Two Precision Piezo boards in parallel on one input possible?

-

@neodue said in Two Precision Piezo boards in parallel on one input possible?:

May as an explanation on why I tried my luck with the bed sensors

I would not agree they are "bad". Piezo is what it is. IMHO the sensors created by precisionpiezo Andromeda and Orion are pretty good (much better IMHO than stand-alone disks where the puny force on the wires will detach them from the disk along with a piece of disk coating)

Most issues I have (and you have as well from what I see) are the way we are using the technology. When you use the way they designed it, it works out of the box

Due to the restraints I have with my printer, a head sensor would be quite difficult to implement without losing a very significant amount of motion length. The hotend is mounted between the two y axes which are horizontally aligned in opposite to most other printers, with just barely enough space to let the tooth belt through:

I disagree with you here

and I have to say, I disagree without ANY proof

and I have to say, I disagree without ANY proof  but I am somehow sure that there is a way to incorporate a piezo-like sensor in this type of head mount without losing more than 5mm of Z space. Now, I'm "pretty sure" cause I made a bunch of piezo modified carriers for my printers so from that experience I think I'm right but without actually designing and testing I can't be 100% sure... but 95% ... now while I'm 95% sure I could design it, I'm not sure it would be FDM printable, you might have to send it to SLS printer but that might be an acceptable solution (I printed my main head on SLS, the whole x-carriage + extruder is custom designed and printed on SLS, would probably be rather expensive but I had a way to do it for free so I used it)

but I am somehow sure that there is a way to incorporate a piezo-like sensor in this type of head mount without losing more than 5mm of Z space. Now, I'm "pretty sure" cause I made a bunch of piezo modified carriers for my printers so from that experience I think I'm right but without actually designing and testing I can't be 100% sure... but 95% ... now while I'm 95% sure I could design it, I'm not sure it would be FDM printable, you might have to send it to SLS printer but that might be an acceptable solution (I printed my main head on SLS, the whole x-carriage + extruder is custom designed and printed on SLS, would probably be rather expensive but I had a way to do it for free so I used it) but since I actually gave up as even the cheap aliexpress bltouch knockoff give results that are consistent and repeatable, do not require thorough nozzle clean before probing and work "every time" ...Now back to the problem:

What I can say from my experiments is that a full bed mesh not working is definitely a problem with sensors canceling out each other, even if this effect might be somewhat related to the impulse the touch of the hotend nozzle creates as you say.That is weird. I had a similar idea myself at the beginning, luckily I have 4ch scope (both digital and analog storage) and I looked at the signal from 3 and 4 andromeda's directly without amp and in my case they don't cancel out. The issue is just in how "sharp" the "touch" is in my case.

For e.g. this is the test that works for me

- use 3 andromeda's on 3 corners of the bed

- probe bed, ~20% of the bed around 4th corner is untestable

- take a wooden skewer stick (3mm dia 20-30cm long wooden pick) and release it from 2-3cm distance from your hand to hit the bed with a tip, every time this is detected properly

- take the same skewer and touch the bed and press it down, you can press it for 3-4cm before it triggers, there's nothing on any of the 3 sensors on the scope except noise

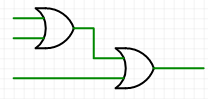

Now, if you see that they are canceling themselves, get yourself 3 separate amps feed the output of them to a 3 input or gate .. something like SN74LVC1G332 or if you have issues with smd you can bodge something with regular dual or gates just link them together

using something trough hole like https://www.digikey.com/en/products/detail/texas-instruments/CD4072BE/67317

Hitting harder does not help much up to a certain point - which I would have difficulty reaching with the rather slow z axis of my printer, and I also fear for my glass printing plate...

are you using latest beta? as all older versions do not probe using speed you set but slower.

