G32 Delta z-probe not hitting low enough on some points

-

@jules-0, increase the H parameter (dive height) in the M558 command on config.g.

-

ty for your quick response and awsome support

first off all here is my config and firmware version

FIRMWARE_NAME: RepRapFirmware for Duet 3 Mini 5+ FIRMWARE_VERSION: 3.2.2 ELECTRONICS: Duet 3 Mini5plus WiFi FIRMWARE_DATE: 2021-02-11; Configuration file for Duet 3 Mini 5+ (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat Apr 17 2021 00:31:41 GMT+0200 (Midden-Europese zomertijd) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Delta" ; set printer name M665 R177.42 L356.8 B135 H284.40 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P1.0 S1 ; physical drive 1.0 goes forwards M569 P1.1 S1 ; physical drive 1.1 goes forwards M569 P1.2 S1 ; physical drive 1.2 goes forwards M569 P0.0 S1 ; physical drive 0.0 goes forwards M584 X1.0 Y1.1 Z1.2 E0.0 ; set drive mapping M350 E32 I0 ; configure microstepping without interpolation M350 X64 Y64 Z64 I1 ; configure microstepping with interpolation M92 X320.00 Y320.00 Z320.00 E873.08 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1400 Y1400 Z1400 E800 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"!1.io0.in" ; configure active-high endstop for high end on X via pin !1.io0.in M574 Y2 S1 P"!1.io1.in" ; configure active-high endstop for high end on Y via pin !1.io1.in M574 Z2 S1 P"!1.io2.in" ; configure active-high endstop for high end on Z via pin !1.io2.in ; Z-Probe M558 P8 C"^!1.io5.in" R1.0 H5 F300 T1800 ; set Z probe type to switch and the dive height + speeds + 500ms delay (R) M558 H30 G31 P500 X0 Y0 Z0 ; set Z probe trigger value, offset and trigger height M557 R135 S20 ; define mesh grid ; Heaters M308 S0 P"1.temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin 1.temp0 M950 H0 C"1.out0" T0 ; create bed heater output on 1.out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp0 M950 H1 C"out0" T1 ; create nozzle heater output on out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 S0 H1 T45 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off M950 F2 C"1.out3" Q500 ; create fan 2 on pin 1.out3 and set its frequency M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0:1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings M555 P5 ;Set Compatibility ; Miscellaneous M501 ; load saved parameters from non-volatile memoryhomedelta.g

; homedelta.g ; called to home all towers on a delta printer ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Thu Apr 15 2021 14:39:33 GMT+0200 (Midden-Europese zomertijd) G91 ; relative positioning ;*** Slow homing has been configured. Change F180 to F1800 below when your configuration is working G1 H1 X315 Y315 Z315 F1800 ; move all towers to the high end stopping at the endstops (first pass) G1 H2 X-5 Y-5 Z-5 F1800 ; go down a few mm ;*** Slow homing has been configured. Change F180 to F360 below when your configuration is working G1 H1 X10 Y10 Z10 F180 ; move all towers up once more (second pass) G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred G90 ; absolute positioning G1 X0 Y0 F6000 ; move X+Y to the centrebed.g

; bed.g ; called to perform automatic delta calibration via G32 ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Thu Apr 15 2021 14:39:33 GMT+0200 (Midden-Europese zomertijd) M561 ; clear any bed transform G28 ; home all towers ; Probe the bed at 6 peripheral and 3 halfway points, and perform 6-factor auto compensation ; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g. G30 P0 X0 Y134.9 H0 Z-99999 G30 P1 X116.83 Y67.45 H0 Z-99999 G30 P2 X116.83 Y-67.45 H0 Z-99999 G30 P3 X0 Y-134.9 H0 Z-99999 G30 P4 X-116.83 Y-67.45 H0 Z-99999 G30 P5 X-116.83 Y67.45 H0 Z-99999 G30 P6 X0 Y67.4 H1 Z-99999 G30 P7 X58.37 Y-33.7 H0 Z-99999 G30 P8 X-58.37 Y-33.7 H0 Z-99999 G30 P9 X0 Y0 H1 Z-99999 S6 ; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors ; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed)maybe im totally missing something (probably), after changing the endstops a bit i got now the third point also touching the bed and then the rest fails.

atleast its checking that it may be to low to trigger z-probe only thing is now that its working against me

#learning your duet3

-

mmmmmm

maybe reading was also hard for me; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g.lets try that first

-

so after following these steps https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe#Section_Calibrate_the_Z_probe_trigger_height

im getting this as output

im certain of it that im doing something wrong here. also checked the steps per mm by checking the Z with a caliper but they are fine, jogging - 5 mm is 5 mm when measuring.

well its still monday but im getting ready to grab a beer and call it for today

-

I think there must be a sensitivity issue with your piezos. -30mm trigger height is nonsensical assuming you set Z0 with the nozzle touching the bed.

