit

M141 H3 ; map chamber to heater 3

M143 H3 S90 ; set temperature limit for heater 3 to 90C; Fans

M950 F0 C"!out4" Q25000 ; create fan 0 on pin !out4 and set its frequency

M106 P0 C"FRONT PANEL" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"!out5" Q25000 ; create fan 1 on pin !out5 and set its frequency

M106 P1 C"RAD 1 (TOP)" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on

M950 F2 C"!out6" Q25000 ; create fan 2 on pin !out6 and set its frequency

M106 P2 C"RAD 2 (BOTTOM)" S1 H1 T45 ; set fan 2 name and value. Thermostatic control is turned on

M950 F3 C"1.out6" Q500 ; create fan 3 on pin 1.out6 and set its frequency

M106 P3 C"Water Pump" S1 H-1 ; set fan 3 name and value. Thermostatic control is turned on

M950 F4 C"out7" Q500 ; create fan 4 on pin out7 and set its frequency

M106 P4 C"E3D V6 Hotend" S0.5 H2 T45 ; set fan 4 name and value. Thermostatic control is turned on; Tools

M563 P0 S"Mosquito Liquid" D0 H1 F-1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"E3D V6" D1 H2 F-1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings

M584 X0 Y1 Z3:4:5 E4 ; three Z motors connected to driver outputs 2, 5 and 6

M671 X-25.298:200.199:427.12 Y2.021:430.231:20.21 S0.5 ; ball screws at front left, back middle and front rightM308 S10 P"1.temp0" Y"thermistor" T10000 B3988 A"Coolant Cold" ; Configure coolant sensor cold side

M308 S11 P"1.temp1" Y"thermistor" T10000 B3988 A"Coolant Hot" ; Configure coolant sensor hot side; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@jordan_miller41 said in HELP...SSR With Heater Channel on 3CH daughterboard:

M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"1.out1" T0 ; create bed heater output on 1.out1 and map it to sensor 0I think the problem might be that your temp sensor for this heater is defined as being plugged into the 6HC while your output is set on the 3HC.

Is this supposed to be the case?

Edit: I just read down further, can you move your coolant sensors over to the main board and your control thermistors over to the 3HC?I believe the firmware requires that temperature sensors that control heaters be plugged into the same board. It will need to be confirmed though.

if your temp sensor is actually plugged into temp0 on the 3HC try changing the P command to the following:

P"1.temp0"By the way it looks like a similar change will be needed for your chamber heater on H3.

Edit: I just read down further, can you move your coolant sensors over to the main board and your heater control thermistors for H0 and H3 over to the 3HC?

-

@alex-cr Ahhhhh that makes sense, I will do that in the morning. I think that would have to be it, didn't even think of that. I'll report back tomorrow with hopefully good results!

-

@jordan_miller41 see the second bullet point at https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitations.

-

@dc42 thank you, that clears it up!

-

@dc42 So got the thermisters remapped, the SSR kicks on and started heating the bed up, then it just faulted again after heating the bed from 18C to 30C. Only stays on for about 30-45 seconds. Thoughts?

-

Have you performed an M303 command to get the heating model updated?

BTW you may have to do this manually depending on what firmware version you are currently running.

-

@alex-cr ok what if it is for bang-bang mode? So I have to tune the bed before it will heat all the way up?

-

PID tuning is recommended so that the firmware has an idea of the heaters performance (heat up and cool down time). In bang-bang it can be too slow for the default watchdog and it times out.

-

@phaedrux understood, so for an enclosure heater, is there a way to adjust the "watchdog" parameters? I don't know how long it will take to heat my enclosure and I don't want it to time out.

-

@jordan_miller41 said in HELP...SSR With Heater Channel on 3CH daughterboard:

is there a way to adjust the "watchdog" parameters?

Yes, PID tune the heater.

-

@phaedrux ok