As soon as I unplug the sensor(s) I suspect to cancel out the signal (i.e. no mechanical change at all, I only remove the corresponding cable from the amplifier) I get a wonderful signal for the part of the bed that was previously too insensitive. This would not happen if it was a purely a lack of contact impulse the setup would suffer from.

So that is what I want to exploit.

If you really have them cancel themselves that's the easiest one to solve, three el-cheapo amps with 3 input or gate and bob's your uncle... I use something similar on a machine taht's not 3d printing related, sensors are too far apart and I didn't want to send analog signal through long wires... but you can also design a small amp board yourself to replace the original amp that links 3 sensors in parallel. I'd make it for you but it is not possible attm, even this post I have open for a while and typing a bit at a time 'cause I'm being interrupted non stop (and it is 2:30am here now

)

)- coax cable: already in use for the cables between sensors and amplifier since you had told me that before (and the instructions suggest shielded cables for this as well). Since I use the digital output only, I took normal cable to the Duet input however, but the cables are far away from any motor wiring.

the digital output is pretty hard to influence even with motor wires near it so that's ok... problem is that the old amp that's not ok... now, I don't remember if with digital output RRF fakes speed or not so that part might be irrelevant. For me that was a huge issue as I have proper detection with 20mm/sec but I could not make RRF probe at 20mm/sec in analog mode as then I'd have to tell it to do it much faster (Before it slows it down) and that would break other stuff (as 20mm/sec is max this printer can do Z, even 20mm/sec is not possible for the whole length of Z) ... anyhow, as I said 3 digital outputs are easily combined... if the "one" is trigger 3 input OR circuit solves the problem, if 0 is the trigger then 3 input AND ..

I contacted Precision Piezo (probably this question might end up at @DjDemonD if he is still active?) via their website.

I had a nice discussion with them and they were always happy to help but with Orion I got pretty disappointed with them for not sharing the new schematic. The PRC devs need few hours (cost nothing) to reverse their board so there's no protection from clones and not sharing the schematic is IMHO just bad .. but ..

Anyhow, you are using "old" digital only amp from what I assume so this:

TLC27L4CD will swing both ways and will have 1 for "triggered" so 3input or like SN74LVC1G332 after 3 amps and you can tweak each Andromeda using its own dedicated amp.... replacing that excuse for a trimmer (it is the cause of much frustration, the rated lifetime of those devices are 20 turns, so 20 times you move it and it's dead, having it on a vibrating machine ?!?!?!) so replacing VR2 with proper multiturn pot like

e.g. https://www.digikey.com/en/products/detail/bourns-inc/PV36W104C01B00/666503

-

May I chime in here? It's just a little self-promotion, so you'd been warned to read further

@arhi said in Two Precision Piezo boards in parallel on one input possible?:

VERY fast probing speed, if your Z speed is slow it will just not work

That's why I gave up on Piezo's.

But now imagine you had a barometric sensor which would trigger reliable, no matter how slow you move Z?I haven't thought of the Cat whisker as underbed sensor-array yet, but it would be nice to find a working solution for that scenario as well. (each sensor has the same I²C address, which is the only disadvantage I see) (*)

Excuse me, for trying to recruit some assistance in developing such sensor.//edit

*) The solution might be a number of aircussions below the bed, connected with tubes in series and one single baro-sensor to detect the touch. -

I would not agree they are "bad". Piezo is what it is. IMHO the sensors created by precisionpiezo Andromeda and Orion are pretty good (much better IMHO than stand-alone disks where the puny force on the wires will detach them from the disk along with a piece of disk coating)

Most issues I have (and you have as well from what I see) are the way we are using the technology. When you use the way they designed it, it works out of the box

No, the sensors themselves are really good. Any sensors measuring strain or deformation mounted beneath the bed have their disadvantages, simply due to their type of placement. They are simply in a place where forces are not... well, "focused", to put it simple (unsure which is the correct english wording here...). If you place a sensor into the hotend correctly there is no way for the contact force but to go through the sensor (in case of a piezo I count the deformation element it is glued onto as part of the sensor), and the lever arm always more or less stays the same.