-

what i did was placing a paper on the build plate, moved the nossle close to it. send command G92 Z0, moved up 5 mm. and did a G30 S-1 and got this as a result.

Still heard and saw the nossle hitting the bed. tommorow i will play with the sensitivity of the piezo PCB -

It may also help to increase your dive speed (M558 F600 perhaps) to make for a harder tap to trigger the piezo.

-

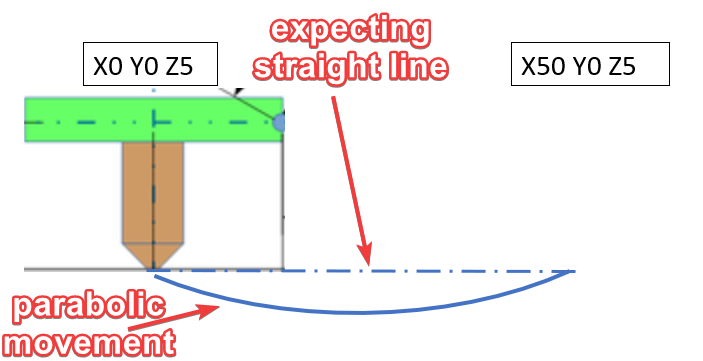

so after some manual calibration using the escher3d wizard, i saw some stange movement and no qlue to where the problem may be coming from.

hope some smart guys here can take a look on what might be wrong and point me into the right direction?so what im seeing that between moves, even jog moves the nossle dives down and comes up again when closing to the specific coordinates

my first impression is that my rod lengt or radius is way out of line,but after measuring again the rod length as good as i can its the same value in the config

-

-

If you use a Z probe then the Z motors must be connected to the main board. This is planned to be fixed in release 3.4.

-

Endstop switches and Z probes connected to the main board cannot control motors on an expansion board. This is planned to be fixed in release 3.4.

is this maybe limiting me right now?

the expension board is doing all the movement (XYZ), endstop, z-probe and bed temperature. the main board is going to be used only for Extruders and heaters -

-

Maybe. What are you using for hardware? You didn't mention you had an expansion.

-

my main board is a duet mini 5+ in SBC mode with a 3HC expension board doing all the XYZ movements, endstops, z-probe en bed heating

well in the top post i mentioned im using a 3HC board

i shall try to rewire everything to the mini 5+ board and see whats happens then.

-

@jules-0 said in G32 Delta z-probe not hitting low enough on some points:

my main board is a duet mini 5+ in SBC mode with a 3HC expension board doing all the XYZ movements, endstops, z-probe en bed heating

well in the top post i mentioned im using a 3HC board

i shall try to rewire everything to the mini 5+ board and see whats happens then.

The current firmware has a limitation: a Z probe cannot be used to control motors connected to expansion boards. So I think this explains the problem, and it should work when you connect the motors to the main board. We are currently working to remove that limitation.

-

@jules-0 said in G32 Delta z-probe not hitting low enough on some points:

well in the top post i mentioned im using a 3HC board

So you did.

-

@Phaedrux I hope I didn't offended u, I'm super grateful u guys thinking with me

-

@jules-0 said in G32 Delta z-probe not hitting low enough on some points:

@Phaedrux I hope I didn't offended u, I'm super grateful u guys thinking with me

Not at all.

-

we got results,

i rewired everything to the mini 5+, uploaded a config without the 3HC board and G32 works right out of the box (btw i never mentioned im running a Delta)

so my initial design was to have the mini 5+ at the top of the delta. to be able to plug what ever tool i may think of in the future without opening the bed and the 3HC board to be under the bed doing all the XYZ movement endstop z probe things. making it so that only 2 cables are going up and down (can and 24 Volt).

the design is a D-Force Delta witch has its main board under bed.

well for now im going to stick to the mini 5+, if u need beta testers for 3.4 i would gladly give it a shot

-