In case of the bed however, there are at least two other ways - and lever arms change, depending on where you push. In theory, you always have the same result - in practice, there are various effects causing problems. It is the same as with several force transducers being mounted below let's say a crane or one mounted directly into the hook... Thus, even an ideal bed sensor array will not work as good as a hotend sensor. The question is always: does it work well enough anyway?

In my case, I tried to use them as close as possible to the way they were intended to be, but as I work within the restraints of my printer, that only works as well as it allows...I disagree with you here

and I have to say, I disagree without ANY proof

and I have to say, I disagree without ANY proof  but I am somehow sure that there is a way to incorporate a piezo-like sensor in this type of head mount without losing more than 5mm of Z space. [...]

but I am somehow sure that there is a way to incorporate a piezo-like sensor in this type of head mount without losing more than 5mm of Z space. [...] but since I actually gave up as even the cheap aliexpress bltouch knockoff give results that are consistent and repeatable, do not require thorough nozzle clean before probing and work "every time" ...You dont' know how that thing looks inside - there is not that much material there even if it looks massive

If you could get custom made piezo sensors that are not round for a decent price, it would be rather easy (but would need a complete redesign anyway) and could probably be done without losing z height. But a 20mm disc or even something larger would be really hard, even with redesigning the whole thing. As mentioned in the other thread we talked, there is exactly one place where I could drill a 2...3mm hole through the whole assembly for a - much elongated - BLTouch pin without interfering with something somewhere and letting the cable chain still move as it needs. And all these things need to stay in place...

If you could get custom made piezo sensors that are not round for a decent price, it would be rather easy (but would need a complete redesign anyway) and could probably be done without losing z height. But a 20mm disc or even something larger would be really hard, even with redesigning the whole thing. As mentioned in the other thread we talked, there is exactly one place where I could drill a 2...3mm hole through the whole assembly for a - much elongated - BLTouch pin without interfering with something somewhere and letting the cable chain still move as it needs. And all these things need to stay in place...

Hm, in case I need something SLS printed, I use Rapidobject. For Germany, they have good prices, and no fuss with customs. And the Alumide they offer is simply great

That is weird. I had a similar idea myself at the beginning, luckily I have 4ch scope (both digital and analog storage) and I looked at the signal from 3 and 4 andromeda's directly without amp and in my case they don't cancel out. The issue is just in how "sharp" the "touch" is in my case.

Yes, I had hoped for this, but even with just two channels on my old Tek, I can see the signal peaks with the overlayed vibration being something near λ/2 apart... I guess the resonance frequency of my heatbed fits much too good to its size...

For e.g. this is the test that works for me [...]

The test looks very much the same than the one I did, except that I used a Ø6mm plastic rod I had lying around (length around 30cm). To get a signal rising above the level of the vibration (i.e. something not canceling itself out) I needed to rise that one some five to 6 cm. No way to get such an impulse with my z axis. As soon as I split the sensors, a gentle tip with the finger was enough...Anyway, I have the Precision Piezo v2.85 amp (i.e. the latest variant they sell) in use - and I got feedback from them.

So here is the solution for anyone who might need it in the future: the digital output of v2.85 does indeed pull the signal line to ground - and that's it. Thus, you can simply wire two of these amplifiers (I would like to support them and not buy the chinese ripoffs) in parallel and that's it

Regarding the trimmer: yes, I understand why you don't like that thing lasting just 20 full turns. But on the other hand: the lighter (i.e. smaller) the part, the less problems with mechanical disturbances. These trimmers you suggest are in comparison relatively heavy and in my old company I learnt there were problems with those when being built stiffly into force transducers - they got killed or worn-out by the mechanical impulses over time in some cases. Thus, even if I had the space I would not mount that one directly benath my print bed facing downwards as I do with the amplifier - even if I don't know if the vibrations come anwhere near the critical level

That's why I gave up on Piezo's.

But now imagine you had a [barometric sensor]...I like the idea - but apart from the sealing problem, you would have to cope with the air getting hot and thus expanding as soon as someone turns on the heat bed - And this effect will continue for quite some time after the bed has reached its temperature, so I guess you need an amplifier that checks for pulses and discards any change benath a certain value per second - meaning you end up with something similar to a piezo (albeit requiring less speed). I would rather try some silicone oil or so which expands much less and minimise the volume of that to the absolute minimum.

I guess it might be easier to use the principle of piezo force transducers instead - these do not monitor the voltage peak of the piezo disc as "our" piezo amplifiers do but rather the electric charge created by the piezo. By doing so, you can even measure semi-static forces up to a certain point.

-

@neodue said in Two Precision Piezo boards in parallel on one input possible?:

you would have to cope with the air getting hot and thus expanding

The trick is to use a differential method. Just before you begin to probe, you read the pressure and then set the trigger point a fixed amount above that pressure. It's only theory until I get the sensor modules.

-

@neodue said in Two Precision Piezo boards in parallel on one input possible?:

If you could get custom made piezo sensors that are not round for a decent price

You can cut the big disks into any shape you like, they are rather easy to cut and they still work

These trimmers you suggest are in comparison relatively heavy and in my old company I learnt there were problems with those when being built stiffly into force transducers - they got killed or worn-out by the mechanical impulses over time in some cases.

I have them on the 2 printers for many years, no issues, omni also have it on his printer, also no issues (now he has printer for a year, not years so we'll see), all 3 printers have them on the head so much more vibrations than on the bed, no issues.. but yes, I do understand your pov. There are smaller multiturn trimmers that are rated for lot more than 20 turns and would be better choice but they are smd parts so would have to be designed into the board, almost impossible to just change the existing smd trimmer with a new one with different pinout... the through hole ones are possible as you can bend the wires any way you want

.... if I was designing the board I'd use those (smaller, lighter, cheaper to manufacture.. and still multiturn)

.... if I was designing the board I'd use those (smaller, lighter, cheaper to manufacture.. and still multiturn)So here is the solution for anyone who might need it in the future: the digital output of v2.85 does indeed pull the signal line to ground

If they kept true to their original statement and shared the schematic like they did for original board we could see that ourselves immediately...

-

The trick is to use a differential method. Just before you begin to probe, you read the pressure and then set the trigger point a fixed amount above that pressure. It's only theory until I get the sensor modules.

Okay, that might work - but you would zero it before every probing point then. Anyway, I would rather prefer something not relying on gases or liquids

You can cut the big disks into any shape you like, they are rather easy to cut and they still work

Depends, I think... I have no personal experience with this, but from what I read e.g. drilling them causes weird response curves in some cases.

There are smaller multiturn trimmers that are rated for lot more than 20 turns and would be better choice but they are smd parts so would have to be designed into the board, almost impossible to just change the existing smd trimmer with a new one with different pinout... the through hole ones are possible as you can bend the wires any way you want

.... if I was designing the board I'd use those (smaller, lighter, cheaper to manufacture.. and still multiturn)

.... if I was designing the board I'd use those (smaller, lighter, cheaper to manufacture.. and still multiturn)Agreed. When I solder something myself, I stick with THT, so I don't know what is available. But while I do not miss the multiturn feature, anything of similar size with a longer lifetime would be good indeed.

If they kept true to their original statement and shared the schematic like they did for original board we could see that ourselves immediately...

You are absolutely right there. However, I do understand they want to make life more difficult for copycats. Like this, someone who wants to copy the thing at least needs to buy and reverse engineer it - and does not get the schematic for free. It is not much of a hindrance, but it does help a bit. I have to admit I would do the same in their case.

But it would be good to note in the manual what the outputs do, and maybe remove the outdated schematic that only confuses the buyers. This is exactly what I suggested to them - let's see if they follow my input

For now, I will wait for my second amplifier.

-

@neodue said in Two Precision Piezo boards in parallel on one input possible?:

I have no personal experience with this, but from what I read e.g. drilling them causes weird response curves in some cases.

I do, lot of experience with piezo materials, using them to drive mirrors, etc ... the major issue with drilling is that you usually mess it up and break the piezo element due to the way drill work, if you could punch the hole out it would be much better... cutting it with a pcb cutter or big paper cutter produces very usable parts... major problem with these is that the "coating" you solder on is crap

.. ideally you should not solder but make contact using some springs

.. ideally you should not solder but make contact using some springsAgreed. When I solder something myself, I stick with THT, so I don't know what is available. But while I do not miss the multiturn feature, anything of similar size with a longer lifetime would be good indeed.

I missed multiturn a lot as making piezo trigger just right is super hard with the %$#^$# one used here, and every time you reassemble the head you need to tweak it again (and after few times it is dead) ... soldering smd is simple, I prefer smd to pth as with pth I need to hold part on one side and solder on other, I need to drill the pcb etc etc... too much hassle, smd is super easy (0805 and bigger, I do hate those 0402 and smaller parts

but when you design it yourself you go with 0805 and 1206 and you can solder that easier than pth with just a little bit practice) ... anyhow with jlcpcb being so cheap these days I let them do all the soldering for me

but when you design it yourself you go with 0805 and 1206 and you can solder that easier than pth with just a little bit practice) ... anyhow with jlcpcb being so cheap these days I let them do all the soldering for me  as it is usually cheaper to get soldered board from them than just buying parts locally

as it is usually cheaper to get soldered board from them than just buying parts locallyYou are absolutely right there. However, I do understand they want to make life more difficult for copycats. Like this, someone who wants to copy the thing at least needs to buy and reverse engineer it - and does not get the schematic for free. It is not much of a hindrance, but it does help a bit. I have to admit I would do the same in their case.

TBH I think that's BS

Their board is cheap so purchasing their bord is not a problem for cloner.

Reverse engineering a 16x10cm 6 layer board "full of parts" with extracting HEX and converting HEX to ASM, so- HEX

- gerbers for all 6 layers

- Schematic with part numbers and values

cost 450eur

I guess reverse engineering Orion board at same company cost less then Orion board

so they are not preventing cloners nor making anything harder for cloners. The only ones they are preventing are advanced users.

so they are not preventing cloners nor making anything harder for cloners. The only ones they are preventing are advanced users.For now, I will wait for my second amplifier.

you sure 2 will do? why didn't you go with 3 so you can have 100% one sensor one amp so there's no way they can influence each other? You know how they say if it is worth doing it is worth overdoing

-

@arhi said in Two Precision Piezo boards in parallel on one input possible?:

I do, lot of experience with piezo materials, using them to drive mirrors, etc ... the major issue with drilling is that you usually mess it up and break the piezo element due to the way drill work, if you could punch the hole out it would be much better... cutting it with a pcb cutter or big paper cutter produces very usable parts... major problem with these is that the "coating" you solder on is crap

.. ideally you should not solder but make contact using some springs

.. ideally you should not solder but make contact using some springsInteresting - I never had a problem with soldering on them. But I never dared to cut them. I'll remember your advice and try when there is a need again

I missed multiturn a lot as making piezo trigger just right is super hard with the %$#^$# one used here, and every time you reassemble the head you need to tweak it again (and after few times it is dead) ... soldering smd is simple, I prefer smd to pth as with pth I need to hold part on one side and solder on other, I need to drill the pcb etc etc... too much hassle, smd is super easy (0805 and bigger, I do hate those 0402 and smaller parts

but when you design it yourself you go with 0805 and 1206 and you can solder that easier than pth with just a little bit practice) ... anyhow with jlcpcb being so cheap these days I let them do all the soldering for me

but when you design it yourself you go with 0805 and 1206 and you can solder that easier than pth with just a little bit practice) ... anyhow with jlcpcb being so cheap these days I let them do all the soldering for me  as it is usually cheaper to get soldered board from them than just buying parts locally

as it is usually cheaper to get soldered board from them than just buying parts locallyAh, JLC were the ones I had checked as well some time ago, but they don't like Eagle files - and I did not want to learn using another software for what little I do... therefore I use Aisler in case the need arises - but with drilled holes. A little old-fashioned I am, I know

When it came to adjusting, it seems I am lucky: I set it once - and despite disassembling and reassambling over and over to find out what my problem was, I almost never had to touch the potentiometer again. I cross my fingers it stays like that

TBH I think that's BS

Their board is cheap so purchasing their bord is not a problem for cloner. [...]It is always difficult with such rather cheap electronics - unless you use your own custom ICs and remove the labels on all the other ones, you are never safe. As I said, it is a hindrance, but not a large one. If someone really wants to copy you, he will. Others that just search for an easy way might go on and look for something else. At least the chinese copys I found are not the latest version, so it seems at least they do not care enough or don't think it's worth the investment. IMHO the advanced user needs a clear specification of what the output does exactly (and this is what they ought to provide indeed), but not necessarily the schematic.

you sure 2 will do? why didn't you go with 3 so you can have 100% one sensor one amp so there's no way they can influence each other? You know how they say if it is worth doing it is worth overdoing

Haha

No, I will stick with two. "As good as necessary for the task" is good enough for me there - otherwise I would have followed your suggestion and built my own amplifier

-

@neodue said in Two Precision Piezo boards in parallel on one input possible?:

Interesting - I never had a problem with soldering on them. But I never dared to cut them. I'll remember your advice and try when there is a need again

no problem soldering on them, the problem is not tearing the wire with solder joint from them taking the whole coating with that solder with them

no problem soldering on them, the problem is not tearing the wire with solder joint from them taking the whole coating with that solder with them  ... as the metalized coating you solder on is vapored on or added by some other chemical reaction and is super thin and weak, a little pull on the wire and off it goes

... as the metalized coating you solder on is vapored on or added by some other chemical reaction and is super thin and weak, a little pull on the wire and off it goes  ...

...purchase a box of them from PRC and play with them, cut, drill, it's cheap and they are very versatile sensors for many things.. if that interest you, if you only wanna solve the probing issue, you probably already did

Ah, JLC were the ones I had checked as well some time ago, but they don't like Eagle files - and I did not want to learn using another software for what little I do... therefore I use Aisler in case the need arises - but with drilled holes. A little old-fashioned I am, I know

Why would you send eagle files to anyone? Eagle can export GERBER as well as any other PCB editor, Gerber is the manufacturing format. Anyhow I think both seedstudio and dirtypcb (Ian from dang.prot.) accept raw eagle files and they'll export gerbers for you for processing them, only they don't have cheap assembly with cheap pcb's

At least the chinese copys I found are not the latest version, so it seems at least they do not care enough or don't think it's worth the investment.

they don't care, no one is buying them, they are copying bltouch and other stuff ppl are buying ... too many issues with PP for them to care about. Again a reason not to withhold schematic from advanced users. On the other hand, they are adults, they can do whatever they like, not my problem. I wish them all the success in business and life.

No, I will stick with two. "As good as necessary for the task" is good enough for me there - otherwise I would have followed your suggestion and built my own amplifier

actually the best solution is to have bed that do not need leveling but that's another can of worms

-

I think that goes too much offtopic now - I'll send you a PM

-

Just in case somebody stumbles over this thread and has the same problem:

In the meantime I got the second amplifier and included it in my bed sensors.

Dividing the three piezo bed sensors on two different amplifiers - both (digital) outputs being connected in parallel to the input of the Duet - worked perfectly for me. All problems I had with the bed sensors are gone and contact sensing works great even with the slow z axis of my printer.

Thus, I can recommend this method whenever there is a crosstalk problem with piezo sensors.

-

@neodue said in Two Precision Piezo boards in parallel on one input possible?:

worked perfectly for me. All problems I had with the bed sensors are gone and contact sensing works great even with the slow z axis of my printer.

If you share the mounts for the sensors for your printer that can help a lot for someone using the same/similar printer

-

@arhi I had already posted the setup I used

You can see it here: https://forum.duet3d.com/topic/14477/piezo-board-with-4-sensors/29The bed screw holes of the original bed support (a shaped sheet metal plate) were drilled open to let the bed springs through, and I added additional screw holes to hold the added aluminium profiles in place and stiffen the original bed support.

The basic "mount" for each sensor is a more or less L-shaped aluminium profile I had lying around (a rest of the cable channel for our TV). You can replace it with any aluminium L profile that has at least the following dimensions: material thickness 1,2mm, long "leg" of L profile 24mm, short "leg" of L profile 8mm.

I cut fitting holes into the material as needed (two screws for the Andromeda, one larger for the bed spring, another screw hole for screwing the whole thing onto the original part and making the assembly stiffer than it was before and two M2 threaded holes for some sensor covers I printed from PETG) and used clinch nuts to get stable threads for mounting the Andromeda sensors. Since I mounted these aluminium plates on top of the original sheet metal bed support so save some millimeters (as noted in the other thread, there is not much available space in my printer), I used DIN 988 adjusting washers to even out the heights when I screwed on the sensors.

In order to catch the tolerances, I mounted everything loosely first, then added the bed and only then tightened all screws with a little bit of Loctite (be careful not to let that stuff get onto the epoxy material of the PCB, in some cases this causes trouble some years later).

That's it, basically... sadly nothing another user could use 1:1 I am afraid - but It's a concept. If I can help you (or anyone else) with details please feel free to ask or send me a message

-

@neodue ah, I forgot about that post, I had them printed and mounted on the bed as more than enough space here, I just believe since it is solved now as much info as possible in single place so when someone tomorrow ends up reading it they will know how to reproduce

-

Firstly, I must apologize for coming a month late to this party but I only just stumbled across this thread on a Google search for something else.

It sounds like the problem is something I came across and did a bit of research on. The problem is not with piezo sensors, but with the dynamic behavior of the bed being unpredictable in much the manner of the sand plates (Chladni plates) beloved of high school science demonstrations.

I found two ways to combat this:-

-

The underbed sensors are much more predictable if they are placed beyond the periphery of the probing area - having three closely matched piezos helps a lot as well.

-

Use a single underbed sensor to get the accurate nozzle contact and only probe directly above this sensor. A second sensor of the contact type such as a BLTouch is used got get other data for bed leveling/mapping. This does require that there is some way to select the sensor to tbe used for each purpose.

I have had a great deal of success with the second method and am able to get results with an accuracy of better than 3 microns at all points on the bed.

More info on this at:-

https://reprap.org/forum/read.php?424,865620

https://reprap.org/forum/read.php?424,874556

https://reprap.org/forum/read.php?1,635075,881434#msg-881434Mike

-

-

@leadinglights Thanks for the remark with the Chladni plates! I never heard of these before (not common part of school physics when I was a pupil at least), but this fits perfectly to what I observed with my oscilloscope.

Since my Neo print head would need complete redesign to include a piezo up there, I stuck with reading out the sensors that got crosstalk separately and am quite happy with the result. I see some repeatable measurement errors due to the varying flexibility of the print bed, but that is fine for me for now.

Hm... now that I think of it, it might be worth a feature request to be able to substract a given height map from a newly measured one... by doing this you could remove such measurement errors...